Roll Forming Machine

In the BOSJ Plant, you will get an exciting look behind the scenes of china cold roll forming machineparts manufacturing and installation. The tour of BOSJ Group parent plant takes you through all production areas from the press works to assembly. The main plant is located in the Yangtze River, near Shanghai. Approximately 150 employees work with BOSJ.

HIGH-QUALITY ROLL FORMING MACHINE FOR YOU

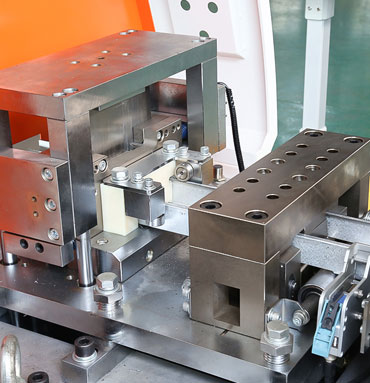

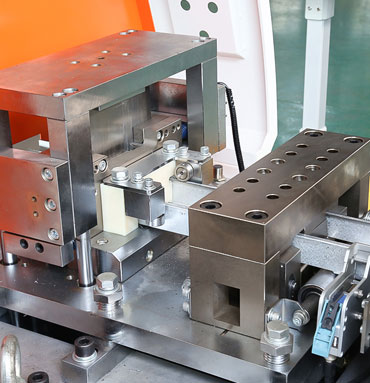

Roll Design and Manufacturing Features of Automatic Cold Roll Forming Machine:

Each roller power for each roller is average, total production line is stressed, the wear is balanced, and the service life of the roll is extended.

Roller material good material is to use its wear resistance, but the specific strength and hardness are contradictory, the red hardness should be utilized during heat treatment, and the hardness can be achieved after two or even three times of tempering after quenching.

The arc part of the track is the core part of the slide rail. The arc position of the first few passes after the press forming, in the subsequent pass rolling the vertical edge, the formed arc should be formed, and the effective tube bundle protection is carried out by the upper and lower rolls or the horizontal wheel.

Otherwise, the arc position of the material will change during the stretching process, R becomes smaller and becomes a triangle, the steel ball is not in the end, the two points contact the noise, and when the R becomes large, the coordination rail is swayed, and the track is blurred when used. Uneven force, deformation of the slide rail and shortened life.

How to solve the stability problem when using the roll forming equipment?

Rolling stability problem, the production often encounters the problem of material yaw in the raceway, in fact, the single set of rollers is asymmetrical, the left side is strong, the material is yaw to the right; the right side is strong, the material Deflection to the left.

There are quality roll forming machine for sale, such as uprightrollformingmachine, corrugated roll former for sale, etc. We also provide a competitive pop channel machine pricefor customers.

在线联系供应商

Other supplier products

| Profile Roll Forming Machine | In the BOSJ Plant, you will get an exciting look behind the scenes of china cold roll forming machineparts manufacturing and installation. The tour... | |

| LIGHT GAUGE STEEL FRAMING C PURLIN ROLL FORMING MACHINEE | BOSJ Light Gauge Steel Roll Forming Machine is suited to construct walls, floors and roofs for 1 – 3 level residential, modular and transport... | |

| PROFILE ROLL FORMING MACHINE | The steel profile roll forming machinemainly consists of four parts: The first is the input section - in this section, the material is loaded at... | |

| STEEL ROLL FORMING MACHINE | BOSJ,roll forming machine manufacturers in china,estabilished in 2004, As a leading producer of many types of china cold roll forming machinein Chi... | |

| CEILING ROLL FORMING MACHINE | Ceiling channel roll forming machine is a special machine designed for the ceiling industry. It has high speed and high efficiency, stable performa... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | 卖方: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |