BMC/SMC Motor

BMC/SMC Electric MotorsDescription

Motor BMCreplaces traditional iron and aluminum, reduces the process, seals more, and has higher safety factor. It mainly refers to white goods and public motors. High insulation, chemical resistance, high fire resistance, good water resistance, accurate size, stable working performance, light weight, high strength, acid and alkali resistance, waterproof and moisture proof.

We provide you with the high-quality BMC electric motorand SMC electric motors.

BMC/SMC Motors Manufacturer

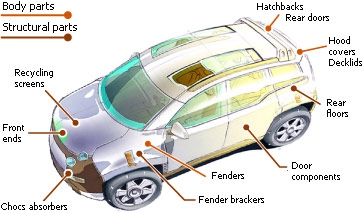

The motor range is wide, including: servo motor, plastic edging motor, plastic encapsulations product, BMC rotor, BMC stator, air conditioner motor, refrigerator motor, washing machine motor, DC motor, AC motor, automobile motor, power tool rotor, range hood motor, Motor end cap, motor bracket.

What is Bulk Molding Compound (BMC)

Bulk Molding Compound (BMC) is a thermosetting plastic material that is composed of polyester resin, fillers, and various additives. It is widely used in the production of electric motor components due to its excellent electrical insulation properties, mechanical strength, and dimensional stability. BMC is produced by blending the ingredients together, and then heating and compressing the mixture into a pre-designed mold. The mold is then cooled, and the hardened BMC moldingpart is removed.

What Are BMC Electric Motors

BMC electricalmotors are electric motors that use Bulk Molding Compound (BMC) as the material for their components. The use of BMC in electric motor production results in motors with high electrical insulation properties, mechanical strength, and dimensional stability. The material is particularly well-suited to the production of complex parts with thin walls, such as motor housings, end caps, and other components that require precise shapes and sizes. BMC electric motors are commonly used in a range of applications, including automotive, industrial, and household appliances.

Advantages of Using BMC in Electric Motor Production

There are several advantages of using BMC in electric motor production. Firstly, BMC has excellent electrical insulation properties, which makes it ideal for use in applications where electrical safety is a concern. Secondly, BMC has high mechanical strength, which means that it can withstand the stresses and strains of regular use without becoming damaged. Finally, BMC has excellent dimensional stability, which means that it can maintain its shape and size even when exposed to temperature and humidity fluctuations.

Advantages and Applications of SMC Motor

SMC motor offers several advantages over traditional electric motors, including:

Lightweight: SMC motor is made of composite material, which makes it lightweight and reduces the weight of the application it is used in.

High strength: SMC motor has a high strength-to-weight ratio, making it strong and durable.

High resistance to heat: SMC motor can withstand high temperatures, making it suitable for high-temperature applications.

SMC motor is used in various applications, including:

Automotive: SMC motor is used in electric vehicles, hybrid vehicles, and fuel cell vehicles due to its lightweight and high resistance to heat.

Aerospace: SMC motor is used in aircraft for its lightweight and high strength-to-weight ratio.

Industrial machinery: SMC motor is used in various industrial machinery due to its high resistance to heat and durability.

SMC Motor Manufacturing Process

SMC motor is manufactured through a process called compression molding, which involves:

Preparing the SMC material: SMC material is prepared by mixing chopped glass fibers, thermosetting resin, and other additives.

Placing the SMC material in a mold: The SMC material is placed in a mold that has the desired shape of the motor.

Applying heat and pressure: The mold is heated and pressure is applied to compress the SMC material into the desired shape.

Curing the material: The SMC material is cured by heating it to a high temperature for a specific period of time.

Finishing the motor: The finished motor is removed from the mold and any excess material is trimmed off.

The high-composite precision molds produced by Waiwai Tree have the characteristics of low energy consumption; our SMC and BMC molds have no waste, and there is no need to clear the inner cavity. Having only a small temperature difference, our SMC/BMC compositeshave stable mold temperature, good appearance, and high efficiency. Thus, they are now widely used in new energy vehicles, high-speed rail, and electric motors.

在线联系供应商

Other supplier products

| SMC Automotive Molding, Car Mould | Cars, buses, trucks, transport and special vehicles • Weight: Parts made from sheet molding compound (automotive smc) are typically 25-35%... | |

| SMC Antenna Reflector Mould | The satellite earth antenna is the important earth satellite equipment to collect the weak signal from satellite and reduce noise to the lowest lev... | |

| BMC/SMC Insulation | BMC Insulation High-strength, wear-resistant, fire-resistant, color BMC compositematerial for medium and low voltage insulators such as SMC Insu... | |

| BMC, SMC, GRP, GFK Roof Tiles | Aobang composite roofing tiles is divided into: BMC roofing tiles, SMC roofing tiles, GRP roofing tiles, GFK roofing tiles. Due to the excellent p... | |

| Household Mould | Household Mould Description SMC (sheet molding compound) materials are revolutionary materials in the sanitation industry. Household mouldis hel... |

Same products

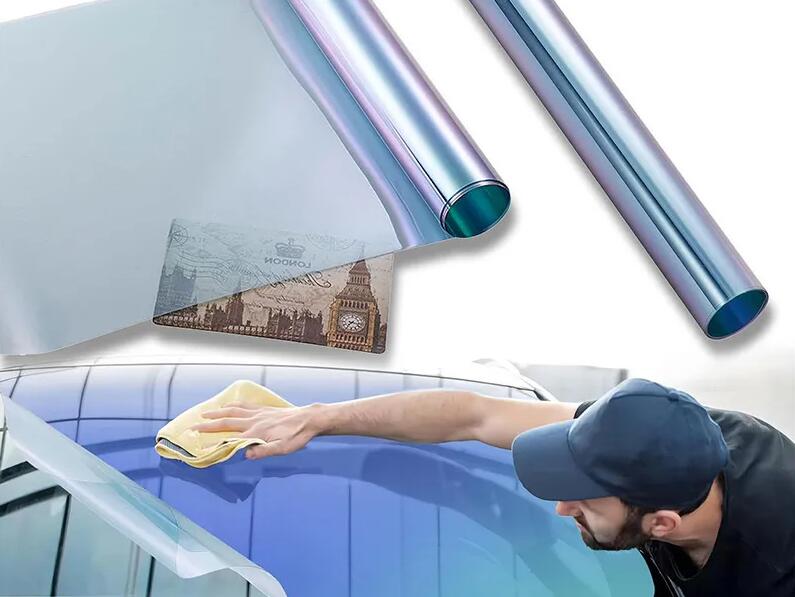

| Windshield FilmWindshield Film | 卖方: Beijing Kingfilm Advanced Material Co., Ltd | Windshield Film The automotive windshield film is installed on the outside of the windshield and ... | |

| Metallized Window Tint | 卖方: Beijing Kingfilm Advanced Material Co., Ltd | Metallized Window Tint The multi-layer magnetron sputtering double silver series has the charact... | |

| Matte PPF | 卖方: Beijing Kingfilm Advanced Material Co., Ltd | Matte PPF Mattepaint protection filmhas the beauty of a matte finish and a better natural light.... | |

| Textured Film | 卖方: Beijing Kingfilm Advanced Material Co., Ltd | Textured Film The TexturePaint Protection Filmsnot only has the texture of carbon fibre, but als... | |

| Customizable Electric Tonneau Cover | 卖方: Guangzhou Zhenlonghui Auto Accessories Co., Ltd. | Customizable Electric Tonneau Cover The advanced all-electric retractable Tonneau cover gives yo... |