Cold Forging Bushing Sleeves

Basic Info.

Trade Term: EXW,FOB,CIF.CFR

Payment Term: T/T,L/C, Western Union

Delivery Time:7-30days

Place of Origin: Ningbo, China

Information About HEWCHO Cold Forging Bushing Sleeves

Features of cold forging sleeves:

·Product name: Cold Forging Sleeve Bushing

·Material: Carbon Steel, Stainless Steel, Aluminum, Brass

·Machining Tolerances:0.01mm

·Machining Process:

Cold Forging, CNC Turning, CNC Milling, Grinding, Threading, Tapping, Bending, Welding, Drilling, Forging

·Min. Order:50,000PCS

·Surface Treatment: Polishing, Heat Treatment, Sand Blasting, Zinc Plated, Anodization, Chemical Fim,

·Packing: Carton Box, Blister tray, Pallet, Wooden Case.

·Certificate:ISO9001:2008, ISO/TS16949

|

WhatwecanProvide: |

MachiningMaterial: |

||

|

CNCMachiningService |

CarbonSteel |

||

|

CNCTurningService |

StainlessSteel |

||

|

CNCMillingService |

Aluminum |

||

|

ColdForgingService |

Brass |

||

|

MetalStampingService |

Copper |

||

|

TitaniumAlloy |

|||

|

SurfaceTreatment |

Application: |

||

|

HeatTreatment |

AutomobileSpareParts |

||

|

SandBlasting |

ElectricalApplianceIndustry |

||

|

Polishing |

ElectronicsIndustry |

||

|

ZincPlated |

GeneralIndustry |

||

|

Anodization |

MachineryandEquipment |

||

|

ChemicalFim |

HydraulicandPneumatic |

The bushing and sleeve is used for the outside of the mechanical parts, in order to achieve the sealing, wear protection and other functions of the match, refers to the role of the liner ring.

In the moving parts, wear of the parts is caused by long-term friction. When the gap between the shaft and the holes wears to a certain degree, the parts must be replaced. We choose the material with low hardness and good abrasion resistance as the sleeve or liner. The sleeve, which can reduce the wear of the shaft and the seat, can be replaced when the sleeve or bush wears to a certain degree, so that the cost for replacing the shaft or the seat can be saved.

The function of bushings

The flexibility of the bushing is relatively high, and it has many functions. In general, the bushing is a type of component that protects the equipment. The use of bushings can reduce equipment wear, vibration and noise, and have anti-corrosion effects. The use of bushings also facilitates the maintenance of mechanical equipment and simplifies the structure and manufacturing process of the equipment.

Bushing Features

Small deformation, high precision; good concentricity; good verticality; high wear resistance.

Application of Cold Forging Bushing Sleeves

Used in: packaging machinery, textile machinery, mining machinery, metallurgical machinery, printing machinery, tobacco machinery, forging machinery, various types of machine tools and interchangeable mechanical drive linkage. For example: pulleys, sprockets, gears, propellers, large fans, and other types of couplings, etc.; Features: Large torque, high accuracy, quick and easy assembly and disassembly, easy operation, good positioning, reduced scrapping rate of the shaft and hub being engaged, Reusable, no damage to the mating surface, is the best and most economical choice.

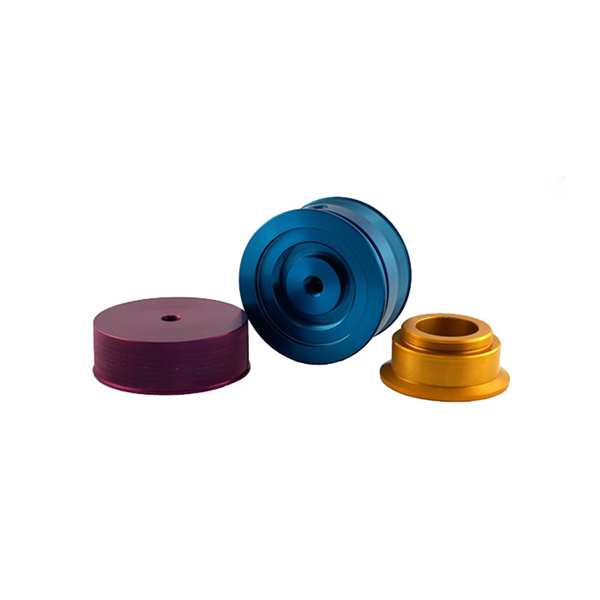

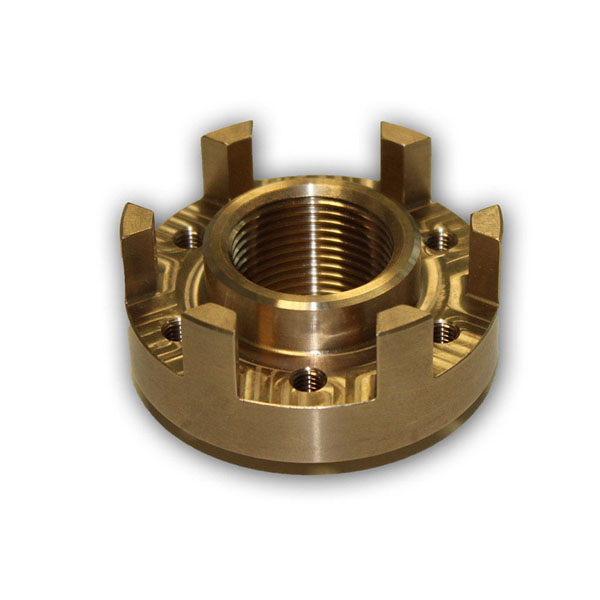

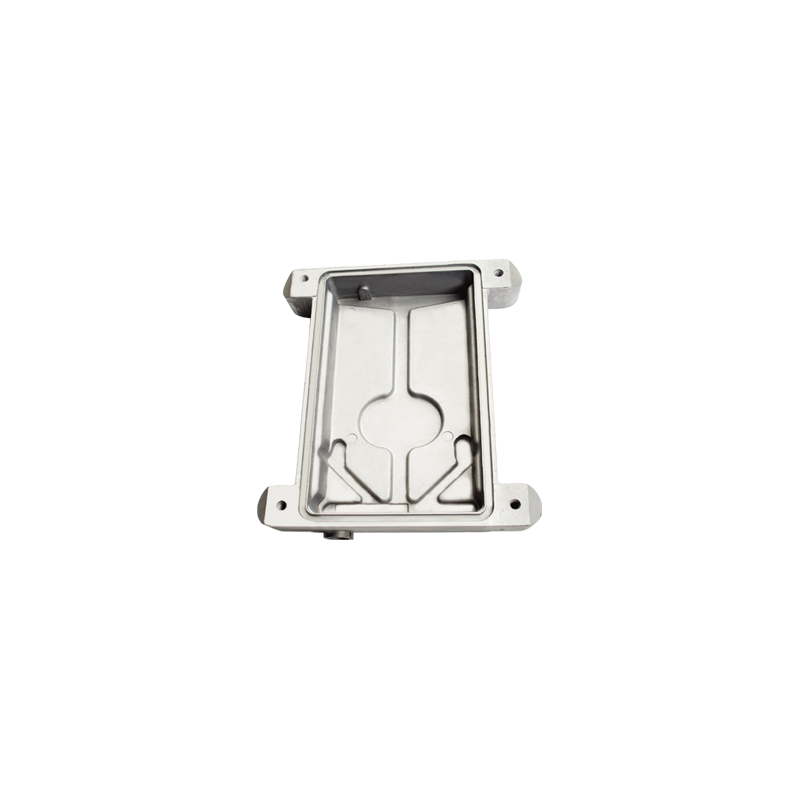

Gallery

Ningbo Hewcho cold forging companiesspecialize produce customized non-standard cold forging sleeves and bushings.

Machining Tolerances

According to custom requirement. Normally the diameters tolerance is ± 0.01mm.Length tolerance is ±0.5mm.But in many cases, we can achieve: diameters tolerance is ±0.005mm.Length tolerance is ±0.02mm

Material Selection:

Normally used carbon steel 35# or 45# ,Stainless Steel:304 or 316.According to customer requirement use Aluminum and Brass

Surface Treatment:

Heat treatment, Polishing, Zinc Plated, Zinc-Nickel Alloy Plated, Chrome Plated

Ningbo Hewcho turned parts manufactureris an ISO:9001 and ISO/TS16949 certified company dedicated to manufacturing superior-quality Precision CNC machined parts and custom metal components to customer specifications. With a strong focus on continual improvement, our company only utilizes best-practices to ensure that the work we do for our customers is done in the most efficient, precise and cost-effective way possible.

在线联系供应商

Other supplier products

| Cold Forging Flange Parts | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Information Abo... | |

| Aluminum CNC Machining Parts | CNCParts for Sale Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo,... | |

| Alloy Steel CNC Machining Parts | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Features of All... | |

| Brass CNC Milling Parts | Basic Info. Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Features of bra... | |

| Carbon Steel CNC Milling Parts | Trade Term: EXW,FOB,CIF.CFR Payment Term: T/T,L/C, Western Union Delivery Time:7-30days Place of Origin: Ningbo, China Carbon Steel CNC Milling Par... |

Same products

| industrial sewing machine spares | 卖方: Zhejiang Huaqi Information Technology Co., LTD | Our spares are made from robust materials that can withstand the rigors of continuous use in indu... | |

| Flat End Type of Thread EndSuction Machine | 卖方: 千实精密机电仪器检测设备有限公司 | TRANSLATE with x English Arabic Hebrew Polish Bulgarian Hindi ... | |

| Fabric Friction Electric Charge Density Tester | 卖方: 千实精密机电仪器检测设备有限公司 | TRANSLATE with x English Arabic Hebrew Polish Bulgarian Hindi ... | |

| Mask Air Exchange Pressure Difference Tester | 卖方: 千实精密机电仪器检测设备有限公司 | TRANSLATE with x English Arabic Hebrew Polish Bulgarian Hindi ... | |

| Face Mask Tensile Testing Machine | 卖方: 千实精密机电仪器检测设备有限公司 | TRANSLATE with x English Arabic Hebrew Polish Bulgarian Hindi ... |