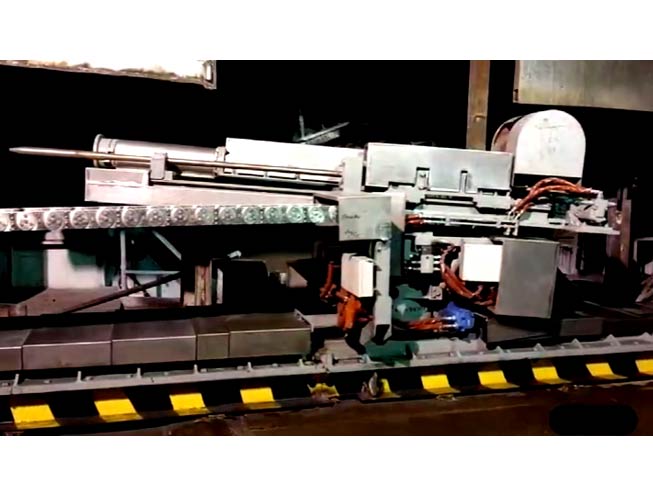

Furnace Taphole Drilling Machine

The manipulator is applied to the opening and plugging of the slag port in a copper smelting furnace. According to the copper smelting furnace slag port manual operation process and used tools, we developed hole digging robotic manipulator arm, which uses automatic control intelligent operation, instead of manual work in high risk and high pollution environment.

Introduction of Furnace Tap Hole Machine

The furnace tap hole machine is generally composed of gun tube device, advance and retreat device, rotation device and angle adjustment device etc. It is used for opening and plugging after smelting in copper anode furnace copper smelting furnace. There are three structural forms of furnace tapping machine: electric, hydraulic and pneumatic. The furnace drilling and tapping machinedeveloped by CIC adopts automatic control and intelligent operation, which can replace manual work in high-risk and high pollution environment. In the meantime, they are also can be applied in copper mining process.

The tapping device comprises a base, a track, strip teeth and meshing mobile gears; The upper part of the base is fixedly provided with a track, the strip teeth are fixedly arranged in the middle of the upper part of the base, and the strip teeth are provided with teeth; The meshing moving gear is arranged on the strip teeth, and the meshing moving gear engages with the strip teeth; The driven wheel is fixedly arranged at the right position of the meshing moving gear, the driving wheel is fixedly arranged at the upper position of the driven wheel, and the driving motor is fixedly arranged at the right position of the driving wheel; The support body is arranged on the track, and the support body moves in contact with the track.

The rotary mechanism is fixedly arranged on the support body, and the support column is fixedly arranged on the upper part of the rotary mechanism; The rotating shaft is fixedly arranged in the connecting body connecting the support column with the open arm support and the closed arm support as a whole; The bottom of the first hydraulic cylinder is fixedly connected with the support column, and the upper part is fixedly connected with the right end of the open arm support; The bottom of the second hydraulic cylinder is fixedly connected with the support column, and the upper part is fixedly connected with the right end of the plugging arm support; The mobile device is fixedly arranged on the open arm support and the closed arm support respectively; The opening arm is fixedly arranged on the opening arm support, and the plugging arm is fixedly arranged on the plugging arm support; The mud taking container is fixedly arranged at the rear side of the plugging arm, and the extrusion forming device is fixedly arranged at the front side of the plugging arm; There are two hydraulic pipe retracting and releasing wheels for retracting and releasing the hydraulic pipe, one is fixedly arranged at the upper position of the right end of the opening arm, and the other is fixedly arranged at the upper position of the right end of the plugging arm.

Techinical Specification of Auto Drilling and Tapping Machine

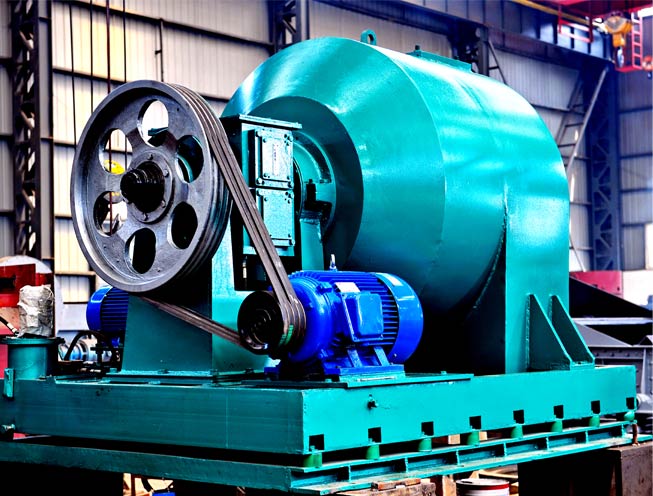

Hydraulic System of Furnace Tap Hole Machine

Pump pressure 90kgf/cm², Max 110kgf/cm², 18.5 kW ×2... One of them is standby. Proportional valve control is adopted.

Automatic Control and Operation of Furnace Tap Hole Machine

It adopt PLC control system, and man-machine dialogue mode is adopted for operation. The operating handle is the miniaturized model of the whole equipment, and the action process of the field equipment can be operated in the control room.

Features of Furnace Tap Hole Machine

◉ The driving wheel is fixedly connected with the power output shaft of the driving motor, and the driven wheel and the meshing moving gear are fixed as a whole through the connecting shaft.

◉ The rotary mechanism comprises a rotary disc, which is a circular rotary body. A hydraulic motor a for driving the rotary disc to rotate is arranged inside the rotary disc, and the hydraulic motor a is fixedly connected with the hydraulic station through a hydraulic pipe.

◉ The mobile device comprises a track, the track is fixedly arranged at both sides of the open arm support and the closed arm support, the hydraulic motor B is fixedly arranged at the right end of the open arm support and the closed arm support, the power output end of the hydraulic motor B is fixedly provided with a driving gear, and the driven gear is fixedly arranged at the left end of the open arm support and the closed arm support, One of the moving gears is fixedly arranged at the bottom of the third hydraulic cylinder of the open arm, and the other is fixedly arranged at the bottom of the mud plugging forming cylinder of the plugging arm; The drive gear and the driven gear are connected and transmitted through a chain.

◉ The tapping arm comprises a third hydraulic cylinder, the third hydraulic cylinder is arranged on the track of the mobile device through a connecting block at the bottom, the third hydraulic telescopic rod is fixedly arranged at the left end of the third hydraulic cylinder, and the steel drill rod is fixedly arranged at the left position of the third hydraulic telescopic rod; The right support block is fixedly arranged at the left end of the steel drill, the left support block is fixedly arranged at the left end of the steel drill, the steel drill passes through the right support block and the left support block, the right support block and the left support block are respectively arranged on the track of the mobile device, and the right support block and the left support block move in contact with the track.

◉ The plugging arm comprises a fourth hydraulic cylinder, the fourth hydraulic cylinder is fixedly arranged on the track of the mobile device through the connecting block, the fourth hydraulic telescopic rod is fixedly arranged on the left side of the fourth hydraulic cylinder, the piston is fixedly arranged on the left side of the fourth hydraulic telescopic rod, the mud plugging forming cylinder is fixedly arranged on the left side of the fourth hydraulic telescopic rod, and the piston extends into the mud plugging forming cylinder.

◉ The mud taking container comprises a base, the base is fixedly arranged at the bottom of the supporting square steel, the mud holding box is fixedly arranged at the upper part of the supporting square steel, the mud holding box is a hollow square, and the mud taking port is fixedly arranged at the right side of the mud holding box.

◉ The extrusion forming device comprises a bottom plate, the bottom plate is fixedly arranged at the bottom of the support steel body, the support handle and the support steel body are vertically and cross arranged, the right end of the support handle is fixedly provided with a shaper, and the shaper is a hollow round platform shape.

Maintenance Methods of Furnace Tap Hole Machine

Select suitable cleaning oil

Clean oil plays the role of pressure transmission, lubrication, cooling and sealing in the furnace tap hole machine. Improper selection of cleaning oil is the main reason for early failure and durability decline of furnace tapping machine. Clean oil shall be selected according to the needs of the machine. When alternative oil needs to be used under special circumstances, its performance shall be the same as that of the original brand. Cleaning oils of different brands cannot be mixed to prevent chemical reaction and performance change of cleaning oil. Dark brown, milky white and peculiar smell cleaning oil is deteriorated oil and cannot be used.

Prevent solid impurities from mixing into the furnace tapping machine

Pure clean oil is the life of the opening and plugging machine. There are many precision coupling parts in the opening and plugging machine, such as damping holes, gaps, etc. If solid impurities invade, the precision coupling will be strained, hairpin, oil duct blockage, etc., which will endanger the operation of the opening and plugging machine. The ways for general solid impurities to invade the opening and plugging machine are: clean oil is not clean; Dirty refueling tools; Careless refueling, repair and maintenance; Desquamation of hydraulic components, etc. Solid impurities can be prevented from invading the system from the following aspects:

The cleaning oil must be filtered and filled, and the refueling tools shall be reliably cleaned. Do not remove the filter at the fuel tank filler for the sake of refueling speed. Refueling personnel shall use clean gloves and work clothes to prevent solid impurities and fiber impurities from falling into the oil.

If it is necessary to use wiping materials and hammers, wiping materials without fiber impurities and special hammers with rubber attached to the striking surface shall be selected. Hydraulic components and hydraulic hoses shall be carefully cleaned and assembled after drying with high-pressure air. Select the filter element with intact package (if the inner package is damaged, even if the filter element is intact, it may be unclean). Clean the filter while changing the oil, and carefully clean the inner bottom of the filter housing with wiping material before installing the filter element.

Preparation before Furnace Tapping Machine Startup

Check whether there are obstacles on and around the track of the furnace tapping machine main body and plugging machine trolley. If there are obstacles, clean them immediately.

Check that all fastening bolts are fastened.

Check that all operating handles are in the stop position.

Check each oil pipe to ensure there is no damage or leakage on site.

Check whether the oil level in the oil tank is normal. When the oil level is too low, anti-wear and pressure oil must be added in time.

Check all lubricating parts and add lubricating oil.

Check whether all parts of the furnace tapping machine operate normally, and test run the trolley and oil cylinder.

CIC Heavy Mining And Cement Equipment and Service

|

Equipments |

Service |

Applications |

|

ball press machine |

ball mill installation kiln installation |

CIC fertilizer |

|

Metallurgical furnace |

sag mill design grinding mill design rotary kiln shell design mill liner design |

Metallurgy rotary kiln |

|

sludge dryer machine |

||

|

ball tube mill |

As a drilling and tapping machine manufacturer, we can provide kinds of related products for sale, and the drilling and tapping machine priceis reasonable, anything you need, please contact us.

As one of heavy equipment manufacturers, we will do our best to meet all the needs of customers.

If you want to know more kinds of sludge dryer, please visit our website.

在线联系供应商

Other supplier products

| CIC Customized and Intelligent Equipment in Minerals & Mining Processing | CIC Customized and Intelligent Equipment in Minerals & Mining Processing Mineral resources are the precious wealth endowed by nature and the m... | |

| Rod Mill | Rod mill is very similar to ball mill except for the use of steel rods as grinding media. Steel rods grind the ore by rolling and rotating in the r... | |

| Rod Mill | Rod millis very similar to ball mill except for the use of steel rods as grinding media. Steel rods grind the ore by rolling and rotating in the ro... | |

| Industrial Rotary Dryer Machine | CIC have accumulated decades of experience in the production of industrial sludge dryermachine, through continuous improvement, research and develo... | |

| Horizontal Centrifuge Machine | TWZ series horizontal vibratory centrifuge belongs to the centrifugal dewatering machine, the series of horizontal vibratory centrifuge is mainly u... |