Stretch Forming

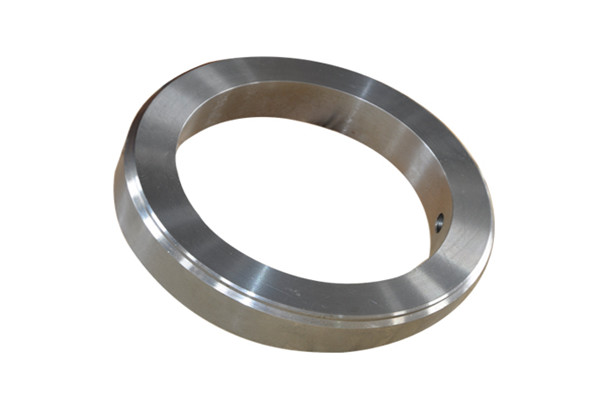

Sheet metal stretch formingis a technology to stretch the mental into different shaped mental parts. It also will improve the structure of the unloading part of the forming mold, which can automatically unload the parts under the action of the spring.

As one ofprofessional stretch forming companies, stretch forming is a essential part of industrial metal stamping.

ETCN metal fabrication service china will try our best to provide our client with the most qualified sheet metal stretch forming aluminumservices and welcome to your visit.

Advantage of Stretch Forming

Stretch forming is a technique to improve the unloading structure of forming molds which includes stretch forming aluminum sheet; it improves the efficiency of unloading parts from forming molds and can make the structure of stretch forming molds simple; stretch forming molds are composed of concave, convex molds, and blank holders. The top plate, springs, and screws are composed; advantages of stretch forming applicationsare: under the action of the spring, it can automatically unload the parts, improve the unloading efficiency, without damaging the parts, the mold structure is simple, reduce the manufacturing cost, shorten the manufacturing cycle, and convenient to use and maintain.There are many stretch forming applications in sheet mental stretching.

If you want to know more kinds of stretch forming aluminum extrusions, please visit our website.

As a leading precision CNCmachining Chinamanufacturing company in China, ETCN offers high-precision CNC machining and manufacturing servicescovering different fields in China CNC grinding services like iron metal casting services, CNC machining (including plastic) services, CNC milling services, CNC punching services and CNC turning services.

在线联系供应商

Other supplier products

| CNC Milling | CNC milling processing is suitable for precision and complex parts processing, periodically repeated production parts processing, multi-station, mu... | |

| CNC Boring | CNC boringis used for the shaft sleeve in the transmission shaft of large equipment, and the tolerance of the bearing position is +0.03mm. After we... | |

| Sheet Metal Fabrication | Sheet metal is a comprehensive cold working process for metal sheets (usually below 6mm), including shearing, punching/cutting/compounding, folding... | |

| CNC Grinding | After CNC milling or CNC turning forming, the surface roughness and behavior tolerance requirements of products are completed by CNC grinding, and ... | |

| Cold Forging | As a professional part former cold forgingmanufacturer, ETCN provides our clients with precision cold forging die with different types of cold forg... |