Fiber Laser Tube Cutting Machine for Flexible Manufacturing System Manufacturer

Industry 4.0 time, with advanced CNC controller to realize production line ERP management. Realize a completely automatic production model.

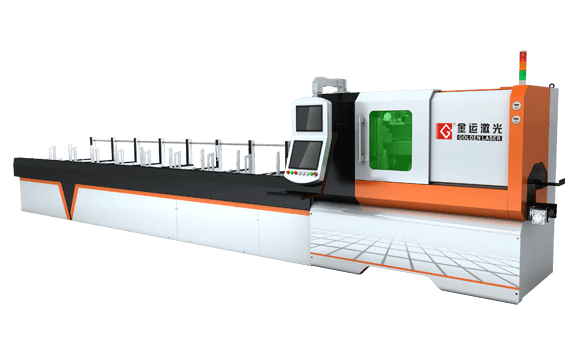

Overview of Fiber Laser Tube Cutting Machine Flexible Manufacturing System

The integration of laser cutting and sorting will help customers achieve flexible planning, production tracking, and quality monitoring. While improving equipment utilization, it will reduce quality failures and manufacturing costs, shorten delivery cycles, and achieve intelligent and digital production mode.

Theauto feeding fiber laser cutting machineproduced by our company has different types -- from 1000w fiber laser cutting machine to 8000w laser cutting machine -- each type sells at a different price.

Application of Fiber Laser Tube Cutting Machine FMS

Fiber cutting machineFMS in the food processing pipeline

This is a German 150-year-old food company. According to customer requirements, a set of copper fast cutting and cleaning and packaging production lines is customized. Reached unattended, in line with German security levels.

Highlights of Fiber Laser Tube Cutting Machine FMS

Automatic Loading and Unloading System

The fully automatic loading and unloading system is controlled by the CNC system and seamlessly connected with the laser tube cutting machine to realize the hoisting and loading of the whole bundle of tubes. The control system intelligently divides and composes the tubes and the automatic conveying process. A pipe component is sent to the position to be inspected for automatic measurement, saving manual loading and unloading costs, and improving work efficiency.

Synchronous Processing Of Industrial Robot

The 3D industrial robot can carry out automatic feeding of unconventional length pipes and unloading of waste after cutting. At the unloading end, the industrial robot is matched with the crawler. It can visually recognize and automatically grab workpieces, and automatically palletize and store workpieces after classification.

Intelligent Operating System

It adopts bus control mode, supports touch screen operation mode, and has 7 intelligent management modules for planning, production, process, debugging, diagnosis, maintenance, and setting. The intelligent operating system of the fiber laser tube cutter FMS has its own tube material library and integrates a variety of tube splicing processes.

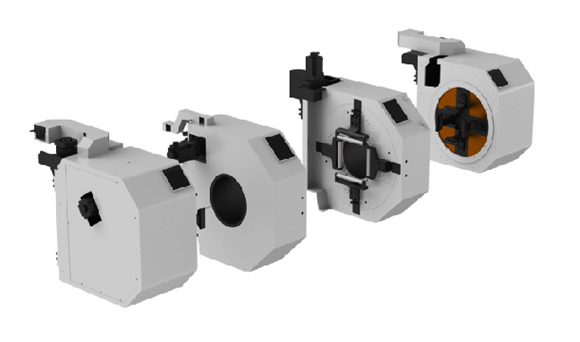

Full Stroke Chuck

No manual adjustment is required. Intelligent pressure feedback system automatically adjusts pressure according to different pipe diameters and thicknesses. Intelligent identification and clamping of various pipe materials, real-time monitoring and alarm, safe and efficient.

Automated Workflow of Fiber Laser Tube Cutting Machine FMS

Step 1

Loading a bunch of round tubes to the auto feeder of the fiber cutting laser machine, which has the advantage of high efficiency.

Step 2

Smart laser tube cutter equipped with fully electric floating support and auto-focusing laser cutting head to ensure high precision during cutting.

Step 3

After the copper pipe is cut, the customized receiving tract will receive the finished parts pipe, and then the pneumatic feeding fixture will feed it.

Step 4

Industrial robots will automatically clamp and clean workpieces.

Step 5

Industrial robots will palletize workpieces and can put more than 2000 tubes in one box.

Automation of Fiber Laser Tube Cutting FMS

Automatic loading and unloading system

Equipped with a fully automatic bundle loader and a crawler rewinding device, it reduces the dependence on labor and makes pipe cutting so easy.

6-axis industrial robot

A series of automatic actions such as automatic grabbing, transfer, workpiece classification, automatic palletizing, and warehousing can be realized.

Components of Fiber Laser Tube Cutting Machine FMS

Based on the industry development and the needs of automation programs in the market, Goden Laser, one of the most professional laser cutting machine suppliers in China, develops its own fiber laser tube cutting machine FMS. Generally speaking, the production line of fiber laser tube cutting machine FMS consists of the laser cutting machine programming system, the storaging and delivering system of raw materials, the automatic feeding and discharging device, the laser cutting machines and the industrial robots.

The fiber laser tube cutting machine FMS by Golden Laser is now applied in the food processing pipelien and can be used in more fields such as engineering machinery, auto parts manufacturing, and logistics industry.

Advantages of Cutting Machine FMS

Our fiber laser tube cutting machine FMS has thefollowingedges:

- It realizes fully automated production and intelligent manufacturing managenment.

- The unattented mechanism or system helps update the production flow and improve the management automation level of the Company.

- Therefore, the fiber laser tube cutting machine FMS helps lower the labor cost and enhance the efficiency and benefits of the enterprises.

As one of the most professional fiber cutting machine manufacturers, we provide china pipe laser cutting machine, low cost tube laser,auto feeding fiber laser cutting machine, fiber laser pipe cutting machine, etc. Contact us to know more.

在线联系供应商

Other supplier products

| Cost-Effective Laser Pipe/Tube Cutting Machine Supplier | Low investment, high value, unique installation-free design, featured by out-of-box service. Overview of Cost-Effective Metal Tube Laser Cutting... | |

| Heavy Duty Tube Laser Cutting Machine Manufacturer | Overview of Heavy Duty Tube Laser Cutting Machine Large tube laser cuttinguses a focused high-power-density laser beam to irradiate the workpiece,... | |

| Overview of Heavy Duty Tube Laser Cutting Machine | Large tube laser cuttinguses a focused high-power-density laser beam to irradiate the workpiece, so that the irradiated material quickly melts, vap... | |

| Operating Principle and Characteristics of Fiber Laser Machine | GOLDEN LASER(stock number 300220) is a china pipe cutting machinemanufacturer which focuses on the application and practice of the laser industry. ... | |

| Fiber Laser Tube Cutting Machine Used For 4 mm Aluminum Pipe Cutting of Automobile Pipe Fittings | GOLDEN LASER (stock number 300220) is a china pipe cutting machinemanufacturer which focuses on the application and practice of the laser industry.... |

Same products

| XD-MAX Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |