Laser cutting machine for metal cutting

Product description:

The exchange platform tube and tube dual-purpose fiber laser cutting machine realizes cutting of two different materials on the same machine. The plate and tube dual-purpose fiber laser cutting machine adopts cast iron bed, rack and pinion transmission system, professional cutting tube numerical control system, easy to use, simple operation and maintenance. At the same time, the rigorous assembly process ensures high-precision and stable operation of the machine. The use of imported high-end accessories greatly improves the cutting accuracy and efficiency, and is an ideal choice for economical user tube processing.

| Parameters: | |||

| Model | EK-ET3015 | EK-ET4020 | EK-ET6020 |

| Working area | 3000*1500mm | 4000*2000mm | 6000*2000mm |

| Maximum moving speed | 120m/min | ||

| Maximum acceleration | 1.3G | ||

|

positioning accuracy

|

0.5mm | ||

|

Repeatability

|

±0.03mm | ||

| Laser power | 1000w/1500w/2000w/3000w/4000w | ||

Exchange platform:

The machine is equipped with an exchange double table that can load and unload sheet metal parts during the cutting process. The workbench is equipped with a rotatable ball-type support to facilitate the movement of the plate. It is equipped with a positioning device and a clamp to vertically position the plate to prevent the plate from moving, to ensure the machining accuracy of the parts and to reduce waste. Automatic exchange platform, the equipment can be loaded and unloaded during the processing, the loading time is only 10s, which greatly shortens the working time and improves the working efficiency.

| Metal pipelaser cutting machine: | |

| 1 | High cutting precision, smooth cutting, clean, no burr, low material loss; |

| 2 | The heat-affected zone of laser cutting is small and there is almost no thermal deformation. |

| 3 | Mass production, high efficiency cutting. The standard pipe length is 6 meters. Conventional machining methods require very large fixtures, and laser machining can easily complete the positioning of several meters of pipe clamps, which makes batch processing possible. |

| 4 |

The laser cutting machine is controlled by a digital system and is one of the advantages of laser cutting machines for cutting pipes. Laser-cut tubing technology can handle any programmed shape and can be cut in any direction, enabling a wide variety of cutting processes for complex tube structures such as cutting, chamfering, grooving or perforating, scoring and more.

|

| Cast iron bed: Fiber laser cutting machinehave very high machine stability requirements, and high precision and high stability machine tools help to improve the precision of laser cutting. The cast iron bed used in this machine has the following characteristics. |

|

| 1 | The cast bed is made of gray cast iron, which has high carbon content and is not easily deformed by heat. |

| 2 | Casting bed body, integrated molding, after aging treatment, its internal stress is almost negligible, so the stability is extremely high, which can keep the precision of the machine tool for a long time. |

| 3 | Compared with the ordinary welded bed, the cast bed is much heavier and the machine vibration is small, so that the machine tool reduces the influence from other reasons and improves the cutting precision. |

| 4 | The deformation of the casting bed is less sensitive. Because the bed is in the process of transportation and processing, there will be an inevitable accidental gap. Due to the material characteristics, the cast iron bed will not cause any change due to the gap, thus further improving the comprehensiveness of the machine tool. stability. |

Cast aluminum beam:

It is manufactured using aerospace standards and extruded using a 4,300 ton press. After aging treatment, the hardness can reach T6, which is the highest hardness of all beams. Aerospace aluminum has a high enough performance index, its strength, plasticity, impact toughness, fatigue performance and weldability are very good, more importantly, the cast aluminum beam has a lighter weight under the premise of ensuring the same performance index. It is convenient for high-speed movement during cutting and processing, and realizes rapid cutting of various types of graphics while satisfying accuracy.

Fiber laser cuttersample:

Fiber laser cuttersample:

Shandong EAAK Machinery Co., Ltd

在线联系供应商

Other supplier products

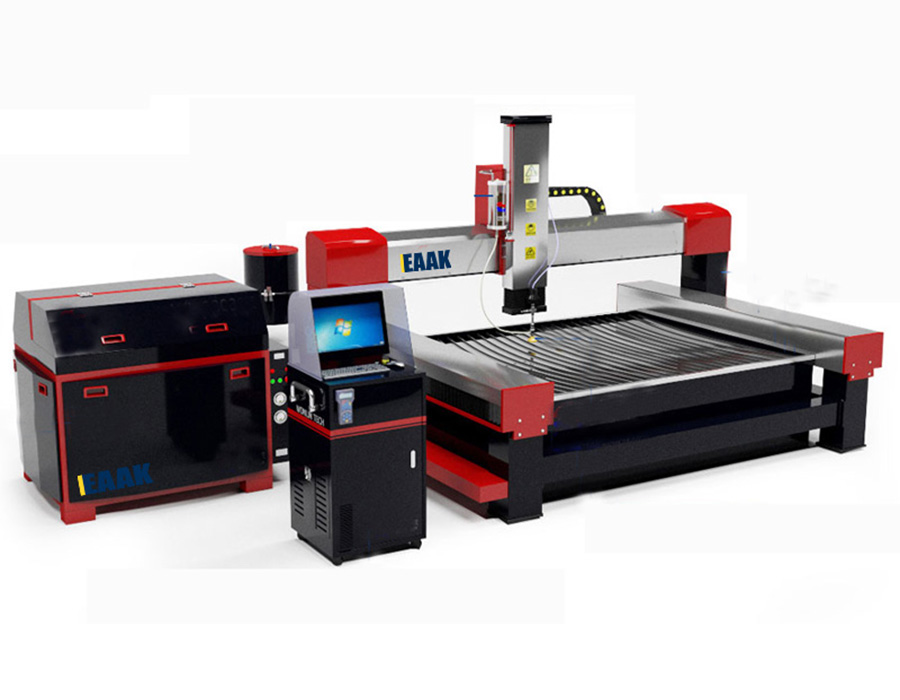

| high pressure abrasive water jet cutting machine for metal glass stone | EAAK water jet cutting machine application:Can be used to cut almostly all the materials such as stainless steel,carbon steel,copper,brass,aluminum... | |

| small water jet cutting machine for metal glass stone | EAAK water jet cutting machine application:Can be used to cut almostly all the materials such as stainless steel,carbon steel,copper,brass,aluminum... | |

| waterjet cutting machine and cnc waterjet cutter | EAAK water jet cutter application: Cutting materials are not limited (stainless steel, steel, copper, aluminum and other metals, glass steel, stone... | |

| High pressure waterjet machine for metal cutting | EAAK new design water jet cutting machine EK1020N is with compelte new color and new structure design, can save more space and works steady.Specifi... | |

| Гидроабразивный станок | Specification of EAAK CNCwater jet cuttingmachine:(as follows) Model EK3020 X Y axis Working size 3000mm*2000mm Z working height 150mm Cut... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | 卖方: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |