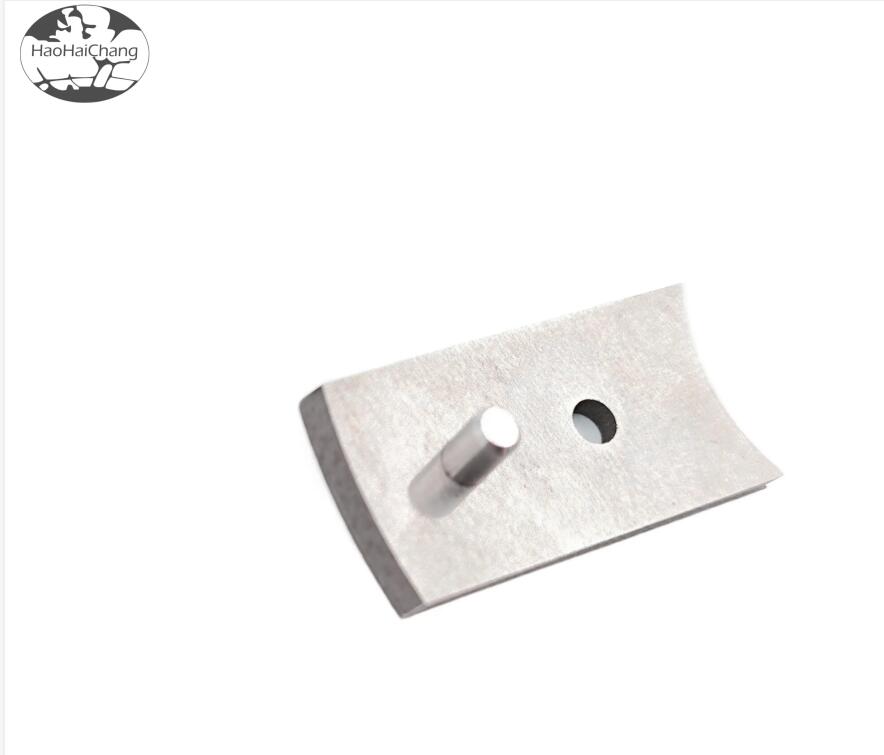

HHC-947 Die steel CNC Machining Parts

Material: Titanium alloy

Process: CNC Machining

Finish: Cleaning

Size: Custom

Related Other CNC Machining Parts

HHC-OCM-04 CNC Machining Parts

HHC-OCM-03 CNC Machining Parts

Why CNC Machine Copper Alloy?

Copper holds a significant position in the metal manufacturing industry and is widely used in the production of various metal components and products. Copper is not only utilized in its pure form but also in various alloy forms, such as brass (copper-zinc alloy), bronze (copper-tin alloy), and copper-nickel alloy, among others. These alloys possess different properties, including hardness, strength, and corrosion resistance, allowing for the selection of the appropriate copper alloy based on specific application requirements. The properties and parameters of copper and copper alloys are listed in the table below:

Due to its exceptional electrical conductivity, copper alloys are the ideal choice in electronic and electrical engineering. Using copper alloys in metal components ensures smooth electrical current conduction, reduces resistance, minimizes energy losses, and maintains circuit stability. This is particularly crucial in the manufacturing of wires, connectors, and electronic components.

Copper's outstanding thermal conductivity makes it a vital material in heat exchange equipment and radiators. Employing copper alloys in metal components aids in the rapid dispersion and transfer of heat, maintaining temperature stability, preventing overheating, and damage. This is especially critical in the production of equipment and products requiring effective heat dissipation.

Copper alloys exhibit good corrosion resistance, particularly against water and most chemicals. This makes copper alloys suitable for the manufacture of corrosion-resistant metal components, such as faucets, valves, and pipelines. In humid or corrosive environments, copper alloys can maintain their performance and appearance.

Copper and copper alloys are easily workable and possess good machining properties. This enables metal manufacturers to efficiently process and shape copper alloy parts, reducing production costs. Copper alloys can undergo various machining operations, including milling, drilling, cutting, and stamping.

Copper alloys offer diverse mechanical properties that can be tailored according to the alloy type to meet the requirements of different applications. This includes aspects such as strength, hardness, and wear resistance. Therefore, suitable copper alloys can be chosen to fulfill the mechanical performance needs of specific metal components.

Copper is a recyclable material, contributing to reduced resource waste and environmental impact. It aligns with the requirements of sustainable manufacturing and green production.

Custom CNC PartsApplications

Copper-produced metal products encompass a wide range, including copper expansion parts, copper flanges, copper brackets, copper busbars, copper clamps, copper springs, copper rivets, copper terminals, copper lathe parts, copper pins, copper screws, and more.

These products find applications in various industries, including the electronics sector, medical equipment industry, thermostat industry, household appliances sector, energy storage field, new energy sector, automotive industry, and more.

If you are looking for a reliable high precision machining supplier, please choose us, and we will be your best partner.

在线联系供应商

Other supplier products

| MEDICAL DEVICE ACCESSORIES | High Precision Parts are vital components in medical device accessories, where accuracy and reliability are crucial. These components, such as surg... | |

| DDP001 Stainless Steel Deep Drawing Parts | DDP001 Stainless Steel Deep Drawing ManufacturingParts Material: Stainless Steel Process: Deep Drawing Finish: Cleaning About DDP001 Stai... | |

| Carbon Steel Cold Headed Screw 01 | Material: Carbon Steel Process: Cold Headed Finish: Nickel Plating About Carbon Steel Cold Headed Screw 01 Carbon cold heading steelscrew... | |

| MEDICAL DEVICE ACCESSORIES | High Precision Parts are vital components in medical device accessories, where accuracy and reliability are crucial. These medical precision parts,... | |

| COLD HEADING | Cold heading partsare precision-engineered components made by deforming metal wire or rod at room temperature using a heading machine. The process ... |

Same products

| 20W PD Fast Charger | 卖方: Shenzhen Teng Da Xing Electronic Co., Ltd | 20W PD Fast Charger TheTDX 20W PD Fast Chargeris the ultimate solution for lightning-fast chargi... | |

| Interchangeable Plug Power Adapter-60W Series | 卖方: Shenzhen Teng Da Xing Electronic Co., Ltd | Interchangeable Plug Power Adapter-60W Series The60W interchangeable power adapteris AC to DC ad... | |

| Wall Mount Power Adapter-36W-9V 4A -Korean Plug | 卖方: Shenzhen Teng Da Xing Electronic Co., Ltd | Wall Mount Power Adapter-36W-9V 4A -Korean Plug Wall Mount Power AdapterSpecifications: Input v... | |

| 42W AC to DC Desktop Power Adapter | 卖方: Shenzhen Teng Da Xing Electronic Co., Ltd | 42W AC to DC Desktop Power Adapter High Efficiency, Broad Compatibility – Ideal for Indust... | |

| 90W Desktop Power Adapter | 卖方: Shenzhen Teng Da Xing Electronic Co., Ltd | 90W Desktop Power Adapter 90WDesktop Power Adapter– High efficiency, 94V-0 fireproof, DOE ... |