LQ Series Rotor Pump Model B

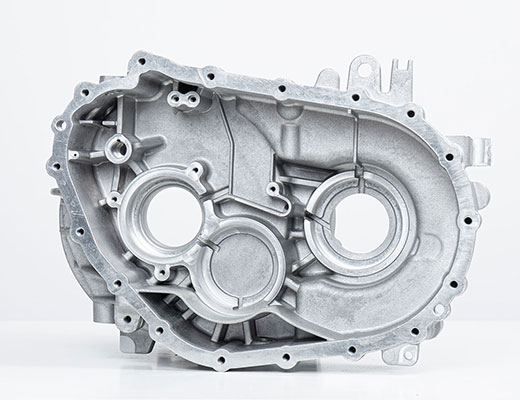

Product name:LQ series rotor pump (Model B )Product classification: rotor pumpProduct name: LQ series rotor pump (Model A )Product classification: rotor pumpFirst,Website:, product overview:LQ series of colloid pump - also known as roots pump, stainless steel rotor pump, lobe pump, universal conveying pump, yeast pump, butterfly pump, trefoil pump, sole pump, spice pump, hot melt colloid pump, particle colloid pump, slag material pump, protein residue pump, high consistency pump and so on. The suction force (vacuum degree) is generated at the inlet of the rotating process by two synchronous counter rotating rotors to inhale materials needed to be transported. Two rotors separate the rotor chamber into several small space and work according to the order of a b c d. When running to position a, only chamber I is filled with medium; when running to position b, chamber B closes partial media; when running to position c, chamber A also closes partial media; when running to position d, chamber A and B communicate with chamber II, and the medium is transported to the discharge month.Two, product features:1. All parts contacted with the media (material) are made of high quality stainless steel (material SUS304, AISI316, 316L), which are in full compliance with health standards.2. It is suitable for conveying high viscosity, concentration and any medium containing particles (materials).3. The suitable temperature is from -30°Cto 200° C.4. High pressure is suitable for transportation of long distance and high resistance quantitative.5. The rotational speed is low, which is generally between 200rpm to 600 rpm. Materials maintain the original quality after the delivery and can not afford any chemical reaction.6. There is no contact between rotors and no abrasion after long-term use with stable operation, low noise and high efficiency.7. It has novel design, easy installation and maintenance, convenient cleaning to ensure the cleaninside the machine and the production.Three, colloidal pump technical parametersProduct modelDaily transfer displacement (L)Recommended speed range (rpm)Corresponding flow rate(L)Motor power(Kw)Inlet and outlet pipeline path(mm)LQ3A-66200~500650~16000.75Ø25×1.5LQ3A-88850~21601.5Ø25×1.5LQ3A-12121300~32002.2Ø38×1.5LQ3A-20202100~54003Ø38×1.5LQ3A-3030200~4003200~64004Ø42×1.5LQ3A-36363800~76005.5Ø42×1.5LQ3A-52525600~11000Ø51×1.5LQ3A-66667100~140007.5Ø63.5×2LQ3A-78789000~18000Ø63.5×2LQ3A~2200011Ø76×2LQ3A~30000Ø89×2LQ3A~35000Ø89×2LQ3A~4300015Ø100×2Four, LQ series colloid pump applicationLQ series colloid pump has been carefully designed and developed by introducing, digesting and absorbing foreign advanced technology, compared with foreign similar pump, it has high accuracy, low cost, novel appearance and fills the gaps in the domestic and has been applied in various fields widely.First, it mainly has the following several points comparing with other pumps:a) This pump is a positive displacement pump, the flow rate can be controlled more precise and can also be easily made into variable pump. But the output flow of centrifugal pump cannot be controlled, which drops with the increase of resistance; This pump has a strong self absorption capacity, but the centrifugal pump must be filled with liquid before moving.b) The speed of the pump is very low, which is generally between 200rmp and 600rmp. The material transported is exported smoothly and its composition will not be damaged. But the speed of centrifugal pump is very high, the transported materials are effected by strong impact and centrifugal force, so the centrifugal pump has a frequent phenomenon of material composition in the delivery of the mixture, so that the quality of the finished product drops. The pump is the best choice to solve this problem, and it is particularly suitable for conveying the mixture and even materials containing solid particles. c) This pump can be used to transport a very high viscosity material, so also known as colloidal pump.. And the centrifugal pump has no this characteristic. d) This pump can be easily made into varieties outputting higher pressure, such as 15kgf/cm2, which is suitable for long-distance or high resistance quantitative transport.Second, comparing with screw pump (underflow pump) :Both the two pumps belong to positive displacement pump, so their performance is basically similar, which can stably transfer high viscosity material and have higher transportation pressure. However, there is a biggest disadvantages of screw pump which determines its inapplicability on occasions where there are health requirements, the non streamlined surface of screw pump and numerous defects in the chamber decide it cannot become a sanitary pump, cavity wall PTFE or rubber material damage is more likely to pollute the transported material. Due to rotor streamline structure without dead point or non metal parts in the rotor chamber, so strictly speaking, universal pump is more suitable for application in food and beverage and pharmaceutical industries of high sanitary requirements, especially the current automation degree of production line becomes higher and higher, also online (local) cleaning (CIP) is more and more adopted, which shows the importance of selecting colloid pump.Five, scope of application:Food industry: yogurt, fresh cream, ice cream, cheese, whey, beer, wort, yeast, soda, fruit juice concentrate, fruit drink, tomato sauce, fruit puree, vegetable paste, pudding, jam, jelly, flavoring agent, fruit filling, sweetener, yeast paste, salad sauce, bakeries, meat paste, ground meat, meat, oil, edible oil, candy, syrup, cream filling, chocolate etc.Daily chemical industry: face cream lotion, hair gel, hair dye, sesame oil, toothpaste, detergent, shampoo, shoe polish, cosmetics, shower gel, soap, balsam etc.Pharmaceutical industry: various types of pills, extract, emulsifier, syrup, nutrient solution, Chinese patent medicine, paste medicament, biological products, cod-liver oil, pollen, royal jelly, vaccine.Chemical industry: fat, solvent, resin and polymer, oil paint, pigment, dyestuff, paint, lubricating oil, grease, petroleum catalyst, emulsified asphalt, adhesive, detergent, plastics, explosive, glass steel, leather etc.Construction industry: all kinds of paints. Including interior and exterior wall coating, anticorrosion and waterproof coating, cold porcelain coating, colorful coating, ceramic glaze etc.Other industries: plastic industry, textile industry, paper industry, coal flotation agent, nano material, biochemical engineering etc.LQ series rotor pump (Instructions for use)ONE, Simplified diagram1. double row ball bearing 2. sealed mechanical pump 3. o-ring seal 4. pump cover 5. trefoil pump wheel 6. pump body 7. double-headed stud 8. bearing cover 9. bearing support 10. gear box 11. tapered roller bearings 12. drive shaft 13. main drive shaft 14. back cover of gear box 15. helical gear (pair) 16. oil seal17. o-ring seal Two, InstallationSince the pump has no electric motor, adjusting device or base plate and other accessories, the installation of the pump shall refer to below diagram (installation diagram) and the motor power and the highest speed in the technology parameter above to select appropriate motor (best selection is speed motor), model and a pair of flexible coupling, and to make a stainless steel base plate according to the center height of the pump and the selected motor.During installation, there are several issues which shall be paid attention to: First, the connection between the pump and the motor output shaft shall firstly be corrected level respectively to ensure that they are coaxial and then coupling can be installed, otherwise, the parts of the machine will be damaged.Second, because the pump is a constant volume pump and each turn has a fixed displacement, once upper procedures stop working for some reason, but the pump still continues to work, the pump pressure will rise infinitely, which finally leads to the occurrence of seal leakage , mechanical damage and other accidents. Therefore, it is necessary to take effective preventive measures. Example one: the upper and lower processes shall be chain, when the upper and lower processes stop, the pump shall stop working at the same time. Example two, safety valves and overpressure loop system can be installed in the output pipeline, once overpressure happens, unload will be done automatically.Third, the control valves can only be installed on the pump inlet pipe, the outlet pipeline shall not be installed control valves, which is easy to cause the failure of overpressure.After all installation is completed, comprehensive inspection shall be carried out, including parts solidation, electrical connection, etc. Then, turn the pump by hand for three to five circles, observe and check whether it gets stuck or loose until it is normal. Then carry out electric test run. If the pump is abnormal, it shall be stopped to be maintained. The pump can be used until everything is normal.Third, operation The pump operates conveniently and safely, as long as pressing the button and turning on electricity, it will begin to work normally. To ensure the well operation of the pump, the follows shall be paid attention to.First, before turning on the pump: first check whether the pump parts are intact and whether the valves on the inlet and outlet pipelines are all open. In a word, it is necessary to ensure parts are intact and pipelines are unblocked.Second, while turning on the pump: the equipment of the next step shall be started at first and then start the pump.Third, in the operation process, pay attention to whether the action is normal at any time. If there are the phenomena of cutoff in front of the pump and block behind the pump, the pump shall be timely stopped to solve the problems.Fourth, when the whole operation stops, the machine shall be stopped according to the process, that is to say, stop the pump first, then stop the related equipment behind the pump.For any mechanical equipment, the usual maintenance work does not only reflect whether the production is normal or not, what's more, but directly influences the service life of mechanical equipment. For pumps, of course, with no exception. Therefore, pay attention to the following maintenance work.First, the sealing parts, pump seal is divided into static seal and dynamic seal, the seal ring of static seal (see part 3 of Figure 1) shall pay attention to the surface which cannot have scratches or bumps, since scratches or bumps will directly affect the sealing effect. For the dynamic seal, because it will be affected by the pressure and the corrosion of transmission medium, the abrasion of medium particles and the influences of many other factors (see part 2 of Figure 1). Even the slightest mistakes are likely to cause leakage. Once leakage happens, the product shall be timely stopped and be cleaned by clean and soft cloth and then be painted with a layer of glycerin. After the manual assembly, the product can be starts. If the product cannot be repaired, new parts shall be replaced. Second, the lubricating conditions of the lubricating parts to the driving gear and rolling bearing of the pump shall be maintained (see part 15, 11 and 1 of Figure 1). Usually, often pay attention to the oil level height of gears, give enough lubricating oil to ensure the purity and cleanness of oil and replace new oil regularly (six months or a year). Third, the electrical system around electric equipment are not allowed to store equipment, material or gas which are damage to insulation. At the same time, electrical equipment shall work in the dry environment, otherwise, the moisture-proof facilities shall be prepared.Fourth, the daily maintenance, when machines do not work, appropriate cleaning agent shall be selected according to the nature of delivery materials to clean the pump effectively, finally rinse with clear water again to ensure the cleanliness of the pump.LQ series rotor pump (Outline dimension)Rotor pump installation, outline dimensionsProduct modelRLHH 1WW 1RemarksLQ3A-6Ø50.Interface connection mode: clamp, Screw thread, flangeLQ3A-8Ø50.LQ3A-12Ø50.LQ3A-20Ø50.LQ3A-30Ø63.LQ3A-36Ø63.LQ3A-52Ø77.LQ3A-66Ø77.LQ3A-78Ø77.LQ3A-100ØLQ3A-135ØLQ3A-160ØLQ3A-200ØNote:* The unit in this table is mm, the size of interface in the table is according to the end head diameter size which adopts quick-mounting clamp connection (the interface choices can also adopt interface form of screw thread fast loading, flanges etc. The specific dimensions of the inlet and outlet are omitted).* This product can be specially made according to the special requirements of users or instructions.* When products do not affect the improvement of basic structure and performance, notice will not given accordingly.LQ series of rotor pump (performance parameter)Product modelDaily transfer displacement(L)Recommended speed range(rpm)Corresponding flow rate (L)Motor power(Kw)Inlet and outlet pipelinepath(mm)LQ3A-66200~500650~16000.75Ø25×1.5LQ3A-88850~21601.5Ø25×1.5LQ3A-12121300~32002.2Ø38×1.5LQ3A-20202100~54003Ø38×1.5LQ3A-3030200~4003200~64004Ø42×1.5LQ3A-36363800~76005.5Ø42×1.5LQ3A-52525600~11000Ø51×1.5LQ3A-66667100~140007.5Ø63.5×2LQ3A-78789000~18000Ø63.5×2LQ3A~2200011Ø76×2LQ3A~30000Ø89×2LQ3A~35000Ø89×2LQ3A~4300015Ø100×2

Other supplier products

|

|

|

Product name: WQK / QG submerged sewage pump with cutting deviceProduct category: sewage pumpI. OverviewWQK / QG submerged sewage pump with cutting... |

|

|

|

Product name: MSP-18 type magnetic drive submersible pumpProduct Categories:Submersible pumpI. Features:Safe,Website:, reliable, low noise, corrosi... |

|

|

|

Product name: FZB series fluorine plastic self priming pumpProduct classification: self priming pumpFirst,Website:, product overview:FZB series of ... |

|

|

|

Production name: SPB glass molten jet pumpProduction Categories: hydraulic jetI. Production description:The glass fiber reinforced plastic injector... |

|

|

|

Product Name:XBD-W Horizontal Single-suction Multistage Segmental Type Fire Pump Product Category:Fire Pumpi.Product Description:XBD-W Horizontal S... |

供应产品

Same products