Auto Duct Production Line 4

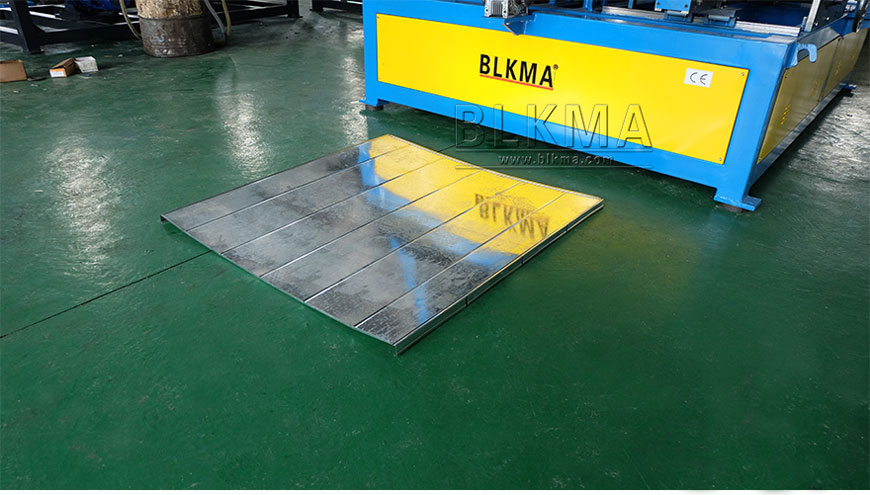

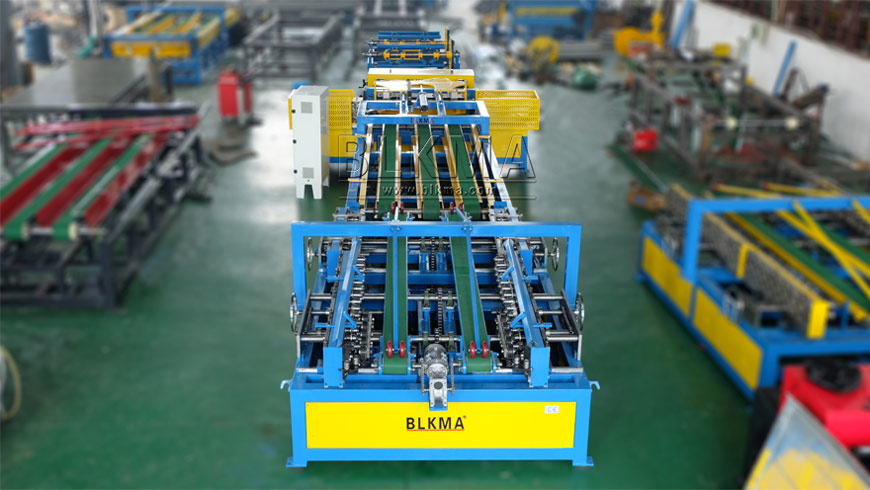

It's mainly for uncoiling, leveling, beading, punching, locking, bilaterally angle steel or TDF flange forming. Because of its small space requirement and easy to install and operate, people also call it "small line 5".

Auto Duct Production Line 4 Performance Features:

The function of auto duct production line 4 mainly includes unwind, leveling, beading, notching, locking and flange forming. The main machine of auto duct line 4 is used to level, bead, notch, and shear. All the rolling reels are made of bearing steel so that the lifetime will be prolonged. The injection holes are used on both sides of the drive shaft to enhance the bearing life. There is the material-saving mode. The machine can withdraw sheet metal automatically. Besides, the auto duct line 4 machine has the production record function. The operator can check production order. The imported configuration includes Germany Festo cylinder, Bejing Huade and Taiwan hydraulic system, Taiwan Hiwin linear guideways and Schneider electric system. Cnc system is Japan Mitsubishi. Meanwhile, the basic configuration includes two electric material racks (4 material trays, 5-7T each roll), one rack, one main machine (line 2 host), one mechanical arm for clutching, locating and transferring, one lock forming machine, one duplex TDF flange forming machine, one duplex angle steel flange forming machine and a set of computer controlling system. The operator can use the auto duct line 4 machine with other square duct machines, for example, hydraulic/pneumatic/manual folding machine, hydraulic/pneumatic/electric lock seam closing machine, corner punching machine, corner assembly machine and so on together to complete the whole duct. The line 4 machine can make max sheet thickness 1.2 mm. For sheet width, there are two models that can be chosen, max width 1300 mm or max width 1500 mm. Our company can provide customers different choice according to different requirements. You can contact us at any time you want via , mob, WhatsApp, Skype, facebook, youtube and question about HVAC duct manufacturing machines. Besides, we can provide engineer overseas service if customers need.

Auto Duct Production Line 4 Main import Configuration:

|

Cylinder imported from Germany Festo |

|

Mitsubishi CNC control system |

|

Japan Omron encoder |

|

Taiwan Hiwin linear guideways |

|

Schneider electrical system |

Auto Duct Production Line 4 Basic Configuration:

|

Twoelectric coil cradles, 4 material trays (5-7t each roll) |

|

One rack |

|

One host (line 3 host) |

|

One mechanical arm clutching, locating and transferring platform |

|

One displacement type locking machine |

|

One duplex TDF flange forming machine |

|

One duplex angle steel flange forming machine |

|

One set of computer controlling system |

Auto Duct Production Line 4 Main Technical Parameters:

|

Model |

Sheeting thickness (mm) |

Max width (mm) |

Max working speed (m/min) |

Max weightof coil (T) |

Dimension (mm) L*W*H |

Power (kW) |

Weight (T) |

||

|

ADL-4-1300 |

1300 |

15 |

7 |

18000 |

3500 |

1500 |

26 |

9 |

|

|

ADL-4-1500 |

1500 |

15 |

7 |

18000 |

4000 |

1500 |

26 |

10 |

|

We have heavy industrial machinery,spiral tubeformer,cnc duct fabrication machine,air duct fabrication machines,hvac duct fabrication equipment,duct manufacturing equipment,ductwork fabrication equipment,duct fabrication equipment,ductwork equipmentand hvac duct machine.RFQ today.

在线联系供应商

Other supplier products

| Pneumatic Lock Seam Machine | Pneumatic Lock Seam MachinePerformance Feature: Pneumatic lock seaming machine is the convenient one which can be used to lock max length 1250 mm ... | |

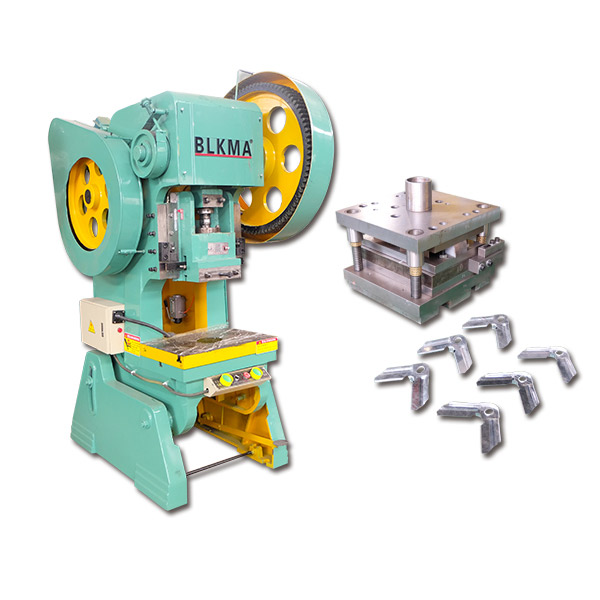

| Duct Corner Punching Machine 2019 | Duct Corner Punching Machine Performance Features: Model Pressure(KN) Dimension of die holder(mm) Slider stroke Slider stroke times P... | |

| Auto Duct Production Line 2 | Duct production line 2 can drive blanking for duct and TDF flange forming machine at the same time.Combined with TDF flange forming machine, rollin... | |

| Lock Forming Machine | Locking machine is necessary in duct area because it can produce all kinds of types to meet locking requirements. Standard machine can process 0.5-... | |

| Electric Rolling Machine | Pre-bending function makes straight edges narrower, and it can even round small round pipe with diameter of 100mm. Combined with manual worm gear a... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | 卖方: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |