PAPER DRUM PRODUCTION LINE

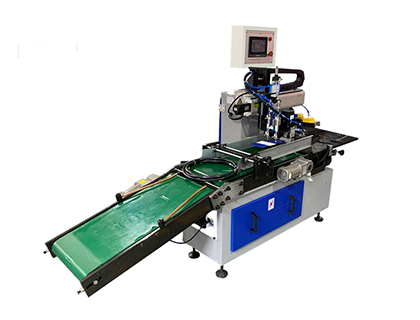

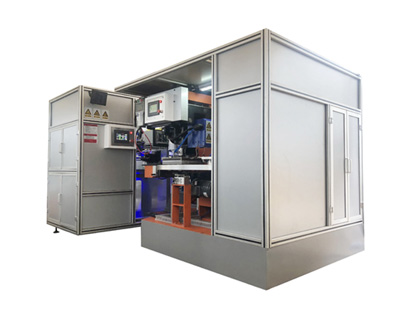

The equipment is customized for the drum paperindustry, realizing the automatic production of welding and forming. With advanced laser continuous welding technology, the overall operation is simple. The touch screen is used to control the operation technical parameters of the equipment, and can automatically complete multiple processes such as feeding, cutting, welding, crimping forming, unloading, etc. The width of the steel strip can be adjusted freely without changing the mold. The equipment can realize seamless welding and achieve the best material saving effect.

HOW DOES PAPER DRUM PRODUCTION LINE WORK?

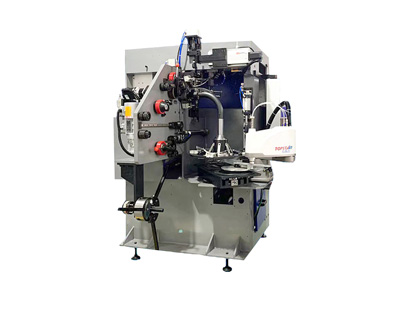

For the material of the paper drum is galvanized material, we use a high-power automatic laser welding machine. After seamless welding, the product is transferred to the crimping process through a robotic arm or a transmission device to complete automatic production.

FEATURES OF PAPER DRUM PRODUCTION LINE

1

Simple operation, full CNC, every worker can operate the equipment after learning. Arbitrary adjustment, the equipment is controlled by the program, and the welding size can be adjusted arbitrarily. Efficient, high-precision servo systems are used to initiate various machining steps at high speed.

2

High-quality laser continuous welding enables the weld seam to meet the highest demands. High energy saving, the equipment has an alarm system for no material and material blockage, and has an automatic shutdown function. The cost is low, and the equipment is completed by combining multiple processes, which completely solves the labor problem.

3

The equipment is suitable for laser welding of stainless steel strips in glass pot lids, enamel jars, trash cans, paper buckets, mesh baskets, screens and other industries. It is suitable for producing stainless steel rings of various widths, thicknesses and diameters. For laser seamless welding, it solves various production problems such as weak welds, uneven welds, unsightly welds and wasted material.

ADVANTAGES OF PAPER DRUM PRODUCTION LINE

paper drum

FIRST

No material alarm system

High-quality laser continuous welding enables the weld seam to meet the highest demands. Efficient, high-precision servo systems are used to initiate various machining steps at high speed. High energy saving, the equipment has an alarm system for no material and material blockage, and has an automatic shutdown function.

drum paper

SECOND

Easy to use

Simple operation, full numerical control, can be adjusted arbitrarily, the equipment is controlled by the program, and the welding size can be adjusted arbitrarily. Precise cutting and welding of strips is possible. The surface of the welded product is smooth and beautiful, without burrs, and the desoldering rate is less than 0.1%.

Now the paper drum priceis affordable, if you have needs, please contact us.

If you want to know more kinds of automatic laser welder, please visit our website.

在线联系供应商

Other supplier products

| LONGITUDINAL SEAM WELDER | Xihe automatic longitudinal seam welding machineis the most versatile aluminum seam welder on the longitudinal welding machinemarket. It is designe... | |

| STAINLESS STEEL WELDING MACHINE | Laser welding machine for stainless steeladopts laser continuous welding technology, high-precision servo motor feeding, high-speed clamping and ot... | |

| STAINLESS STEEL BELT LASER WELDER | The equipment adopts advanced laser tool weldingtechnology, and the overall operation is simple. The touch screen is used to control the operation ... | |

| MESH BASKET STAINLESS STEEL BELT AUTOMATIC PRODUCTION LINE | MESH BASKET STAINLESS STEEL BELT AUTOMATIC PRODUCTION LINE The equipment adopts advanced laser continuous welding technology, through the automati... | |

| ENAMEL POT STAINLESS STEEL BELT LASER WELDER | ENAMEL POT STAINLESS STEEL BELT LASER WELDER The equipment adopts advanced laser continuous welding technology, and the overall operation is simpl... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | 卖方: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |