Profound Tech provides the most advanced silicone rubber products manufacturing services.

Silicone is a kind of organic silicon compound, refers to the si-C bond, and at least one organic base is directly connected with the silicon atom compound, is also used to those by oxygen, sulfur, nitrogen, such as organic base and silicon atom connected to the compound as organic silicon compound. Among them, the polysiloxane is composed of silicon-oxygen bond (-Si-O-Si-) as the skeleton is the most in the number of organosilicon compounds, the deepest research, the most widely used, accounting for more than 90% of the total amount.

As one of the established silicone product manufacturer in China, Profound Tech provides the most advanced silicone rubber products manufacturing services, including oem silicone products, custom silicone products, liquid silicone products, and other special products such as high-temperature resistance (up to 330 degrees c), food-grade (fully comply with FDA, LFGB standard), medical-grade, flame retardant grade, by adding auxiliary raw material can also have, luminous, negative ions, discoloration, etc.

Types Of Silicone Rubber Products

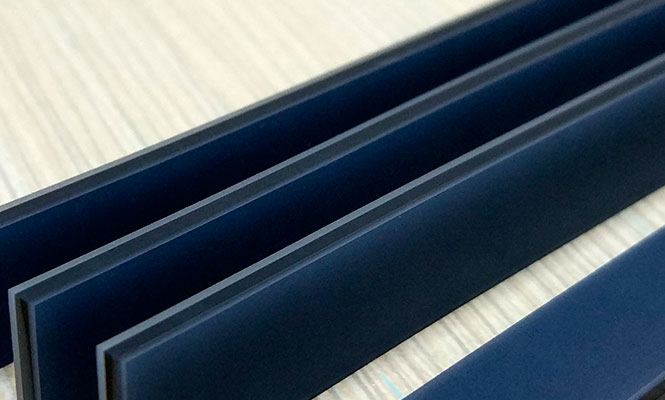

Zebra Connector

Zebra connector is mainly used to connect circuit board and display, widely and large amount of use, Profound provide a variety of sizes of zebra connector.

Silicone Keypad

Silicone keypad are often used in electronic calculators, remote controls, teles, wireless teles, electronic toys, computer keyboards, learning machine keys, cipher keys, digital product keys.

Silicone Eartips

Silicone eartips are widely used in ears. We have produced eartips for Apple Airpods/pro, Bose's QuietControl and many other ear manufacturers.

Silicone Thermal Pad

Silicone thermal pads are used for conducting heat in electronic products and circuit boards. For example, CPU, GPU, video memory, power supply, etc.

Silicone Rubber Parts

Silicone rubber has the characteristics of skid resistance, water resistance, shock absorption and high temperature resistance, so silicone rubber parts are widely used in industrial production, such as connectors, gaskets and sealing rings.

Silicone Toy/Tool

Fda approved food grade silicone rubber can be used in children's toys and kitchen utensils, it has high temperature resistance, corrosion resistance and other characteristics, is very popular in families.

Advantages of Silicone Rubber Products

Heat Resistance Properties

Silicone can not only withstand high temperature but also low temperature, can be used in a wide temperature range. Both chemical and physical-mechanical properties change very little with temperature.

Weather Resistance

Not easily decomposed by ultraviolet light and ozone. Silicone has better thermal stability and radiation resistance and weather resistance than other polymer materials. The service life of organic silicon in the natural environment can reach several decades.

Electrical Insulation Performance

Its dielectric loss, voltage resistance, arc resistance, corona resistance, volume resistivity and surface resistivity are among the best insulating materials, and their electrical performance is very little affected by temperature and frequency. Therefore, they are a stable electrical insulation material, which is widely used in electronic and electrical industries. In addition to excellent heat resistance, silicone also has excellent water repellency, which is the guarantee of high reliability for the use of electrical equipment under wet conditions.

Physiological Inertia

Polysiloxanes are among the least active compounds known. They are very resistant to biological aging, have no rejection reaction with animal body, and have good anticoagulant ability.

The Use of Silicone Rubber

Due to the organic silicon has these excellent performance, so it has a very wide range of application scope. It is not only used as special materials in aviation, cutting-edge technology, and military technology departments but also used in various sectors of the national economy. Its application scope has been expanded to construction, electronics and electricity, textile, automobile, machinery, leather and paper making, chemical and light industry, metal and paint, medicine and medical treatment, etc.

Key Properties of Silicone Rubber Products

The Viscosity

Proportional

Usually viscosity is proportional to hardness.

The Hardness

10~80 Shore A

Silicone rubber has a shore hardness range of 10 to 80, which gives the designer full freedom to choose the required hardness to best achieve a particular function.

Tensile Strength

4.0~12.5 MPa

The range of tensile strength of hot sulfur-added solid silicone rubber is 4.0-12.5mpa. Fluorosilicone rubber tensile strength range between 8.7-12.1MPa. The tensile strength of liquid silicone rubber ranges from 3.6-11.0mpa.

Tear Strength

9~55 kN/m

The tearing strength range of hot sulfur solid silicone rubber is between 9-55 kN/m. Fluorosilicone rubber tear strength range between 17.5-46.4kN /m. Liquid silicone rubber tear strength range between 11.5-52 kN/m.

Elongation

90~1120%

Thermal sulfurized solid silicone rubber generally has a range of elongation between 90 and 1120%. Fluorosilicone rubber generally has a elongation between 159 and 699%. Liquid silicone rubber generally has a elongation between 220 and 900%.

Operation Time

30 minutes ~ 48 hours

The colloid has been vulcanized from the moment of adding vulcanizer, the operation time is that the product 30 minutes of vulcanization reaction can not affect the quality of the finished product. Therefore, the more time saved during the operation of the product, the better for the finished product.

Curing Time

60~600 seconds

According to the production of temperature, pressure, curing time from 60 seconds to 10 minutes, different process to produce a product will be a slight difference.

OEM & ODM Silicone Rubber Products from Profound

As one of the most professional custom silicone manufacturers in China, Profound provides one-stop service. Mold design, mold production, product design, product production, quality control, packaging, shipping. We are strict in every link, to provide high quality service, production of quality products. Constantly optimize the product details, stand in the customer's point of view, reduce the cost of communication.

Profound is adept at spraying, laser carving and silk printing.

Profound has been specialized in the silicone rubber industry for over 20 years. We have extensive experience in the industry to help you solve your production problems. You just need to focus on the custom silicone products and don't have to worry about other things.

We are very happy to look into manufacturing difficult silicone rubber products, if other suppliers are not able to produce what you need, please give us a chance. Our slogan is: Do what others can't.

As one of the most professional silicone products suppliersin China, Profound providesoem silicone products, oem silicone parts, silicone products china, etc. For more information, please feel free to contact us!

在线联系供应商

Other supplier products

| Silicone Button With Oil Spraying | Silicone products are easy to absorb dust under normal circumstances, so in the production process, a thin layer of feel oil will be sprayed on the... | |

| Conductive Rubber Zebra Connector | Zebra conductive connectoris commonly known as conductive rubber connector, which is formed by alternating layer superposition of conductive and in... | |

| Silicone Toy/Tool | Silicone kitchenware is made of silicone products using food grade FDA, LFGB as the standard special silicone as the raw material, through molding ... | |

| Silicone Zebra Connector For Sale | Profound produces conductive silicone zebra connector, also known by the registered trademark ZEBRA connectors, and non-conductive (IR) rubber spac... | |

| Silicone Switch With PU Coating | PU is also a kind of ink commonly used by silicone products manufacturers, mainly used in some daily necessities, with strong adhesion, good wear r... |