HBC SERIES CNC HORIZONTAL BORING AND MILLING CENTER FOR SALE

HBC Series is our CNC horizontal boring and milling machine. According to the different sizes, we have HBC1116 CNC boring machine and HBC1316 CNC horizontal boring machine. We introduce German mineral casting material for our horizontal boring and milling center base and column. CNC horizontal borer has better shake absorption and Low thermal expansion. Worktable, sliding seat, and headstock are supported by heavy-duty roller linear rails to ensure cnc boring milling machine high rigidity and reduce the weight of moving parts. Choose Deed CNC, one of the top horizontal boring mill manufacturers.

HBC SERIES HORIZONTAL BORING AND MILLING MACHINE SPECIFICATION

Model HB1116CNC horizontal boring and milling center

Boring Shaft Diameter mm 110

Taper shank type BT50

Spindle motor kW 22/26

Maximum torque Nm 2000

Maximum speed rpm 2000

NC turntable Working table m 1200×1400

Position " ±8

Repeat Position " ±4

Max load Kg 3000

trip X-axis travel mm 1600

Y-axis travel mm 1200

Z-axis travel mm 1200

W axis travel mm 600

Feed rate Workbench horizontal (X) mm/min 2-6000

The vertical headstock (Y) mm/min 2-6000

Vertical column (Z) mm/min 2-6000

Boring shaft axial (W) mm/min 2-2000

Fast-moving speed Workbench horizontal (X) mm/min 15000

The vertical headstock (Y) mm/min 15000

Vertical column (Z) mm/min 15000

Boring shaft axial (W) mm/min 3000

HBC1316 CNC horizontal boring and milling center

Model HB1316CNC horizontal boring and milling center

Boring Shaft Diameter mm 130

Taper shank type BT50

Spindle motor kW 22/26

Maximum torque Nm 2000

Maximum speed rpm 2000

NC turntable Working table m 1200×1400

Position " ±8

Repeat Position " ±4

Max load Kg 3000

trip X-axis travel mm 1600

Y-axis travel mm 1200

Z-axis travel mm 1200

W axis travel mm 600

Feed rate Workbench horizontal (X) mm/min 2-6000

The vertical headstock (Y) mm/min 2-6000

Vertical column (Z) mm/min 2-6000

Boring shaft axial (W) mm/min 2-2000

Fast-moving speed Workbench horizontal (X) mm/min 15000

The vertical headstock (Y) mm/min 15000

Vertical column (Z) mm/min 15000

Boring shaft axial (W) mm/min 3000

Most Required CNC Machines

5 axis gantry type machining center

CNC drill tap machine

CNC horizontal turning center

Planer type horizontal boring machine

Horizontal machining center with pallet changer

Technology Upgrade of HBC Series Horizontal Boring and Milling Center

In the realm of machining excellence, the HBC Series has carved its niche as a symbol of technological prowess and innovation. Focused on enhancing performance, precision, and user experience, the HBC Series has undergone a remarkable technology upgrade, positioning it at the forefront of CNC horizontal boring and milling centers.

The HBC Series, comprising the HBC1116 CNC horizontal boring machine and the HBC1316 CNC horizontal boring machine, stands as a testament to relentless engineering refinement. At its core lies the incorporation of German mineral casting material for the base and column. This choice embodies a fusion of tradition and modernity, elevating the machine's foundational strength while embracing cutting-edge advancements.

This infusion of German mineral casting material results in an inherent vibration-damping property, effectively minimizing shakes and oscillations during operation. The material's low thermal expansion further ensures dimensional stability under varying temperature conditions, contributing to impeccable accuracy and repeatability. Such upgrades fundamentally transform the HBC Series horizontal boring and milling center into an exemplar of stability, even in the most demanding machining scenarios.

The metamorphosis doesn't halt there; the worktable, sliding seat, and headstock of the HBC Series horizontal boring and milling center have undergone meticulous reengineering. Heavy-duty roller linear rails now underpin these vital components, instilling a heightened level of rigidity that translates into unparalleled machining precision. This design overhaul not only fortifies the machine's structure but also reduces the weight of moving parts, culminating in smoother and swifter operations.

In the ever-evolving landscape of manufacturing, the HBC Series horizontal boring and milling center ' technology upgrade ensures that it remains a stalwart companion to industries that demand uncompromising excellence. Its amalgamation of superior materials, advanced engineering, and precision-driven enhancements cements the HBC Series horizontal boring and milling center as a driving force behind productivity and innovation.

Design Ideas of HBC Series Horizontal Boring and Milling Center

The HBC Series horizontal boring and milling center, a paragon of engineering ingenuity in the realm of CNC horizontal boring machines, harmonizes cutting-edge technology with meticulous design. Beyond its impressive functional capabilities, the HBC Series boasts an aesthetic and ergonomic framework that exemplifies form meeting function.

The HBC1116 CNC horizontal boring machine and its counterpart, the HBC1316 CNC horizontal boring machine, stand as avatars of design finesse. The machines' exterior exudes a harmonious blend of sophistication and robustness, reflecting the industrial strength that resides within. A carefully curated balance of sleek lines and strategic contours not only enhances the machines' visual appeal but also optimizes their spatial footprint, enabling efficient placement within diverse manufacturing environments.

The incorporation of German mineral casting material for the base and column serves as a testament to the series' commitment to marrying tradition with innovation. This distinctive choice, apart from its technical advantages, bestows a tactile and visual uniqueness that resonates with those who appreciate the amalgamation of craftsmanship and cutting-edge engineering.

The HBC Series' design extends beyond aesthetics to ensure an ergonomic and user-centric experience. The positioning of controls, accessibility to critical components, and intuitive interface design collectively reaffirm the user's centrality. Every interaction with the machine is designed to be intuitive, facilitating seamless operation while minimizing the learning curve for both novices and experts.

In an industry where precision is paramount, the HBC Series horizontal boring and milling center design embraces the significance of stability. The incorporation of heavy-duty roller linear rails for the worktable, sliding seat, and headstock not only enhances rigidity for impeccable accuracy but also demonstrates a design philosophy that emphasizes uncompromising quality.

Beyond being a powerhouse of machining prowess, the HBC Series horizontal boring and milling center stands as an embodiment of meticulous design thinking. It showcases how form and function can coalesce to create not just machines, but instruments of precision, efficiency, and visual delight. The HBC Series' design ideas echo its commitment to being a pinnacle of CNC horizontal boring and milling centers, setting a benchmark that others aspire to emulate.

In a world driven by engineering marvels, the HBC Series horizontal boring and milling center reigns supreme as a testament to what happens when innovative technology and visionary design converge. Choose Deed CNC, and embrace the embodiment of design and engineering excellence that defines the HBC Series - your partner in shaping the future of manufacturing.

Other supplier products

|

|

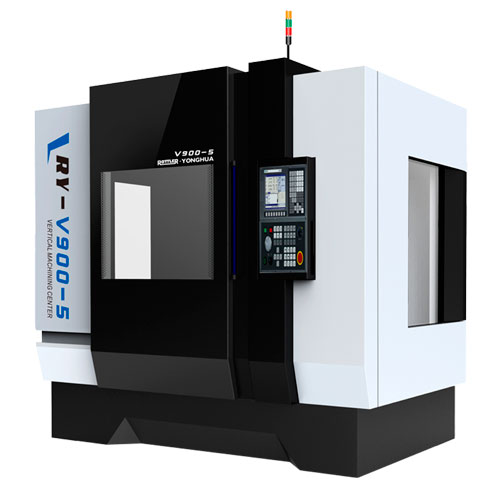

VL-SERIES VERTICAL MACHINING CENTER |

VL series vertical machining center is a small and medium-sized vertical machining center designed by Germany and made in China. It mainly aims at ... |

|

|

5 AXIS VERTICAL MACHINING CENTER |

Vertical type five axis vmc machineis a high-end 5-axis linkage machine tool that developed after taking in the German advanced technology. Its fea... |

|

|

CNC MACHINING CENTER |

CNC milling machine is automatic processing equipment developed on the basis of a general milling machine. Their processing technology is basically... |

|

|

VL-SERIES VERTICAL MACHINING CENTER |

VL series vertical machining center is a small and medium-sized vertical machining center designed by Germany and made in China. It mainly aims at ... |

|

|

Vertical Machining Center |

China vertical machining center

Our vmc machine typesmainly include VMC and VL two series, VMC series include VMC50B VMC milling machine, VMC50C V... |

供应产品

Same products