Rolling Shutter Door Roll Forming Machine

roller shutter door forming machineIntroduction

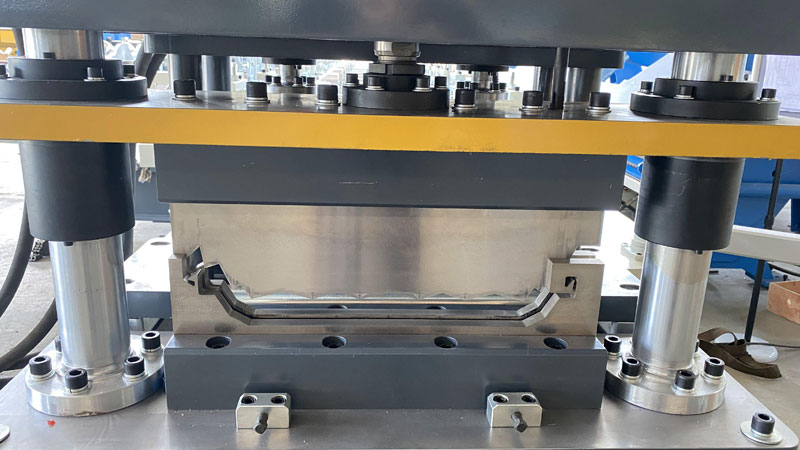

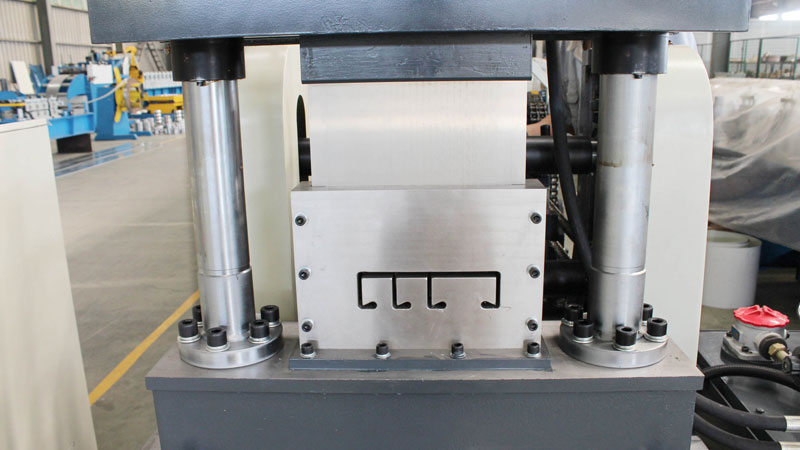

This machine is used to make various rolling shutter door panels. Our rolling shutter door machine not only forming the panels, but also has the function of punching hole and embossing. And the profile of the panels can be customized.

Rollshutter door is a multi-joint movement of the door piece in series together, in the fixed slide, with the upper part of the door scroll as the center of rotation up and down the door. Roll shutter door is usually widely used in shops, garages, and industrial buildings.

Rolling shutter door has the effect of level space like the wall, it by curtain board, seat board, guideway, support, reel, box body, control box, roll door machine, limiter, door lintel, manual speed release close device, button switch, and insurance device many parts are composed, general installation is in the place that inconvenience build wall.

Roll Shutter DoorProfile DrawingsFeatures and Advantages ofRolling Shutter Door Roll Forming Machine

Roll Shutter Door Roll Forming line, specially designed for forming a rolling shutter door panel, undermass-production.Productionspeed: 20/30/40/50/60 m/min optional.Working with a non-stop flying cutandfullautomatically stacking system, Max speed of the line can reach 60m/min.Cassette type platformquick-change Machine base formulti-profile purposesis available for choice.Certified with Multi-Patents; CECertified, EUROPEANquality standardMost of hot & popular profiles models, we have ready garage door roll formers in stock for prompt delivery.

Roll Shutter Door Roll Forming Working Flow

Coil Charging Car (optional)Decoiler (passive/auto)Front Shear(optional)Feeding and Guiding TableFilming Covering (optional)Roll Forming SystemPost-Cutting to length (Hydraulic/Motor)Output Manual Supporter/Stackmaster(optional)Rolling Shutter Door Roll

Suitable Coil Sheet Material

Suitable material: Cold/hot Rolled Steel, Galvanized Steel

Thickness: 0.8-1.3/1.0-1.6/1.5-2.0 (mm)

Yield Strength: 230-300 (MPa)

Width: as profile requests

Production Line Components and Parameters

|

5t/8t/10t/15t Motor/hydraulic motor/passive (optional) |

|

|

optional |

|

|

optional |

|

|

no need |

|

|

20/30/40/50/60 m/min (optional) |

|

|

optional |

|

|

Motor/hydraulic (optional) |

|

|

Manual supporter/ Automatic Stacker (optional) |

|

|

Stackmaster |

(Output direction) Lateral/Longitudinal (optional) |

|

Power supply for decoiler /post-cutting system |

|

|

MITSUBISH/ SIEMENSE/AMS (optional or as requested) |

Related Information

|

Machine Condition y |

Fully New, A Grade qualit |

|

Panel Shape |

As profile drawing and customer’s requirements |

|

Operator |

needed 1-2 persons |

|

Power Supply |

220V/380V/415V/460V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

About 15t |

|

Dimension |

(L*W*H) about 25*3*2m |

|

LOADING SIZE |

Normally need 1 x 40' container. |

|

Equipment Color |

Normally Blue/White, or as requests; |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Packing |

Standard and careful export packing |

Hangzhou Roll Forming Technology Co., Ltd is aprofessional rolling shutter machine manufacturerand rolling shutter machine suppliers, we provide steel coil upender, coil upender for sale, rolling shutter profile machine, rolling shutter roll forming machine, rolling shutter slats roll forming machineand etc. Want to know about roller shutter door machine price? Please contact us.

在线联系供应商

Other supplier products

| ROLL FORMING MACHINE & TUBE MILL MANUFACTURER | COLD ROLL FORMING MACHINE Cold pipe forming equipmentis to form cold plate or strip into a variety of state sectional shape of the finished steel ... | |

| Standing Seam Roll Forming Machine | Our company, Hangzhou Roll Forming Technology Co., Ltd, is a China stainless steel tube mill manufacturer and pipe mill China. This machine make st... | |

| Semi-Auto C/Z Purlin Roll Forming Machine | Semi-Automatic cz purlin machinefor Sale uses the same set of equipment to produce various specifications of C/Z purlin through semi-automatic simp... | |

| Cut To Length Line | The steel coil cut to length machine is a type of industrial equipment used to cut steel coils into flat sheets of a desired length.Hangzhou Roll F... | |

| Hydraulic Shearing Machine | 1. According to the shape of the scissors, the shearing machines are divided into straight knife shears and disc knife shears. Straight knife shear... |

Same products

| Mobile Trailer Mounted Self Priming Diesel Water Pumps | 卖方: Guangxi Dingbo Power Equipment Manufacturing Co.,Ltd | Mobile Trailer Mounted Self Priming Diesel Water Pumps water pumpare connected by Paul's qui... | |

| SCB Vertical Shaft Impact Crusher | 卖方: Jaw Crusher Equipment | SCB Vertical Shaft Impact Crusher Shanbao SCB series vertical shaft impact crusher adopts new te... | |

| PE/PEX Jaw Crusher | 卖方: Jaw Crusher Equipment | PE/PEX Jaw Crusher As a leading Jaw Crusher Supplier,Shijiazhuang Shanbao Machinery Equipment Sa... | |

| Automatic Juice and Water Filling and Sealing Machine | 卖方: Wuhan City Yijianuo Machinery Co., Ltd | Automatic Juice and Water Filling and Sealing Machine This automatic filling and sealing machine... | |

| 20T Hooklift System | 卖方: Hubei Yuantai Special Automobile Co., Ltd | Our range of hooklift productscovers a wide loading capacity, ranging from 1 ton to 30 tons, to m... |