PRESERVATION LINES Free Quote

On the preservation line, sheets and profiles are thoroughly blast cleaned and provided with a temporary corrosion protection coating. Along with the external transportation unit, the preservation lineconsists of a pass through blasting and painting machine, a painting unit and a drying tunnel with its associated slat conveyor.

Typical plates widths can vary up to 2500mm, height can vary from 5mm to 1000mm, length can vary from 2000mm to 12000mm.

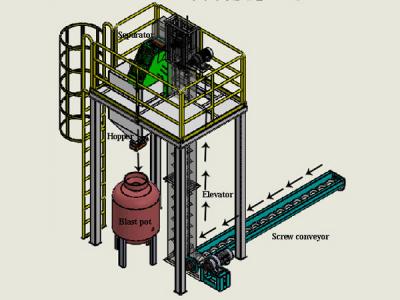

A shot blasting and priming machine usually consists of specially engineered conveyor systems, a roller conveyor shot blast machine, a pre-heater, an automatic paint spray system and a subsequent dryer. Depending on the customer requirements, different types of conveyor systems may be used, such as roller conveyors, chain or slat conveyors, cross conveyors, etc. The entire line is totally engineered around the specific application and size and geometry of the parts.

preservation line 2

preservation line 1

The roller conveyor shot blast systems are an essential part of the overall preservation line. The parts (large steel sheets, tubes and round bars, angle bars and I-beams) travel on a roller conveyor through the pre-heater chamber, the blast chamber and a blow-off/brush-off station.

The whole roller conveyor system adopts frequency control step-less speed regulation, is able to synchronous running, each department is capable of independent action.

Blast cabinet’ rollers are with special wear-resistant sleeves to prevent blasting abrasion.

Plate chain conveyor with "v" shaped structure, painted steel short-term exposure to avoid film damage.

roller conveyor

As with all roller conveyors Blast Machines the shot blasting cabinet liner is manufactured completely from high manganese. High manganese has a property which is hard enough to deal with the shot blasting from 35HRC to more than 60HRC. They are attached from the outside and are easy to replace. When aggressive shot is used, additional lining of high manganese, tool steel or cast material can be provided. To avoid shot leakage, several rubber layers or curtains are fitted in areas of heavy wear. These are mounted in a V-Track and are easy to replace.

blasting chamber

To avoid blast media building upon long parts, the rotation brushes remove the spent abrasive from the workpieces surface into a specially designed trough that has a screw conveyor taking the media back into circulation. To keep the position between the brushes and the screw conveyor constant when blasting different sized work pieces, both are built with the same adjustable framework. Finally, any remaining media on the work pieces will be removed by the blow off station, which is mounted on the same framework and uses high pressure ventilators to blow off any media remaining.

abrasive cleaning up system

2-level dust collector: settling chamber and cartridge filters. Cleaning efficiency is up to 99.5%.

Filter material from Donaldson, effective filtration area of each filter is up to 15 m³.

Air shock valve with timing device can clean filters regularly.

Economical

The cartridge dust collector is an economical choice because it requires minimal maintenance: only periodic cartridge replacement is necessary.

Fast, simple and safe cartridge replacement

Cartridge replacement is performed outside the dust collector and requires no tools. This eliminates the need to work within a confined space and allows the worker to access the cartridge without getting dirty.

After shot blasting the metal roll goes to painting booth. The painting equipment provides the coating thickness 15-20 micron.

To avoid the raw paint damage the metal roll is transferred by the chain conveyor with bearing elements. It provides minimal contact with painted surface. The paint that couldn’t reach the product is taken with air flow and directed to labyrinth filters. The filtered exhaust air is emitted to the atmosphere.

painting room of preservation line

The primer drying chamber works in recycling mode: the heated air is fed from the preliminary drying chamber with 10-15% fresh air intake from “outdoors” to prevent the recycling air oversaturation with solvents. The temperature from 30 С to 80 С is set according from primer type. As well as in painting booth, the transportation is made by chain conveyor with bearing elements. It guarantees minimal contact of painted surface with conveyor surface, protecting the painted surface from damage.

drying chamber of preservation line

- Paint blasting machine

This system has automatic explosion-proof alarm function for paint mist concentration. Adopt advanced cardboard to filter paint mist, it is maintenance-free within one year, using activated carbon for adsorption of harmful gases. After this system it will be in accordance with the air pollution emission standards. (Paint mist emission standard ≤ 120mg/M3, p-xylene: emissions concentrations ≤ 70mg/M3, the 15 meters height exhaust pipe allows the secondary emission rate is 1.0kg/h. )

QINGGONG MACHINERY is a professional shot blasting manufacturer, we provide shot blasting machine, blast pro shot blasterand etc. Want to know blasting media comparison or more? Please contact us.

在线联系供应商

Other supplier products

| GAS CYLINDER SHOT BLASTING MACHINE | Gas cylinder shot blasting machine is used to automatically clean the surface of the cylinders by blasting of the abrasive coming from the blast tu... | |

| Sandblasting Room | The sandblasting roomdesigned by QINGGONG Machinery can complete a wide range of blasting jobs for those big and irregular workpieces. Traditional ... | |

| PAVERS SHOT BLASTING MACHINE | Paver shot blasting machine is mainly used for surface roughening treatment of marbles, granites, concrete products, and natural stone. It includes... | |

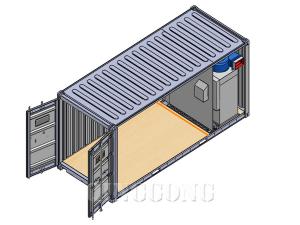

| TRANSPORTABLE CONTAINER BLAST ROOM | The movable sandblasting room or portable blast room, abrasive recovery system, dust collector, portable shot blasting machinetogether, it can be t... | |

| STEEL PLATE SHOT BLASTING MACHINE | Steel plate shot blasting machine is one kind of roller conveyor shot blasting machines. It can remove all rust, corrosion and mill scale from stee... |

Same products

| 12V 250AH Gel Battery for Solar system | 卖方: Shenzhen Changing Technology Co., Ltd | 12V 250AH Gel Battery for Solar system The 12V 250Ah Gel Batteryis a high-performance, maintenan... | |

| 39/52/65kW 61.44kWh Small-Scale C&L Energy Storage System | 卖方: Shenzhen Changing Technology Co., Ltd | 39/52/65kW 61.44kWh Small-Scale C&L Energy Storage System ICHES-B is a high-voltage energy s... | |

| 24V 60Ah Lithium-ion Battery for Golf Cart | 卖方: Shenzhen Changing Technology Co., Ltd | 24V 60Ah Lithium-ion Battery for Golf Cart The UT-GC2 Series 24V 60Ah Golf Cart Lithium-ion Batt... | |

| The 332.8V 10kWh (Single Phase) | 卖方: Shenzhen Changing Technology Co., Ltd | The 332.8V 10kWh (Single Phase) Residential Energy Storage Systemis a high-capacity, premium-grad... | |

| 220/230/240V 5kWh - Residential Energy Storage System | 卖方: Shenzhen Changing Technology Co., Ltd | 220/230/240V 5kWh - Residential Energy Storage System The 220/230/240V 5kWh Residential Energy S... |