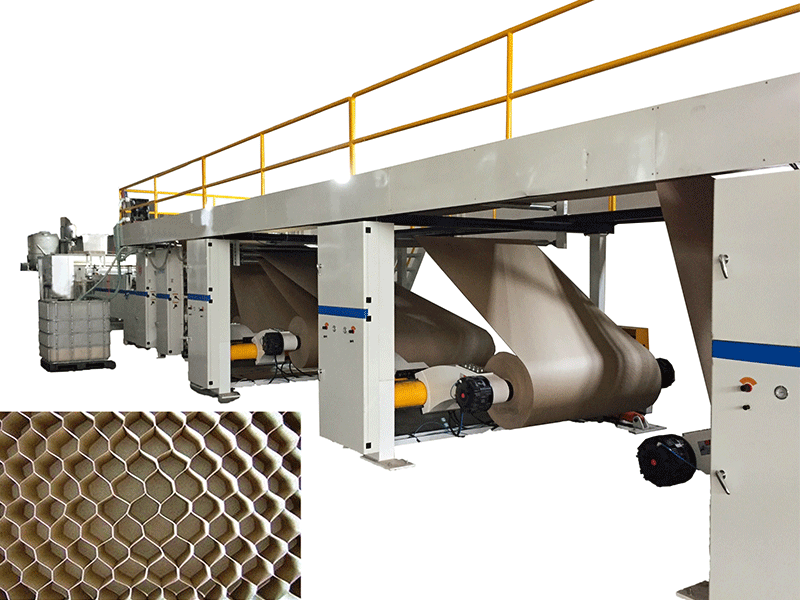

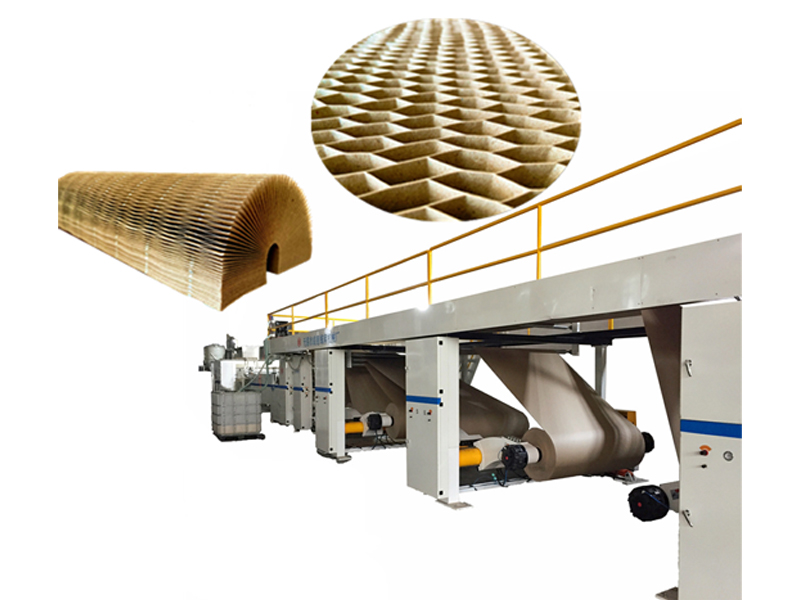

Honeycomb Paperboard Machine

The honeycomb panel machineis composed of two parts Honeycomb Paper Core Machine and Honeycomb Paper Lamination Machine. This honeycomb paperboard machineproduction line includes a Heavy load hydraulic paper stand, a Paper core gluing machine, a Paper core conveying pressing machine, a Dryer, Paper cutter, Paper core conveyer, Motors and electrical parts, a Paper core expanding & pressing machine, Paper core expanding dryer, Laminating gluing machine1, Heavy load hydraulic paper stand, Hot re-pressing machine 1, Laminating gluing machine 2, Hot re-pressing machine 2, Cold pressing machine, Transverse cutting machine, Paper board conveying machine, Electrical parts. Our paper honeycomb manufacturersmature production lines to produce honeycomb paperboard. Our honeycomb paper board machines have the characteristics of advanced technology and fast production speed.

Advantages Of Honeycomb Board Machine

Our honeycomb board machine has the advantages of professional production, high degree of automation, advanced technology, reliable quality, advanced technology, stable and reliable performance.

Features Of Honeycomb Board Machine

Paper core bonding strongly, and the raw paper running smoothly.

The upper blade rest is made of steel castings, and the blade is made of high-speed steel which imported from Japan, with a hardness of HR 63 degrees. The lower blade rest is made of aluminum alloy, which is light in weight and high in strength.

Adjust paper core expanding speed by changing the frequency and speed according to different cell sizes when using honeycomb board machine.

Paper core pressing can improve the adhesion when paper core and surface paper laminating.

Honeycomb board machine can adjust frequency and speed individually.

Dual function gluing head:gluing surface paper or gluing paper core.

Gluing rollers of fine grinding, hard chrome plated surface.

The main cylinder of honeycomb board machine adopts Φ190×12 seamless steel tube.

The scraper roller uses an eccentric wheel to adjust the amount of glue.

Applications Of Honeycomb Board Machine

Honeycomb paperboard is made according to the principle of the natural honeycomb structure. Honeycomb board machine connects the corrugated base paper into countless hollow three-dimensional regular hexagons by glue bonding to form a whole force-bearing part-the paper core and the adhesive surfaces on both sides. A new type of sandwich structure is an environmentally friendly and energy-saving material made of paper.

Honeycomb cardboard used for packaging and transportation can not only protect the product but also reduce transportation costs. Specific applications are cushioning pads, gussets, etc.

Honeycomb paperboard has good cushioning properties, so it can also be used as a cushioning pad and isolation board for packaging like corrugated paperboard, and its honeycomb sandwich structure makes its cushioning performance better than corrugated paperboard. When using it as a corner pad, generally cut one layer of paper from the core paper according to the size of the cardboard, leaving only the other layer of paper not to be cut, relying on this layer of paper to connect several pads on different sides together, and then put on the corresponding parts of the contents to be protected.

If you need any kinds of honeycomb core machine, please contact us, as a professional honeycomb making machine supplier, San Machineryis willing to offer you high quality products.

在线联系供应商

Other supplier products

| Paper Slitting Rewinding Machine | Paper slitting and rewinding machineis used to slit the big paper rolls into small paper rolls , then rewind them. The hydraulic shaftless paper ho... | |

| Paper Edge Protector Recutter | Paper Angle Board Cutter This machine is used to re-cut paper protectors into smaller pieces. Feeding is by hand. Cutting is controlled by foot. ... | |

| Honeycomb Paper Machine | Honeycomb paper making machineincludes a complete production line, which can be divided into two parts: honeycomb paper core line and honeycomb pap... | |

| Honeycomb Paper Core Machine | Honeycomb paper core machine includes 2 models. There are 7 parts: Heavy load hydraulic paper stand, Paper core gluing machine, Paper core conveyin... | |

| Honeycomb Paper Core Expander | This paper core expander is applied to expand and dry the honeycomb paper core. By heating and drying, evaporating the water in it, and then stretc... |

Same products

| XD-MAX Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-MAX Winch for Drone The XD-MAX Winch for Droneis a high-performance aerial lifting solution d... | |

| XD-55 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-55 Winch for Drone Introducing the XD-55 Winch for Drone—an advanced lifting system eng... | |

| XD-10 Winch for Drone | 卖方: NEW WING ADVANCED (TIANJIN) TECHNOLOGY CO., LTD | XD-10 Winch for Drone SAFE, EFFICIENT AND CONVENIENT.Your reliable and intelligent air transport... | |

| Uratech ER16 Collet Rack – CNC Collet Storage for ER, DR & RD 16 Series | 卖方: Uratech USA Inc | TheUratech ER16 collet rackis a premium storage solution designed for CNC shops, toolrooms, and m... | |

| Uratech Tool scoot cart for 50 taper tool holders | 卖方: Uratech USA Inc | Maximize efficiency in your machining operations with our50 taper CNC tool carts, the ultimate so... |