How Does Induction Heating Work

How does induction heating work

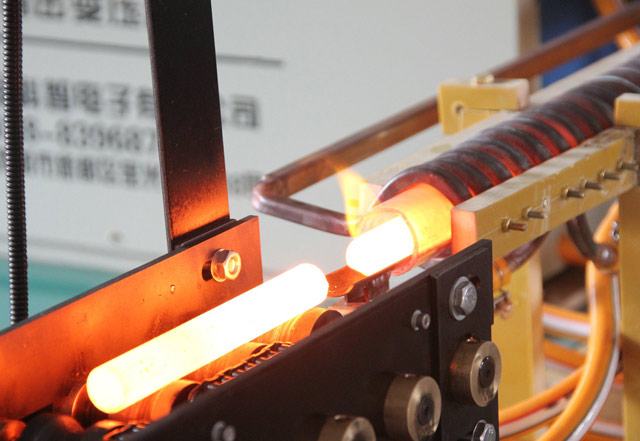

Induction heating is an application that based on the magnetic induction principle. It uses the eddy current to heat the part placed in the alternating magnetic field. (The part is metal or nonmetal conductor like graphite.)

In the induction coil (inductor/coil), the high-frequency alternating current will first generate an alternating electromagnetic field. Then, the magnetic line will form a loop when passing through the metal part/nonmetal conductors. Following that, an induced current will be generated in the cross-section of the part to be heated ( we normally call this type of current as eddy current). Finally, the eddy current of the part to be heated will heat up fast under the action of the resistance of the part, so as to eventually realize the purpose of heating the parts.

A complete set of induction heating machine includes the high-frequency heating generator (power supply), transformer, and coil:

The generator for high-frequency induction heating is responsible for converting the power supply ( such as 3P380V/50Hz or 3P220V/60Hz, or single-phase power supply) into the form of high-frequency, high-voltage, and low-current output.

The transformer of the metal heating machine is responsible for converting the high frequency, high voltage, and low current provided by the high-frequency heating generator into the output mode of high frequency, low voltage, and large current. Also, the transformer needs to isolate or adapt the output according to the different heating applications.

The coil is responsible for forming a strong high-frequency magnetic field around it after passing high-frequency, low-voltage, and large current. Generally, the larger the current, the higher the magnetic field strength. The coil needs to be designed according to the shape of the heated part and the heating position. Thus, it is not limited to the spiral tube or flat form.

As a professional induction heater manufacturer, JKZ has high-quality induction heating devicefor sale. Welcome to contact us if needed.

在线联系供应商

Other supplier products

| Portable Induction Welding Machine | JKZ is a professional induction heater factory,we provide induction heating equipment, induction welding equipment, portable induction heating mach... | |

| Induction Heating Machines | JKZ Induction Heating has been engaged in the manufacturing of induction heating equipmentsfor nearly 30 years. At present, there are currently mor... | |

| MFS-120A 1-8KHZ 120KW 182A Medium Frequency Induction Heating Machine | MFS-120A 1-8KHZ 120KW 182A Medium Frequency Induction Heating Machine MFS120A induction heating power supply adopts IGBT as the core component. As... | |

| Induction Heating Machines In Automotive Industry | The automobile manufacturing industry is the most typical and core application field of JKZ induction heating equipment. Situations like shafts sur... | |

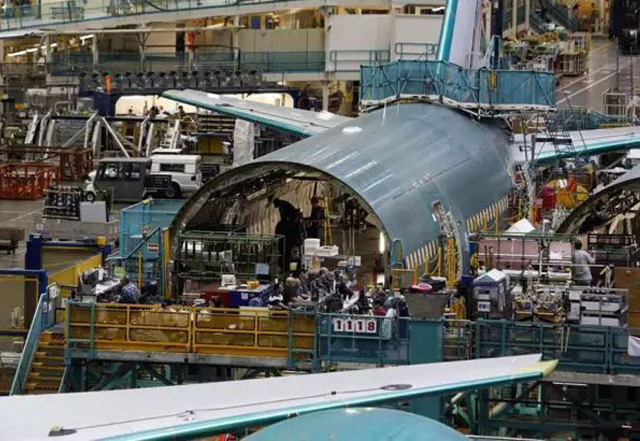

| Induction Heating Machines In Aviation And Aerospace | Aviation and aerospace are manifestations of high standard industrial capabilities. Induction heating is widely used in the aerospace industry, and... |

Same products

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... | |

| 3 in1 Decoiler Leveler Feeder | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | 3 in1 Decoiler Leveler Feeder For Thin Plate(0.3-3.2mm) The 3-in-1 servo feederintegrates four f... | |

| NC Servo Feeder (0.1-3.0mm) | 卖方: Dongguan YouYi Precision Automation Equipment Co., Ltd. | NC Servo Feeder (0.1-3.0mm) Our standard servo feederis engineered for precision coil feeding of... | |

| Uratech 40 Taper CNC Tower – CAT 40 Tool Cart & CNC Tool Holder Storage | 卖方: Uratech USA Inc | TheUratech 40 Taper CNC Toweris the ultimate solution for organizing and protecting your CNC tool... |