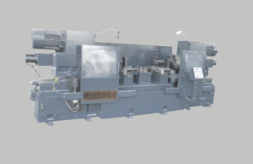

303E-3-S OEM Hydraulic Busbar bending/punching/shearing machine for copper

303E-3-S OEM Hydraulic Busbar bending/punching/shearing machine for copper

1、Introduction

The machine is equipped with punching cutting bending three units,the three units can work at the same time,and will not influence each other.The punching unit is turret structure,the bending unit is closed on the top,the bending Angle is with storage function.The main function is processing different types of copper(brass) aluminum bus bar.when it is working,worker just need to choose the unit,then machine will cutting and punching(holes,long holes square holes special holes),horizonal bending,vertical bending embossing flatting torsional Hemp flowers ect.

2.Main Characteristic:

★SIEMENS 40 PLC control system from German, which is with Automatic shutdown function,and can control the down time of cutting unit and punching unit,it is more stable and reliable than traditional relays.

1.Punching unit is with nodular-cast-ironed and turrent typed turntable with 4/6/8 molds holes,which is a who one,so that the holes for molds(the molds is processed by our processing center) with higher precision and the clearance of the molds and turntable is 0.00-0.03mm,improving the concentricity,then the life of molds can be longer and need not change the molds so frequent.

By added punching position,the machine can locate x axis and y axis mechanical double direction location. that makes workers need not to cross lines and make punching marks , then improving the operating efficiency and accuracy of punching.

2、Cutting unit is with double upright pillars and double blades cutting structure(Patent NO.ZL.1) the above blade and below blade are installated vertically parallelly ,make sure the cut smooth,no waste,no deformationfor longtime used.

3、Bending unit is with closed bendin,output point and force bearing force are connecting with beam of 50mm thickness,the mechanical strength is stronger than those open bendin.

4、Bending Angel is controlled by Numerical control system.Z bending can be processed through enter H (vertical height of above and below planes)and L(length of Hypotenuse) (it can calculate the angel that needed itself).When it is working ,Workers just need enter the angel and the thickness for the busbar that needed then the machine can processing the parts conviently and fast.And the machine is with storage function and erro compensation.

6、Bending unit can processing U bending.the minum distanceis 40mm

7、SIEMENS 40 PLC control system from German, which is with Automatic shutdown function,and can control the down time of cutting unit and punching unit,it is more stable and reliable than traditional relays。

8、Hydraulic oil tank is welded by 3mm thickness steel plate,and with phosphating,making the hydraulic oil can be used longer and will not be deterioration.

9、The machine offers the oil one to one,three cylinders/three pumps,not influence each other.

10、Cylinder oil tubes are with international A type connection,durable and easy to repair.

11、The machine is with casters,easy to move.

3.Main parts:

1、 Main Motor Juliweite 3

2、 Hydraulic Oil Cylinder LIJIAN (MADE IN TAIWAN) 3

3、 Electromagnetic reversing valve FENGYI 3

4、 Electromagnetic relief valve FENGYI 3

5、 AC contactor SIEMENS 3

6、 Thermal relay SIEMENS 3

7、 PLC SIEMENS 1

8、 encoder GUANGYU 1

9、 Touch screen Taiwan PlanelMaster 1

4.Random Annex:

punching molds 8sets(Φ7、Φ9、Φ11、Φ13、Φ17、Φ11×15、Φ13×17、Φ17×21)、Scissors 1set、horization bending molds 2sets(total 3)、vertical bending molds 2sets(total3)、embossing molds 1set、random repair tool 1、the standby seal ring 1bag、foot switch3。

5.Parameter:

1、Nominal pressure 300KN

2、Max size for cutting 12×160mm

3、Size of punching Φ4.3~25mm

4、Max size of horizontal bending 12×160mm

5、Max size of vertical bending 12×120mm

6、Max size of work bench 1500mm×1200mm/940mm×420mm

7、Size of the machine 1750mm×1350mm×1500mm

8、Weight of the machine 1390kg

Contact informaition:

Tel:

Web:

在线联系供应商

Other supplier products

| QT6-15B Concrete Brick Paver & Curbstone Production Line | QT6-15B Concrete Brick Paver & Curbstone Production Line Concrete brick Concrete Brick Production Line Paver & Curbstone Production Line Pa... | |

| Takeup payoff rewinding line for cables | Takeup payoff rewinding line for cables Technical Specifications of Rewinding Line The rewinding line includes two stands, each with the function o... | |

| RA-XK214 high-precision Gantry CNC milling machine | RA-XK214 high-precision Gantry CNC milling machine CNC milling machine Gantry milling Gantry CNC milling machine high-precision Gantry CNC milling ... | |

| RA-DT103 Horizontal double-sided combination boring machine | RA-DT103 Horizontal double-sided combination boring machine Henan Beshine International Limited located in Luoyang, an ancient capital of China, w... | |

| RA-ZK218 Horizontal CNC drilling and tapping machine | RA-ZK218 Horizontal CNC drilling and tapping machine drilling and tapping machine CNC drilling and tapping CNC drilling and tapping machine Horizon... |

Same products

| XD-MAX Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |