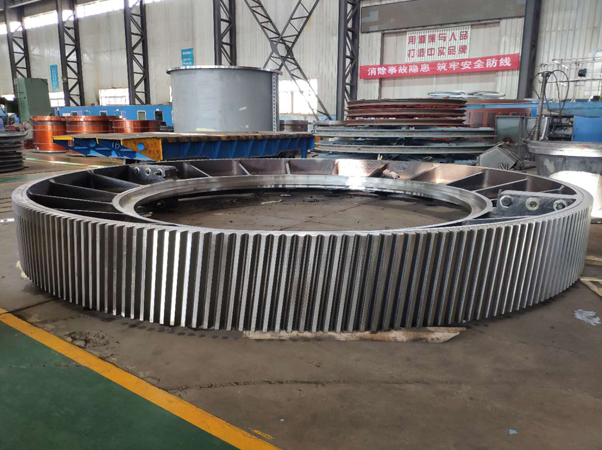

Girth Gear

CIC is the casting & forging center in central-south China, possessing a 50t electric arc furnace, 60t LF ladle refining furnace, and 60t VD/VOD refining furnace, etc. As the girth gear manufacturers, we can pour 350t liquid steel one time and yields more than 200,000t of high-quality liquid steel and can produce the high-quality steel of more than 260 steel grades such as carbon steel, structural alloy steel and the structural steel, refractory steel and stainless steel of special requirement. The maximum weight of casting, gray casting, graphite cast iron and non-ferrous casting is 200t, 30t, 20t and 205t separately.

Feature of kiln girth gear

lModule Range: 10 Module to 70 Module.

lDiameter: Min 800mm to 16000 mm.

lWeight: Max 120 MT single piece.

lThree Different Designs: Fabricated steel - forged ring - rolled plate

Standards/Certificates: • UNI EN ISO • AWS • ASTM • ASME • DI

Our Advantages of rotary kiln girth gear

lProducts with Customers' Designs

lStrong Machining & Heat Treatment Abilities

lStrict Quality Control

lPrompt Delivery

Experience in Cooperation with Fortune 500 Companies

Process of Grith Gear

lForging or Casting

lNormalizing & Tempering-Proof Machining

lQuenching & Tempering

Finish Machining (Teeth Grinding)

Technical Parameter of Grith Gear

|

Item |

Description |

|

|

1 |

Diameter |

≤15m |

|

2 |

Module |

≤45 |

|

3 |

Material |

Cast Alloy Steel, Cast Carbon Steel, Forged Alloy Steel, Forged Carbon Steel |

|

4 |

Structure From |

Integrated, Half to Half, Four Pieces and More Pieces |

|

5 |

Heat Treatment |

Quenching & Tempering, Normalizing & Tempering, Carburizing & Quenching & Tempering |

|

6 |

Tooth Form |

Annular Gear, Outer Gear Ring |

|

7 |

Standard |

ISO, EN, DIN, AISI, ASTM, JIS, IS, GB |

InspectionandTestOutlineofGirthGear

|

Item |

Inspection Area |

Acceptance Criteria |

Inspection Stage |

Certificates |

|

|

1 |

ChemicalComposition |

Sample |

Material Requirement |

When SmeltingAfter Heat Treatment |

Chemical CompositionReport |

|

2 |

MechanicalProperties |

Sample (Test Bar on the Gear Body) |

Technical Requirement |

After Heat Treatment |

Mechanical PropertiesReport |

|

3 |

HeatTreatment |

Whole Body |

Manufacturing Standard |

During Heat Treatment |

Heat Treatment ReportCurves of HeatTreatment |

|

4 |

HardnessTest |

Tooth Surface, 3 Points Per 90° |

Technical Requirement |

After Heat Treatment |

Hardness Teat Report |

|

After Semi FinishMachining |

|||||

|

5 |

DimensionInspection |

Whole Body |

Drawing |

After Semi FinishMachining |

Dimension InspectionReport |

|

Finish Machining |

|||||

|

6 |

Magnetic Power Test (MT) |

Tooth Surface |

Agreed Standard |

After Finish GearHobbing |

MT Report |

|

7 |

UT |

Spokes Parts |

Agreed Standard |

After Rough Machining |

UT Report |

|

After Welded |

|||||

|

After Semi FinishMachining |

|||||

|

8 |

PT |

Defect Area |

No Defect Indicated |

After DiggingAfter Welded |

PT Record |

|

9 |

Mark Inspection |

Whole Body |

Manufacturing Standard |

Final Inspection |

Pictures |

|

10 |

AppearanceInspection |

Whole Body |

CIC's Requirement |

Before Packing(Final Inspection) |

|

|

11 |

Anti-rustInspection |

Whole Body |

Agreed Anti-rust Agent |

Before Packing |

Pictures |

|

12 |

PackingInspection |

Whole Body |

Agreed Packing Form |

During Packing |

Pictures |

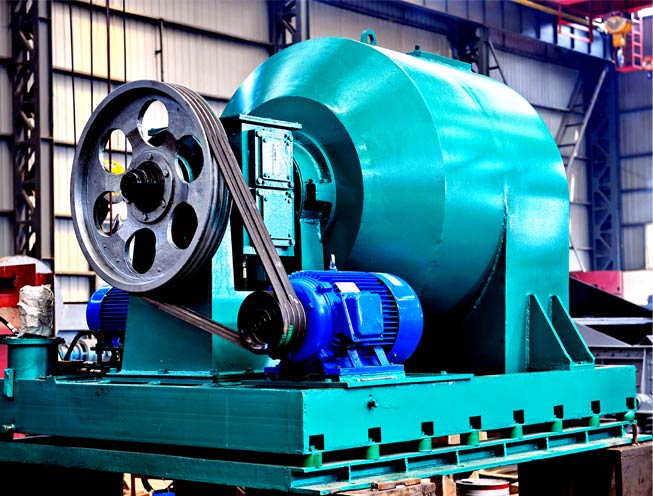

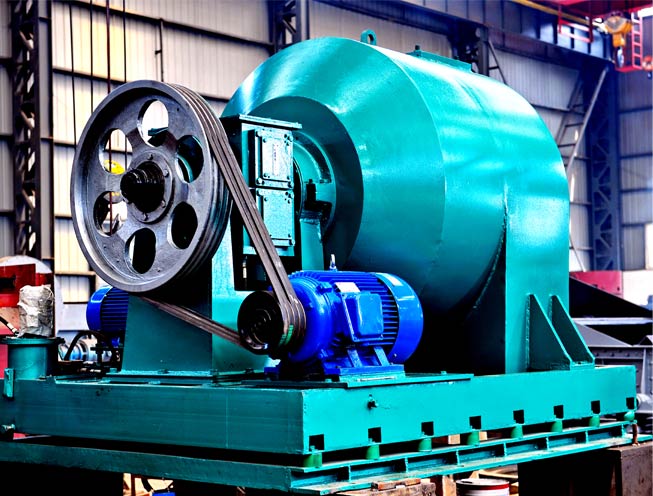

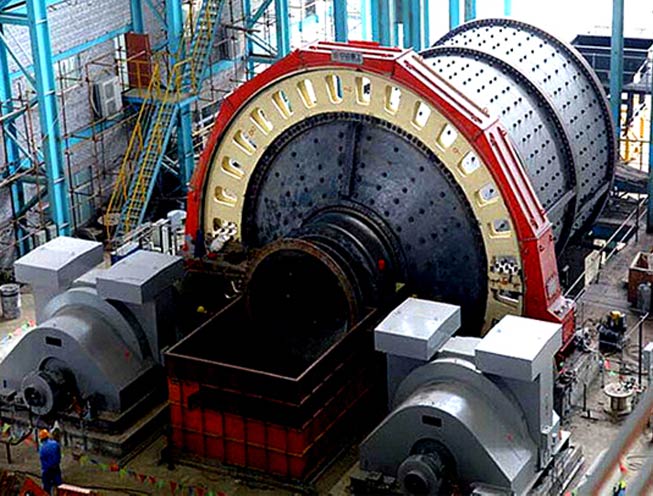

Part Performance of Girth Gear

|

Material |

OD/mm |

Module |

Application |

Client |

|

|

1 |

T30MoCrNi14 |

10394 |

28 |

SAG |

Romania |

|

2 |

T30MoCrNi14 |

8356 |

28 |

Ball Mill |

|

|

3 |

G35CrNiMo6-6 |

5910 |

39 |

Rotary Kiln |

KHD |

|

4 |

G34CrMo4 |

6180 |

30 |

Cement Mill |

|

|

5 |

G35CrNiMo6-6 |

6362 |

42 |

Rotary Kiln |

|

|

6 |

G35CrNiMo6-6 |

6362 |

42 |

Rotary Kiln |

|

|

7 |

G34CrMo4 |

5909 |

39 |

Rotary Kiln |

|

|

8 |

G34CrMo4 |

6362 |

42 |

Rotary Kiln |

|

|

9 |

G34CrMo4 |

6621 |

39 |

Rotary Kiln |

|

|

10 |

ZG 35CrNiMo |

5452 |

45 |

Rotary Kiln |

Tunisia |

|

11 |

ZG 35CrMo |

4868 |

22 |

Cement Mill |

|

|

12 |

G34CrMo4 |

42 |

Cement Rotary Kiln |

Giant→KHD |

|

|

13 |

G35CrNiMo6-6 |

7369 |

45 |

Cement Rotary Kiln |

|

|

14 |

G34CrMo4 |

5964 |

42 |

Cement Rotary Kiln |

|

|

15 |

ASTM 4140 |

7289 |

/ |

American Rexnord |

|

|

16 |

ZG42CrMo |

6972 |

25 |

Cement Rotary Kiln |

Hong Kong |

|

17 |

ZG42CrMo |

3400 |

25 |

Sugar Dryer |

Japan TSK |

|

18 |

ZG42CrMo |

3480 |

20 |

Sugar Dryer |

|

|

19 |

ZG310-570 |

3360 |

20 |

Fertilizer Dryer |

Malaysia |

|

20 |

ZG310-570 |

3640 |

20 |

Fertilizer granulator |

|

|

21 |

ZG42CrMo |

4100 |

32 |

Fertilizer Cooler |

|

|

22 |

ZG42CrMo |

5550 |

25 |

Fertilizer Dryer |

|

|

23 |

ZG42CrMo |

3040 |

20 |

Fertilizer granulator |

|

|

24 |

GS35CrMoV |

7318 |

/ |

Venezuela |

|

|

25 |

ASTM 4140 |

7560 |

40 |

Dryer |

|

|

26 |

ZG42CrMo |

6633 |

Rotary Kiln |

Korea |

|

|

27 |

ZG42CrMo |

5688 |

36 |

PTA Dryer |

Japan TSK |

As one of heavy machinery manufacturers, we also have types of sludge centrifugefor sale, if you have needs, please contact us.

在线联系供应商

Other supplier products

| Liner | Liner is to protect the shell from direct impact and friction of grinding materials and is also used to modulate the motion of grinding material. I... | |

| Horizontal Centrifuge Machine | TWZ series horizontal vibratory centrifuge belongs to the centrifugal dewatering machine, the series of horizontal vibratory centrifuge is mainly u... | |

| Horizontal Centrifuge Machine | TWZ series horizontal vibratory centrifuge belongs to the centrifugal dewatering machine, the series of horizontal vibratory centrifuge is mainly u... | |

| SAG Mill | Semi autogenous millor SAG mills as they are often called, can perform grinding operations equivalent to two or three stages of crushing and screen... | |

| Wet Grid Ball Mill | Wet ball millis a kind of energy-saving industrial grinding mill which adopts rolling bearings and has high efficiency. Wet grid mining ball mill p... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | 卖方: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |