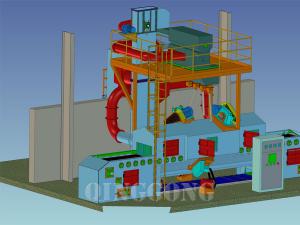

MESH BELT SHOT BLASTING MACHINE

Wire mesh shot blasting machineor steel belt shot blasting machineis suitable for continuous blasting thin and collision-sensitive die castings, pressure castings, ferrous and non-ferrous castings, forgings, automotive accessories, and weldments. Workpiece weight ranging from 1kg to 100kg. A highly wear-resistant wire mesh belt, with tension adjustment, provides the part transport. Wire mesh belt width has 600mm, 800mm, 1000mm and 1200mm.

Mesh Belt Shot Blasting Machine Basic Specification

|

MACHINE TYPE |

QGM-600 |

QGM-800 |

QGM-1000 |

QGM-1250 |

QGM-1500 |

|

600x400 |

800x400 |

1000x400 |

1250x400 |

1500x400 |

|

|

wheels Number x power(kW) |

4x11 |

4x11 |

4x11 |

4x15 |

4x15 |

|

Alternative wheels Number x power(kW) |

4x15 |

4x15 |

4x15 |

6x11 |

|

|

Foundation pit |

no |

no |

no |

yes |

yes |

Working process

Treated objects are placed on horizontal network conveyor going through the shot blasting machine. In the process of shot blasting the treated objects move through jets of shot blasting agent from turbines, which are installed at different angles with regard to the direction of the movement which provides efficient treatment.

The machine's housing is protected by wear-resistant manganese steel. High efficiency of the machine is enabled by the system for continued returning and cleaning of the shot blasting agent, along with efficient shot blasting turbines made from wear-resistant materials. The shot blasting machine's size, number, and power of shot blasting turbines, length of network rail conveyor on the treated object's loading and unloading site, the capacity of the conveyor and frequency regulation of turbine's revolutions are done in accordance with the needs and specifications of the buyer.

mesh belt shot blasting machine 2

Mesh belt shot blasting machine advantage:

Shot Blasting Machine

QINGGONG MACHINERY shot blasting machineoffers you an effective solution to deal with the surface of the workpieces, including remove the contaminant on the surface, clean and roughen a smooth surface before applying a primer or coating to the workpiece. More specifically, the treatment of a shot blasting machine includes derusting, descaling, desanding, or deburring of the workpieces. Other uses are such as surfaces shot peening, finishing and roughening of surfaces so as to make coat better.

在线联系供应商

Other supplier products

| H Beam Shot Blasting Machine | QINGGONG MACHINERY shot blasting machineoffers you an effective solution to deal with the surface of the workpieces, including remove the contamina... | |

| ROTARY TABLE SHOT BLASTING MACHINE | Rotary Table Shot Blasting Machine for Sale Rotary shot blasting machineor table type shot blasting machineis suitable for various shapes and dime... | |

| MECHANICAL CNC TURRET PUNCHING PRESS MACHINE | Closed mechanical CNC turret press machineby the programming software (or manual) processing program, by the servo feeding mechanism sent the plate... | |

| GAS CYLINDER SHOT BLASTING MACHINE | Gas cylinder shot blasting machineis used to automatically clean the surface of the cylinders by blasting of the abrasive coming from the blast tu... | |

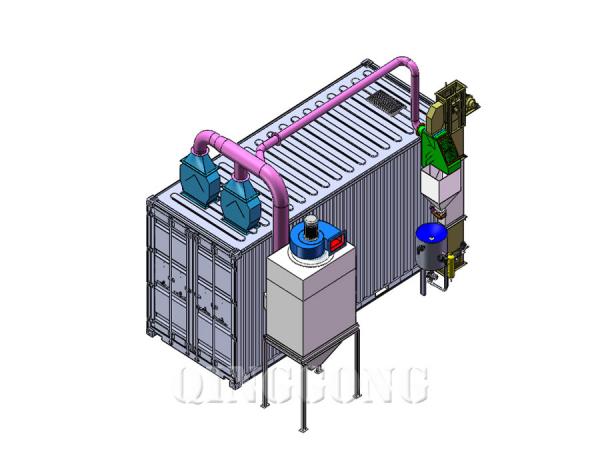

| CONTAINER BLASTING ROOM | When factory space is at a premium or a temporary site is to be utilized our shot blasting containerprovide an instant and economical solution. Con... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | 卖方: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |