CNC DRILLING AND TAPPING MACHINE CENTER

Vt series CNC tapping machine center is a vertical drilling center independently designed and developed by our company. The CNC drilling and tapping machine center has the structural characteristics of high speed, high precision, high rigidity, and high reliability. CNC drill tap machine center can work continuously and normally under specified environmental conditions with stable precision. The cnc industrial machine tool is widely used in the 3C industry, 5g, it, aviation, aerospace, auto parts, small mold processing, medical devices, and other industries, especially for high-efficiency processing of high-yield parts and non-ferrous metals. Contact our cnc machining center factory for more information!

CNC TAPPING MACHINE CENTER SPECIFICATION

VT60B CNC Drill Tap Machine Center

X-axis Travel mm 1100

Y-axis Travel mm 600

Z-axis Travel mm 350

From spindle nose to worktable face mm 250~600

Distance from spindle center to column 468

Worktable Size mm 1200*600

A large load of workbench kg 400

T-slot mm 14H7*5*120

X/Y/Z-axis Rapid Traverse m/min 60/60/60

Feedrate speed

X/Y/Z -axis Cutting Speed m/min 20/20/20

acceleration 1g

Spindle type Direct connection

Spindle taper BT30

Spindle speed rpm 12000

Main motor power KW 3.7/7.5

Spindle Torque N.M 23.6/47.7

X/Y/Z Positioning Accuracy (half-closed loop) mm 0.008

X/Y/Z Repeatability Accuracy (half-closed loop) mm 0.005

ATC Turret type

ATC Capacity 21

Larger tool size mm φ100/φ140/250

Larger tool weight kg 3

Air source pressure MPa 0.65

Power capacity KVA 250~600

Machine size (length*width*height) mm 2760*2600*2720

Machine weight kg 6000

Most Required CNC Machines

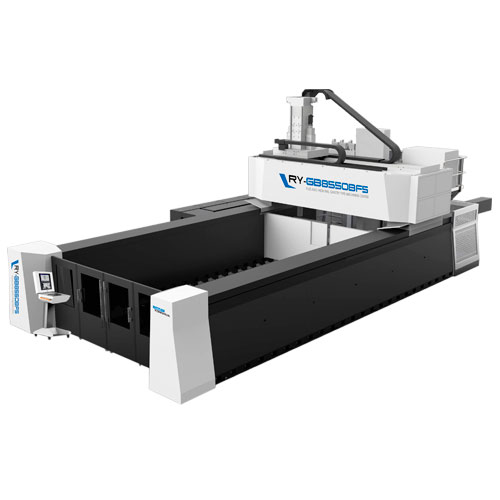

5 axis gantry type machining center

Horizontal boring and milling center

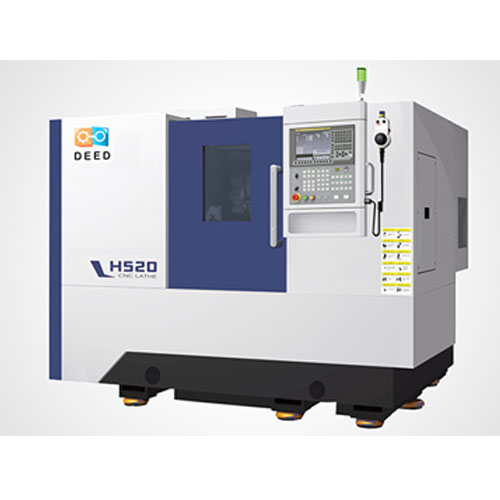

CNC horizontal turning center

Planer type horizontal boring machine

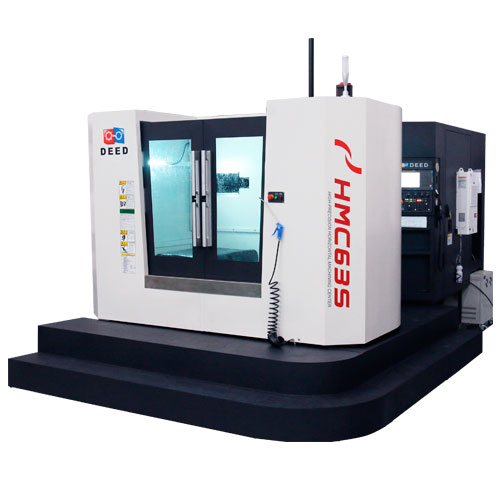

Horizontal machining center with pallet changer

Advantages of Using CNC Drilling and Tapping Machine

CNC drilling and tapping machines offer numerous advantages over traditional manual drilling and tapping methods. These machines combine the precision and efficiency of computer numerical control (CNC) technology with the versatility of drilling and tapping operations. Let's explore the key advantages of using CNC drilling and tapping machines:

a. Precision and Accuracy: CNC drilling and tapping machines provide exceptional precision and accuracy in hole drilling and tapping operations. The computer-controlled automation ensures consistent and repeatable results, eliminating human errors and ensuring tight tolerances. This precision is crucial in industries where accuracy is paramount, such as aerospace, automotive, and electronics.

b. Increased Efficiency: CNC drilling and tapping machines significantly improve efficiency in drilling and tapping operations. These CNC tapping machines can perform multiple operations in a single setup, reducing the need for manual repositioning and tool changes. The automation streamlines the production process, reduces cycle times, and increases productivity.

