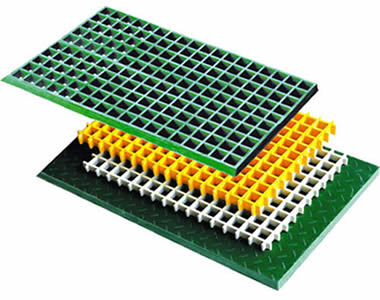

FRP Grating Platform

FRP Grating Platforms Ensure Workers' Safety

SARE Company's FRP gratings are ideal materials for operation platforms, including normal operation platforms, offshore oil platforms and tank deck platforms.

Thedimensions of FRP grating panelscan be found in the page of FRP gratings.

Operating platform:

Many chemical plants have a large number of operating platforms, and those which FRP gratings as surface materials are corrosion resistant, no paint, no maintenance with long service life of fifteen to twenty years. Its weight is three-quarters lighter than steel gratings, so there is no need of lifting equipment when installing. It is very easy to trepan and cut FRP gratings by arc cutting saw, and it won't lead to the change of mechanical properties or the scattering of grid, so as to meet the requirements of installation. In addition, the appropriate design making the FRP gratings have some elasticity, which can reduce the fatigue of workers who work over a long period of time. Therefore improve the work efficiency.

Using FRP gratings as the surface of platforms are corrosion resistant, and can reduce the fatigue of workers.

There is no need of lifting equipment when installing FRP gratings, and they are easy to cut into any sizes.

Offshore oil platform:

Traditional offshore oil platforms often use steel as surface material, but the bad weather and the sea erosion caused severe corrosion to these materials, which increase insecurity factors. Most foreign countries have successfully applied FRP gratings into this hostile environment. Due to the lightweight, the basic support components are easy to handle and the costs of platform are reduced through rational designation.

Offshore oil platforms made of FRP gratings can against the bad weather and the erosion of sea water.

FRP gratings as the material of offshore oil platforms could support a long time service in the hostile environment.

Tank top platform:

The roof walkways and tank deck platforms are always corroded seriously, and rust everywhere. Those rusty places often have accident potential, but FRP gratings could completely change this situation.

The FRP grating tank top platform can avoid rust and serious corrosion.

Using FRP gratings as the top platforms of tanks could resist the corrosion of liquid, so as to avoid accidents.

在线联系供应商

Other supplier products

| FRP Grating Stair Treads | FRP Grating Stair Treads Provide Safe Entry and Exit The production facilities of chemical plants and petrochemical plants always have several even... | |

| FRP Grating Water Treatment | FRP Gratings for Sewage Disposal FRP gratings for sewage disposal:SARE Company's FRP gratings can be used as paving material of cooling towers' ope... | |

| FRP Grating Shelves | FRP grating shelves for Corrosive Environment FRP grating shelves:There are lots of shelves in battery factories to store batteries, and use FRP gr... | |

| FRP Gratings | FRP Gratings with Light Weight but High Strength SARE Company'sFRP/GRP gratings(Fiberglass Reinforced Plastic Gratings) are interwoven from glass f... | |

| FRP Grating Fence | FRP Grating Fences Keep Workers Away From Danger Safety Fencesneed to be set around the high-pressure equipment and the bulk storage tanks, and bec... |

Same products

| Peptide Technology Cooperation & Transfer | 卖方: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

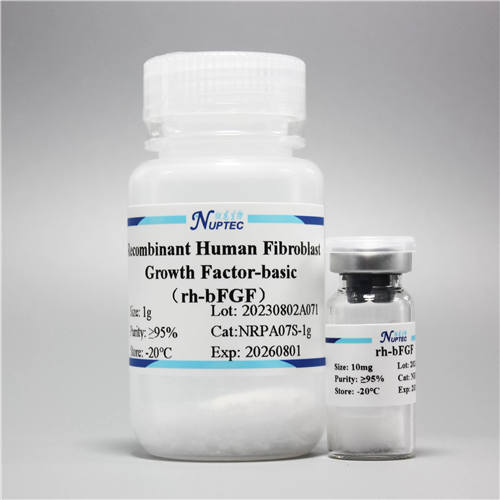

| Recombinant Human Fibroblast Growth Factor-basic | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

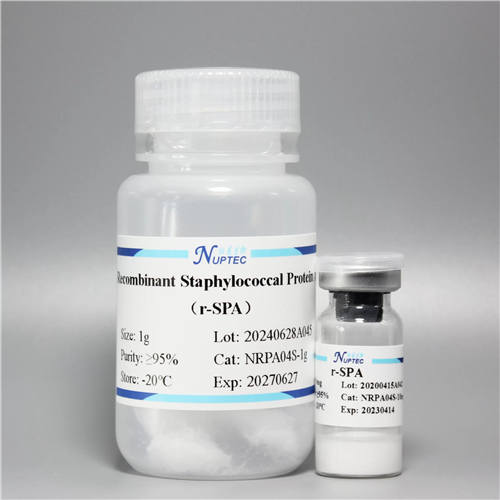

| Recombinant Staphylococcal Protein A | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |