Home Appliance Molding Parts

Household Appliances Mould Parts

High Gloss Plastic Finish Parts

High gloss polish finishing plastic injection molded parts

The part is thin and flat, the function is a window, door, or cover of some household appliance, Therefore, the plastic parts are required beautiful appearance and the surface is easy to clean. Mould cavity steel can choose ASSAB8407 or Stavax S136. Transparent PC, PMMA, etc. are very suitable for the production of such products. 1 drop hot bush with manifold/ side gate

From prototype molds to mass production serious moulds, whether your product is simple or complex, HanKing team has enough technical knowledge and different plastic injection moulds experience to support you, our 2000 square meters facility and 45+ staffs strive to provide you with most reasonable cost plastic injection mould while meeting all quality requirements of you at the same time.

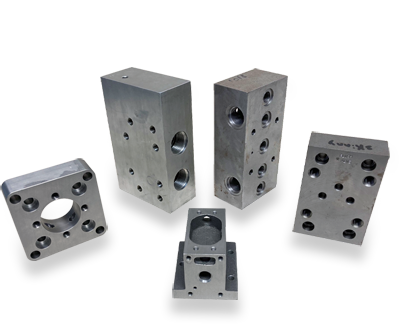

Our Mold Tolerance

Plates and Mold Base Components: ± 0.013 mm (± 0.0005 in)

Cavity components: ± 0.005 mm (± 0.0002 in)

Common plastic injection mould steel: ASSAB, LKM, FINKL STEEL, ThyssenKrupp, Buderus, Schmolz Bickenbach AG, Daido Steel, ALCOA, AMPCO.

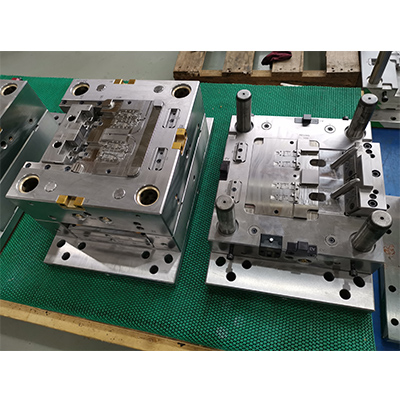

Home appliance tooling maker

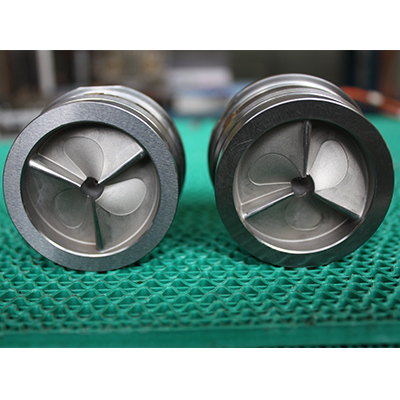

Coffee Grinder Hopper Cover Injection Mould

Cavity steel is 2343 ESR, surface high polish finishing

HanKing Mould has been providing various moulds as Multi Cavity Mold, two-color mould, insert molding, over molding, unscrewing mold, metal injection mold(MIM), as well as silicon mold.

When our engineer receives customer part drawing, they will review the part design to check mould opening possibility means if the mould function is ok. We will also take care of mould structure if it is cost economical as well as injection molding cost in the future. Hanking Mould strives to provide you with most reasonable cost plastic injection mould while meeting all quality requirements of you at the same time.

A plastic injection mold is a first and critical step for producing good quality parts. HanKing understands this and takes a lot of effort to improving our technical knowledge from tight tolerance, tooling fitting, mould assembly, and injection mold trial even to mould delivery, all the serious work is to provide our clients with high technical, and best quality plastic injection mould.

As one of chinese injection mold makers, we will do our best to meet all the needs of customers.

Other supplier products

|

|

Sewing Machine Frame Mould |

Sewing Machine Frame Mould

Large plastic frame plastic injection sewing molds, suited for oversize embroidery projects.

Mould Name: Embroidery ... |

|

|

3 Plate Mould 49113-21 |

Mould Name: 3 plate injection mold

Part Material: PBT GF15

Product Size: ф34.9x82.29

Product Description: Mischschraube kpl

Mould Cavity: 2 Cavitie... |

|

|

Plastic Insert Mold 139-86 |

Mould Name: Plastic Insert Mold

Part Material: PA + Glassfiber

Product Size: 11*30*1.3

Product Description: Stator

Mould Cavity: 4 Cavities

Mo... |

|

|

Gear Mould |

Gear Mold Design

Customs Plastic Gear

Mould Name:Custom Plastic Gear Mould

Part Material:POM Product Size:

Product Description: Plastic Motor Gear

... |

|

|

Over-Molding Parts |

The plastic injection overmoldingpart is a process that can bond different materials by the injection molding.

Over-molding in HanKing is a techno... |

供应产品

Same products