c. Versatility: CNC drilling and tapping machines are highly versatile, capable of handling various workpieces, materials, and hole sizes. They can accommodate different drill bit and tap sizes, allowing for a wide range of hole diameters and thread types. The versatility of these CNC tapping machines makes them suitable for diverse industries and applications.

d. Reduced Labor Costs: The automation provided by CNC drilling and tapping machines reduces the need for manual labor. Once the program is set, the CNC tapping machine can operate autonomously, requiring minimal human intervention. This reduces labor costs and allows operators to focus on other tasks, maximizing overall productivity.

e. Flexibility in Hole Patterns: CNC drilling and tapping machines offer flexibility in creating hole patterns. They can easily create holes with precise spacing, angles, and patterns, including holes on irregular or curved surfaces. This flexibility is particularly beneficial in industries such as woodworking, metal fabrication, and PCB manufacturing.

f. Improved Safety: CNC drilling and tapping machines prioritize operator safety. These CNC tapping machines are equipped with safety features such as automatic tool changers, emergency stop buttons, and protective enclosures. The automation reduces the need for manual handling of tools, minimizing the risk of accidents and injuries.

Deed CNC Drilling and Tapping Machine for Sale

The Deed CNC drilling and tapping machine is a reliable and high-performance solution for precise hole drilling and tapping operations. This CNC drill tap machine is designed to deliver efficiency, accuracy, and versatility, making it suitable for a wide range of industries. Let's explore some key features and benefits of the Deed CNC drilling and tapping machine for sale:

a. High Precision: The Deed CNC drilling and tapping machine ensures high precision in hole drilling and tapping operations. It incorporates advanced control systems and servo motors to achieve precise positioning and movement. This precision guarantees accurate hole sizes, thread depths, and pitch consistency.

b. Fast and Efficient Operation: The Deed CNC drilling and tapping machine is equipped with a high-speed spindle and rapid tool changing capabilities, enabling fast and efficient operation. The CNC drill tap machine can quickly switch between drilling and tapping tools, reducing cycle times and maximizing productivity.

c. User-Friendly Interface: The Deed CNC drilling and tapping machine features a user-friendly interface that allows operators to program and control the CNC drill tap machine with ease. The intuitive control panel and software enable seamless operation and programming, even for users with limited CNC experience.

d. Versatile Applications: The Deed CNC drilling and tapping machine offers versatility in drilling and tapping applications. It can handle a wide range of materials, including metals, plastics, and composites. The CNC drill tap machine supports various hole sizes, thread types, and hole patterns, catering to diverse industry needs.

e. Robust Construction: The Deed CNC drilling and tapping machine is built with a robust and durable structure to ensure long-term reliability. The machine's stability and rigidity contribute to high precision and consistent performance even during heavy-duty operations.

f. After-Sales Support: Deed provides excellent after-sales support for its CNC drilling and tapping machines. This includes technical assistance, maintenance services, and spare parts availability, ensuring smooth operation and minimizing downtime.

Application of CNC tapping machine in Manufacturing

CNC tapping machines have revolutionized the manufacturing industry with their precision, efficiency, and versatility. These CNC drilling and tapping machines are designed to automate the tapping process, which involves creating internal threads within holes on various workpieces. The application of CNC tapping machines in manufacturing has significantly improved production processes across diverse sectors.

One key advantage of CNC tapping machines is their ability to consistently produce accurate threads, ensuring optimal fit and functionality of assembled components. They eliminate the potential for human error, resulting in uniform thread quality and reduced scrap rates. Additionally, these machines are highly programmable, enabling manufacturers to easily switch between different thread sizes and specifications, thus enhancing production flexibility.

In industries such as automotive, aerospace, and electronics, where intricate components with precise threading are vital, CNC tapping machines shine. They expedite production cycles, decrease labor costs, and enhance overall throughput. Moreover, by minimizing manual intervention, these CNC drilling and tapping machines enhance worker safety and reduce the risk of injuries associated with traditional tapping methods.

CNC tapping machines play a pivotal role in modern manufacturing by streamlining the thread creation process. Their accuracy, programmability, and adaptability make them indispensable in industries requiring intricate threading, ultimately contributing to higher quality end products and improved operational efficiency.

在线联系供应商

Other supplier products

| VERTICAL TURNING CENTER SPECIAL FOR WHEEL HUB | This cnc vertical turning machine tool takes the common 14-26 inch Kaba wheel hub rough and fine turning as the main processing object and has the ... | |

| Vertical Machining Center | High-performance Milling Provides professional solutions for different services Our Vertical machining centers mainly include VMC and VL two se... | |

| HMC-S SINGLE-PALLET HORIZONTAL MACHINING CENTER | DEED horizontal machining center with pallet changer mainly used for the processing of box, shell, and special-shaped parts in automobiles, motorcy... | |

| 5 AXIS CNC GANTRY TYPE MACHINING CENTER | 600*600mm large cross-section ram of 5 Axis CNC gantry type machining center to ensure that even when the ram is overhung, the gantry CNC 5 axis ga... | |

| VL-SERIES VERTICAL MACHINING CENTER | VL series vertical machining center is a small and medium-sized vertical machining centerdesigned by Germany and made in China. It mainly aims at t... |