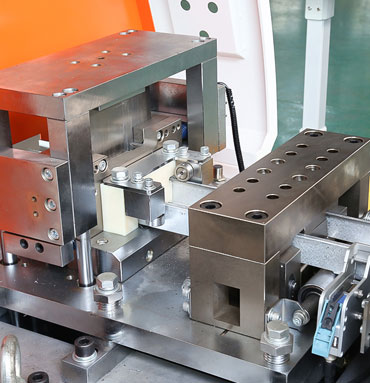

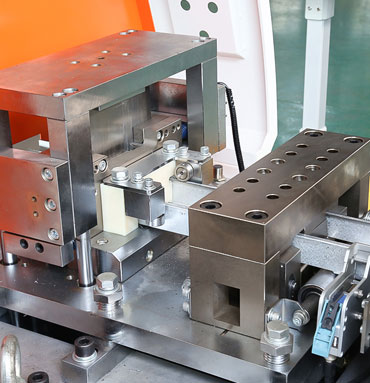

PROFILE ROLL FORMING MACHINE

The steel profile roll forming machinemainly consists of four parts:

The first is the input section - in this section, the material is loaded at a continuous rate.

The next part is the roller section - in this part of the machine the material will change in the desired shape. For this purpose, any belt will be made by different sets of rolls.

The third part of the machine is roll forming - in this part the metal will be cut to a fixed length. The cutting process will run at the speed at which the machine is running.

The last part of the machine is the exit section - when the entire process is completed, the required metal will pass through that section.

Working ofProfile Roll Forming Machine

The steel profile roll forming machine forms the metal at room temperature. The drum of the machine contains a number of parts for tying the metal. Once the metal strip passes through a section, the metal is transferred to the section by a roller. Each part of the drum creates more belts in the metal. This process will continue more times to achieve the desired metal shape. Steel profile roll forming machines are suitable for the manufacture and processing of large and wide parts.

Tolerance ofProfile Roll Forming Machine

The various parts produced by the steel profile roll forming machine are based on the equipment, the materials used and the application process. The tolerance of the machine can be changed by changing the thickness of the metal in the production process.

Advantages ofProfile Roll Forming Machine

We can judge whether the machine is beneficial by measuring the energy consumed by the machine. The main advantage of steel profile roll forming travel is that it is used to form metal at room temperature. Therefore, due to this function, this is an energy saving machine.

In addition, roll forming travel has an adaptable, modifiable process and flexible duration. It provides reliable and correct results.

BOSJ is a professional china roll forming machine manufacturer. We provide Roll Forming Machine, Tube Welding Machine, china roll formerand so on. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| CEILING ROLL FORMING MACHINE | Ceiling roll forming machineis a special machine designed for the ceiling industry. It has high speed and high efficiency, stable performance, low ... | |

| PANEL ROLL FORMING MACHINE | Overview of Panel Roll Forming Machine The color plate produced by discharging, forming and post-forming cutting has a flat appearance, uniform pai... | |

| ALUMINIUM ROLL FORMING MACHINE | How to Prevent Rust Treatment of Aluminum Profile Cold Forming Machine The gear oil used in the machine tool of the aluminum profile china cold ... | |

| Panel Roll Forming Machine | In the BOSJ Plant, you will get an exciting look behind the scenes of china cold roll forming machineparts manufacturing and installation. The tour... | |

| PROFILE ROLL FORMING MACHINE | The steel profile roll forming machinemainly consists of four parts: The first is the input section - in this section, the material is loaded at... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | 卖方: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |