Green Vs Black Silicon Carbide

Green Vs Black Silicon Carbide

Silicon carbide (SiC) is made of quartz sand, petroleum coke (or coal coke), wood chips, and other raw materials by a high-temperature smelting resistance furnace. In the contemporary C, N, B and other non-oxide high-tech refractory materials, silicon carbide is the most widely used, the most economic one, and can be called gold steel sand or refractory sand. At present, China's industrial production of silicon carbide is divided into black silicon carbide and green silicon carbide.

Main ingredients

The main chemical composition of silicon carbide is SiC, green silicon carbide contains more than 97% SiC, black silicon carbide contains more than 95% SiC.

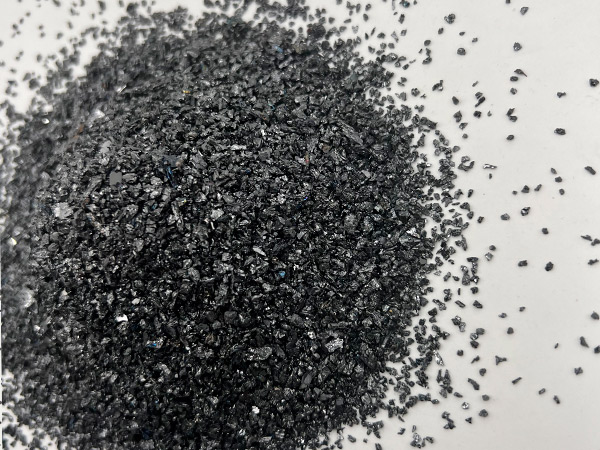

Colour And Luster About Silicon Carbide

Black silicon carbide is named black silicon carbide because of its black color.

Green silicon carbide is named green silicon carbide because of its green color.

Black silicon carbide is made of petroleum coke, quartz sand, wood chips, and other raw materials in the resistance furnace smelting.

Green silicon carbide in the production of raw materials and black silicon carbide production are roughly the same, as other industrial salt reaction agents and promoters in the resistance furnace reaction.

Texture And Application Of Black Silicon Carbide

Compared with corundum abrasive, black silicon carbide texture than corundum abrasive brittle, hard hardness, its toughness is also inferior to corundum abrasive. For tensile strength of the base material, such as non-metallic materials (all kinds of sheets such as wood plywood, particle board, including density fiberboard, bamboo board, calcium silicate board, leather, glass, ceramic, stone, etc.) and non-ferrous metals (aluminum, copper, lead, etc.) and other materials processing, is especially suitable for processing of hard and brittle materials is also ideal abrasive.

The texture of green silicon carbide grit is purer than black silicon carbide, hardness is higher than black silicon carbide, its grinding use and black silicon carbide is the same, more suitable for fine grinding materials such as grinding thread, grinding tools, etc., in the grinding material are more widely used in hard alloy, diamond products of the workpiece.

Because the cost of green silicon carbide in production is higher than that of black silicon carbide, such as the use of raw materials on the ratio is not the same, plus salt auxiliary materials and power consumption and processing process differences, so the price of green silicon carbide products is higher than that of black silicon carbide. Therefore, compared with black silicon carbide, generally do not choose green silicon carbide in non-metallic and non-ferrous metal materials, and mainly choose green silicon carbide as hard alloy and precision grinding, in the sand belt and other coated abrasives choose green silicon carbide as grinding material is less.

As one of abrasive material suppliers, we can offer kinds of abrasive raw materialsfor sale, if you are interested, please contact us.

在线联系供应商

Other supplier products

| Tabular Alumina | Tabular alumina powder for sale is a pure sintered α-alumina material. It is also known as white sintered alumina. Normally, the wholesale 1-... | |

| Zirconia Fused Alumina 40 | Zirconia fused alumina 40 is made of high-purity alumina and fused zirconia as raw materials. It is smelted at a high temperature of 2250 ° C a... | |

| Zirconia Fused Alumina | Zirconia fused aluminais made of alumina and zirconia as raw materials and is smelted at a high temperature above 2200 ℃ in an electric arc furnace... | |

| Boron Carbide | What is the formula for boron carbide Boron carbide powder for sale is a kind of gray-black micropowder. It is an inorganic substance. The chemica... | |

| Abrasive Garnet | As a naturally occuring silicate crystal, abrasive garnetis a great media for blast cleaning. The hardness of bulk abrasivo garnetis suitable for a... |

Same products

| Peptide Technology Cooperation & Transfer | 卖方: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

| Recombinant Human Fibroblast Growth Factor-basic | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

| Recombinant Staphylococcal Protein A | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |