Two Component Silicone Sealant Dispensing Machine Adhesive Dispensing Glue Application Equipment Dosing Equipment

Fully automatic polyurethane resin glue dispensing robot two components glue automatic meter-mix dispensing line 2 Part Silicone plyurethane epoxy potting dispensing machine AB Resins compound dosing dispensing potting system ,2K potting technology AB glue dispensing machine Epoxy dispensing machine Two-component dispensing machine,Dual-component dispensing machine Meter-mix dispensing machine,Resin dispensing machine Adhesive dispensing system,Dispensing robot with high precision Dispensing valve, AB Liquid dispenser , Automated dispensing equipment

The AB glue mixing/dispensing/potting machine, also known as the AB double-liquid glue dispensing machine, is an automated machine that specifically controls fluids and drips, coats, and pots the liquid on the surface of the product or inside the product to achieve sealing, fixation, waterproofing, etc. equipment, generally use two-component glue.

It is mainly used for the bonding, pouring, coating, sealing and dispensingof glue, oil and other liquids in product processes. The automatic glue dispensing machine can realize the filling of irregular shapes such as points, lines, arcs and circles.

The glue commonly used in glue dispensingmachines is generally two-component glue, also called AB glue. Of course, it is also suitable for single-component glue. Among them, glue A is the main agent and glue B is the curing agent. The most widely used glues on the market are epoxy resin, polyurethane, and silicone. The ratio to the curing agent is 1:1, 2:1, 5:1. 4:3, mostly 10:1

Application areas

ab glue potting/dispensing are often used for glue dispensingin LED display screens, LED energy-saving lamps, LED power supplies, LED light bars, computer power supplies, relay modules, sensors, PCB boards, and solar panels. , Coil inductor glue potting , flexible light strip glue dispensing, point light source glue potting, LED surface mounting screen glue dispensing/potting , etc.

General classification

(1) Simple ab glue potting/dispensing machine, the composition is relatively simple, with two barrels and one cylinder. The glue is pressed out and mixed by gas pressure. The general ratio is roughly 1:1. It is mainly used in some low-end machines for glue dispensing. Products whose process requirements are not too strict.

(2) Semi-automatic ab glue potting/dispensing machine. This type of glue filling machine can automatically mix various proportions of glue. However, this type of glue dispensingmachine does not have a motion control platform and directly injects glue into the product to be filled. It is generally applicable. For LED energy-saving lamps, power supplies.

(3) Automatic ab glue potting/dispensing machine. This type of glue filling machine can not only realize automatic mixing of various proportions of glue, but also can meet the mixing and dispensingoperation requirements in the ratio of 1:1---10:1, and is equipped with a motion control platform. It can take a straight line or a three-dimensional path. Among them, the three-dimensional path is more advanced. It is generally controlled by a computer and is suitable for various types of products. Automatic glue dispensingmachines are used for glue dispensing in large areas and products that require relatively uniform glue dispensing. Among them, LED modules are the most popular.

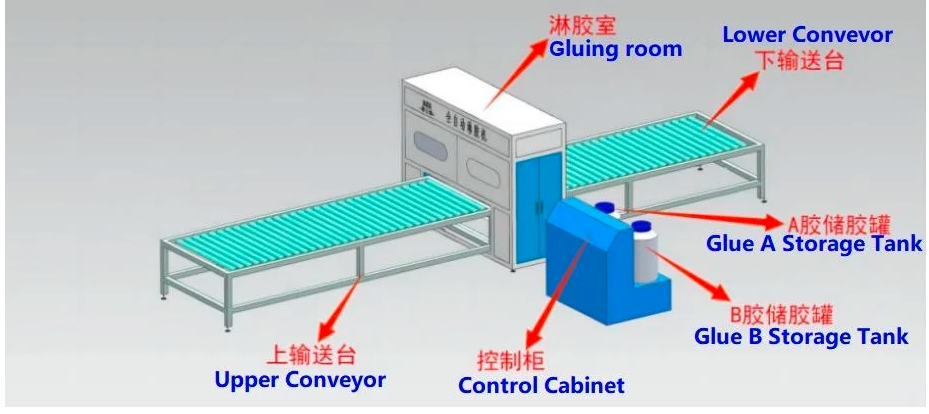

(4) Online glue dispensing machine, this type of glue dispensingmachine has the highest degree of automation and fully automatic glue dispensing operation in the assembly line. It has been successfully used in the assembly line glue dispensingoperation of battery covers and bulbs.

Operation type classification

There are two main control operation modes for domestic glue dispensingmachines, namely touch screen control and computer control:

1. Touch screen control

Built-in touch screen to control the proportion of glue dispensingand mixing, the amount of glue and the speed of glue dispensing;

2. Computer control

The computer control panel is used to set the relevant glue dispensingpath, which is simple and fast. Through the visual system, it is clearly visible whether the ab glue potting/dispensing position is deviated, so that it can be processed as soon as possible to ensure the quality of the glue dispensingproduct

Applicable liquids

Various solvents, adhesives, paints, chemical materials, solid glue, etc., including silicone, EMI conductive glue, UV glue, AB glue, quick-drying glue, epoxy glue, sealant, hot glue, grease, silver glue , red glue, solder paste, thermal paste, solder mask, transparent paint, screw fixing agent, woodworking glue, anaerobic glue, acrylic glue, anti-wear glue, crystal glue, pouring glue, speaker glue, instant glue, rubber, paint , enamel paint, lacquer, ink, pigment, etc.

How to buy

Before purchasing a glue dispensing machine, you first need to understand two things:

1. Basic characteristics of the glue used

a) What kind of glue is it? One-component or two-component (AB glue)?

b) If it is two-component, what is the weight ratio of AB glue?

c) viscosity and density of glue,

d) How long does it take for the glue to start curing, and how long does it take for the glue to fully cure?

e) How to pack the glue,

2. Requirements that the glue dispensing process needs to meet

a) What are the glue filling accuracy requirements and the amount of glue used for each product?

b) Glue is used for potting, pasting, insulation, moisture-proof, dripping,

c) How to implement the glue dispensingoperation?

Selection principle

1. Glue: A single-component glue dispensingmachine is used for ordinary glue, a two-liquid glue dispensing machine is used for AB glue, a PU glue filling machine is used for PU glue, and a specific syringe is used for UV glue.

2. Glue dispensing process: For ordinary glue dispensing, a semi-automatic glue dispensing machine (such as foot control) is used. For precise positioning and marking, a desktop, three-axis, circle drawing and other glue dispensingmachines with automatic functions are used. The automation function of the glue dispensing machine is actually an accessory function. The glue dispensing machine plays more of a role in controlling glue. Other functions can be realized with the help of automated manipulators.

3. Work efficiency and environment: There are few products and no pursuit of efficiency, so manual glue guns are used; for outdoor work, glue guns are used. It is required to accurately control the glue output and use machines. If automated dispensing is required, use a machine with automated functions.

4. Cost: There are various glue dispensing solutions. Not all glue dispensing requires the use of machines, and not all automated glue dispensing must be attached to the glue dispensing machine. From a cost perspective, if a certain glue requires a too expensive machine, you can consider replacing the glue. If the price of a dispenser with automation is too high, consider moving the product instead of the dispensing head.

Configure pump body

1. Gear pump

Applicable to glue without fillers, corrosive and viscosity less than 20000CPS

Two gears of the same size mesh and rotate with each other in a tightly fitting housing. The inside of this housing is similar to an "8" shape. The two gears are installed inside. The outer diameter and both sides of the gears are closely matched with the housing. The material from the storage barrel enters between the two gears at the suction port and fills this space. It moves along the housing with the rotation of the teeth, and is finally discharged when the two teeth mesh.

2. Screw pump

It is suitable for glues with precipitation (including partial fillers), low corrosiveness, and viscosity less than 30,000 CPS.

The screw pump works according to the rotary meshing volumetric principle. The main working parts of the screw pump are the eccentric screw (rotor) and the fixed bushing (stator). Due to the special geometric openings of the two parts, separate sealed cavities are formed. The medium flows uniformly in the axial direction. The internal flow rate is low and the volume remains constant. The pressure of the screw pump is stable, so it does not produce turbulence and agitation.

Its biggest features are strong adaptability to the medium, stable flow, small pressure pulsation, and high self-priming ability, which cannot be replaced by any other pump type. In terms of later maintenance, the screw pump only needs to replace the stator (screw guard). sets), which greatly reduces costs.

Problems

The most common problem encountered with glue dispensing machines is valve problems. The following are effective methods to solve problems that often occur when using glue valves.

1. Glue valve dripping

This situation often occurs after the rubber valve is closed.

95% of this situation is caused by the diameter of the needle used being too small.

A needle that is too small will affect the flow of the liquid and cause back pressure, resulting in leakage soon after the valve is closed. A needle that is too small will also affect the air bubble removal action of the valve when it is first used. Just replace it with a larger needle. can solve this problem.

The tapered beveled needle creates the least back pressure and allows the smoothest fluid flow.

在线联系供应商

Other supplier products

| Aluminum Honeycomb Panel 2 component PU Glue Bonding Machine PU dispenser PU potting laminate machine | How to glue EPS XPS or aluminum honeycomb panels | EPS XPS foam panel automatic glue spray line FEATURESAdvanced control process, ea... | |

| Auto Glue Spray Machine CNC Epoxy Resin Dispensing Machine 2 Part Epoxy Silicone Polyurethane Epoxy Machine | Fully automatic polyurethane resin glue dispensing robot two components glue automatic meter-mix dispensing line 2 Part Silicone plyurethane ep... | |

| Sips sandwich panel glue spraying machine | The glue Spraying line is based on the reform of the traditionalroller glue machine process. With the marketization and standardscale of stainles... | |

| Online Two Component Ab Glue Epoxy Automatic Vacuum Dispensing Potting Robot Ab Epoxy System Two Part Dosing Machine | ab glue mixing and dosing machinePotting and encapsulation is the process of embedding products & assemblies in a liquid resin (potting compoun... | |

| Automatic 2 Part Ab Silicone Sealant Mixing Dispenser for LED Lamps | Full Automatic Potting Machine Ab Glue Dispenser Machine for LED Strip Light Potting and encapsulation is the proces... |

Same products

| Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Inclined Belt Planetary Vertical Shaft Concrete Mixing Plant Why Choose anInclined Belt Planetar... | |

| Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift | 卖方: Yousheng Machinery Equipment Co.,Ltd | Improved Vertical Shaft Planetary Concrete Mixing Plant With Hopper Lift Vertical Shaft Planetar... | |

| High-Discharge Mobile Concrete Batching Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | High-Discharge Mobile Concrete Batching Plant High-Discharge Mobile Concrete Batching Plantinteg... | |

| Forced Mobile Concrete Plant | 卖方: Yousheng Machinery Equipment Co.,Ltd | Forced Mobile Concrete Plant Introducing our versatile forced concrete mixer: compact for tight ... | |

| Waste Aluminum Plastic Pyrolysis Plant | 卖方: Shangqiu Sihai Energy Technology Co.,Ltd | Waste Aluminum Plastic Pyrolysis Plant The refining of waste aluminum and plastic mainly uses a ... |