Garri Processing Machinery

Cassava Garri(Gari) Process Description and Flowchart:

Garri is a fermented and gelatinized dry coarse flour, very popular in West Africa and a staple food in Nigeria, Ghana, Benin, and Togo. Its ability to store well and its acceptance as a "convenience food" is responsible for its increasing popularity in the urban areas of West and Central Africa. It is often consumed as the main meal in the

form of a dough or a thin porridge. Both are prepared in the household by mixing dry Garri with hot or cold water and cooking and are served with soup or stew. Garri is also eaten as a snack when mixed in cold water with sugar, and sometimes milk. It swells three to four times its volume when mixed with cold water.

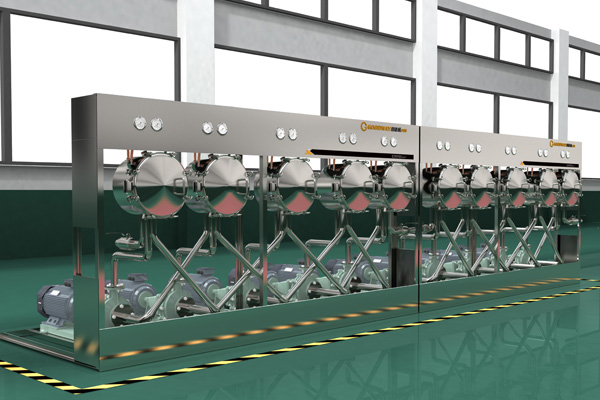

Goodway delivers the whole range of garri processing equipmentindustry from Garri processing machinery to complete the gari processing machinesline. Multiple distinct operations are required in Garri processing: washing, peeling, grating, de-watering, breaking & sifting, Garri roasting, milling, and packaging.

We provide below a brief description of the main steps of the Garri(gari) production process.

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It's the first step of Garri(gari) process and very important for the quality of final Ggarri(gari).

Peeling Cassava Roots

Peel the washed cassava roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

Grating Peeled Cassava Roots into Mash

Load the grater with washed roots while the engine is running to grate peeled cassava roots into mash. The grating drum and all food contact areas should be made

from stainless steel.

Fermenting Mash on the Fermentation Rack

Collect the cassava slurry into a clean polythene sack and tie, then bagged cassava slurry can be left in the fermentation rack for one or more days before de-watering, allow the milky water to drain freely from the bags.

De-watering Mash into Wet Cake

Load the bags directly on to a hydraulic press. Lift and press the jack handle up and down until it becomes hard to move. Repeat the process several times each day until no more water comes out of the bag to produce a firm wet cake.

Breaking Wet Cake and Sifting Wet Cake into Grits

Breaking the wet cake into small pieces (grits) and remove the lumps to obtain uniform size grits(wet coarse Garri). All food contact areas should be made from stainless steel

Roasting Grits into Dried Coarse Garri(Gari)

Roasting the wet grits into dried coarse Garri(gari) with low moisture content using an automated Garri fryer made of stainless steel material and with electricity, natural gas, firewood or charcoal as the heat source. The final Garri(gari) is usually recognized from the color of palm oil fortified Garri or non-palm oil fortified Garri and crispy hand feel of particles.

Milling Coarse Garri into Fine Garri(Gari)

Milling the dried coarse Garri into fine Garri(gari) with the uniform size, then pour the fine Garri into a plastic lining inside a woven polythene sack.

We provide different Garri ProcessingMachinetypes, such as garri making machine, garri machine, cassava garri processing machines.

在线联系供应商

Other supplier products

| Potato Starch Making Machine | Features of Potato Starch Making Machine Potato Starch Making Machine Potato Starch Process Description and Flowchart: Goodway has been contin... | |

| Garri Fryer(Cassava Garri Fryer) | Features of Garri Fryer(Cassava Garri Fryer) Roasting be done mechanically using an automated garri fryer made of stainless steel material and wi... | |

| Garri Fryer(Cassava Garri Fryer) 2019 | Features of Garri Fryer(Cassava Garri Fryer) Roasting be done mechanically using an automated garri fryer made of stainless steel material and with... | |

| Sweet Potato Starch Machine | potato starch machinesweet potato starch machine Features of Sweet Potato Starch Machine Sweet Potato Starch Machine Sweet Potato Starch Process ... | |

| Cassava Stone Cleaning Machine | Features of Cassava Stone Cleaning Machine Used to remove the stones in the material such as rigid particles of impurities, at the same time have a... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | 卖方: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |