MIM Products

MIM Products

Whether you seek to economically manufacture a high-quality computer component, a small medical instrument, a firearm component, or other metal injection molding products, MIM Chinais an ideal process.

Wearability And Smart Wearability

In recent years, wearable devices have gradually completed market cultivation, and apple, Xiaomi, Huawei and other terminal brands continue to launch corresponding products. The booming smart wearable market also brings considerable development opportunities for MIM(metal powder injection molding) process. Intelligent wearable is a kind of wearable portable computing device. In order to make users wear it comfortably all day, the design of intelligent wearable must overcome the foreign body feeling - small size, lightweight, and ergonomic shell. This means that intelligent wearable parts have the characteristics of small size, three-dimensional complex shape and special performance requirements.

Textile Embroidery

The application of MIM in industrial equipment can not be underestimated either. Various MIM tools and MIM locks used in our daily life can also be manufactured by metal injection molding machines. Its market is characterized by large-scale but scattered applications. MIM is widely used in industrial machinery, such as micro motor parts, electronic parts, sensor parts, cotton loosening machines, textile machines, sewing machines and so on.

Tools, Locks, Small Appliances

Electric tools also rely heavily on MIM. Considering the complicated machining, high processing cost and low material utilization rate of electric hand tool accessories, many applications have been developed in recent years, such as special-shaped milling cutter, cutting tools, fasteners, micro gear, cotton losing machine/textile machine/hemming machine, printer parts, magnetic core, striker pin, drive parts, etc.

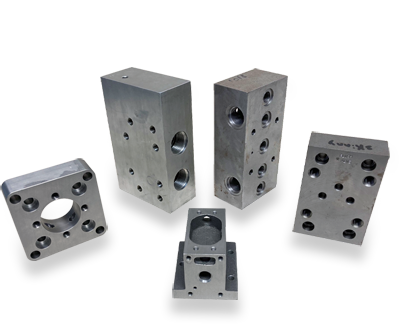

Accessories For Machinery And Equipment

The application of MIM in industrial equipment can not be underestimated either. Its market is characterized by large-scale but scattered applications. MIM is widely used in industrial machineries, such as micro motor parts, electronic parts, sensor parts, cotton loosening machines, textile machines, sewing machines and so on.

Military Police

MIM is capable of military and Police parts for use in a variety of industrial and consumer applications. Because MIM allows for high production volumes, the reduction or elimination of secondary machining, and a cost-effective price point, the technology is providing significant value for our customers.

Cell Phone

In China, smarts and 3C products are the biggest application fields of MIM. The rapid development of the mobile , communication and optical fiber industry has brought huge opportunities to the MIM industry. Most domestic MIM processing enterprises mainly make smarts, 3C products, and MIM metal injection molding parts. The parts of this industry require high precision and strong durability. The common products are: structural parts, connectors, special-shaped parts, mobile holder, slot, vibrator, etc.

Rotating Shaft

Since 2011, MIM, as the fifth generation metal forming technology, has been developing rapidly in mobile , automobile, medical, aerospace and other industries. In 2015-2018, there are countless MIM parts involved in consumer electronic s and computers. Nowadays, the hinge parts of the hinge of the core parts in the folding screen mobile also join the MIM tide, which makes MIM enterprises face new challenges and opportunities. 5g mobile market broke out, MIM injection molding technology is expected to be very colorful we all know, the feature of folding screen mobile is to double the screen size without greatly increasing the size of the device. In addition to the foldable and light design, the shaft of the intermediate core component should also have the characteristics of light, flexibility, thin and reliability. The hinge axis of the folding screen requires high precision and strength, and the complexity of structure and size are all in the advantage ra

Communication

Precision parts in the field of optical fiber base station communication, such as isolator cavity, optical fiber base, base station gearbox, etc., are better processed by powder metallurgy or traditional machining? Is it better to process fiber base, isolator cavity and base station gearbox by powder metallurgy or traditional machining? Through the above comparison, we found that the precision parts in the field of optical fiber communication are more complex, MIM powder metallurgy processing is more suitable for production, and the processing efficiency is higher, the mass production cost is lower, and the use of materials is more flexible.

Medical Treatment

JLY produces a variety of medical components through the MIM process, including endoscopic instruments, surgical instruments, and dental pliers. From design to production, we can assist in the complete manufacturing process and deliver value by creating near net shape components requiring little or no secondary operations.

Metal Powder

Material properties of MIM materialsMaterialChemical CompositionGeneral designationYield StrengthTensile StrengthHeat treatmentRange of applicationRemarksDensityElongationHardnessp(gr/cm3)Rp0.2Rm﹪HV10HV10...

Convert Traditional Manufacturing to MIM

|

Metal Injection Molding |

||||

|

Machining |

ColdForging |

LostWax |

DieCasting |

Powder |

|

Materialdifficultto machine |

Materialdifficultto forge |

Strength& toughness |

Hardness,strength, tougness |

Hardness,strength, tougness |

|

Complexshape |

Reducesecondary machining |

Reducesecondary machining |

Corrosion |

Welding |

|

Surfaceroughness |

Dimensional tolerance |

Dimensional tolerance |

Complexshape |

|

|

Surfaceroughness |

Surfaceroughness |

Surfaceroughness |

||

Economic Design Guidelines for MIM

Avoid thick design greater than 5 mm

Avoid long thin design

Avoid suspended design

Avoid skeleton design with extensive hollow features

As-sintered MIM is very economic but not as perfect as machined parts.

在线联系供应商

Other supplier products

| Clip Rail | Railroad Clip Steel MIM stand for metal injection molding china, it's a forming method of a metal parts and can provide a nearly unlimited shape, ... | |

| Small Hardware | Small Hardware MIMstand for Metal Injection Molding, it's a forming method of a metal parts and can provide a nearly unlimited shape, geometric-fe... | |

| Arrowhead | MIM stand for Metal Injection Molding, it's a forming method of a metal parts and can provide a nearly unlimited shape, geometric-feature capabilit... | |

| MIM Buckle | As one of theleading metal injection molding suppliersand metal injection molding companies,our business presence scatters in more than 30 countrie... | |

| Headset | MIM stand for metal injection molding china, it's a forming method of a metal parts and can provide a nearly unlimited shape, geometric-feature cap... |

Same products

| FOTON 12 TONS HOOKLIFT TRUCK | 卖方: Hubei Yuantai Special Automobile Co., Ltd | The hooklift garbage truckis a special sanitation vehicle modified on the basis of Foton brand ch... | |

| China High Quality OEM CNC Machining steel metal parts | 卖方: 深圳沃优达科技有限公司 | We are Ideal Group, specialized in custom machining with more than 15 years experience, with 150+... | |

| 浅蓝色涤纶织带 | 卖方: 浙江天台艾德旺斯纺织有限公司 | 型号 WB-004 材质:涤纶 常规宽度:20mm、25mm、32mm、38mm、50mm、100mm 包装:100米/卷 颜色:可定制 涤纶织带用途广泛,其独特性能使其适用于各种用途。它由涤... | |

| Felt Logo Patch | 卖方: Nanjing Jiamei Garment Accessory Factory | This is a patch with wool felt or Velcro base, silicone or rubber logo embossed. It is widely use... | |

| Reflective Labels | 卖方: Nanjing Jiamei Garment Accessory Factory | always appear on safety uniforms but now it is fashion lucky devil by brands. It not only helps t... |