Insulating Glass Molecular Sieve

zeolite insulationglass molecular sieve is the product to provide the insulating glass industry with the highest water capacity and lowest gas adsorption for solvent-free systems.

Parameters of Insulating Glass Molecular Sieve

|

Shpe |

Sphere |

|||

|

Diameter |

mm |

|||

|

Pore Volume |

Å |

3 |

3 |

3 |

|

Bulk density |

g/ml |

|||

|

Static water absorption |

% |

≥20.0 |

≥20.0 |

≥20.0 |

|

Crushing strength |

N/piece |

≥5 |

≥15 |

≥20 |

|

Dust (Turbidity meter) |

ppm |

≤30 |

≤30 |

≤30 |

|

Delta T (10 g /10ml) |

℃ |

≥38 |

≥38 |

≥38 |

|

Equilibrium N2 capacity |

% |

≤0.2 |

≤0.2 |

≤0.2 |

|

Dew point |

℃ |

<-73 |

<-73 |

<-73 |

|

Size ratio |

% |

≥98.0 |

≥98.0 |

≥98.0 |

|

Water content, as shipped |

% |

<1.5 |

<1.5 |

<1.5 |

Advantages of Insulating Glass Molecular Sieve

Very Selective Adsorption

Insulating glass molecular sieve material has been designed as a high water capacity adsorbent with the lowest capacity for air or other gases. The highly selective pore structure of assures excellent water dew point protection while eliminating the co-adsorption of gases in the sealed air space.

Low Deflection

Because insulating glass molecular sieve minimizes pick up of other gases, it reduces adsorbent contribution unit deflection and stress under severe climatic conditions.

Economy and Performance

Insulating glass molecular sieve increases gas-filled nit production rates since units can be sealed immediately after filling. In addition, the use of insulating glass molecular sieve maintains unit sound and heating insulation values by minimizing the adsorption of gases from the sealed space.

Homogeneous and Non-Separating

Unlike blends of two different desiccants that separate because of different component densities, insulating glass molecular sieve is homogeneous and uniform. Each bead is like every other. There’s no need to worry about unit-to-unit variation, which can occur with blends.

Residual Moisture

Insulating glass molecular sieve is supplied as a fully activated Insulating Glass Adsorbent, ready for use in spacer filling operations.

在线联系供应商

Other supplier products

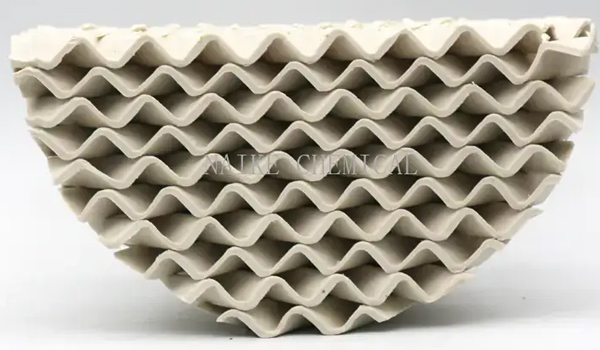

| CERAMIC STRUCTURED PACKING | Ceramic Structured Packing Ceramic structured packingis made up of many packing unit bodies that share the same geometry shape. Corrugated ceram... | |

| CERAMIC SADDLE PACKING | Ceramic Saddle Packing Description ceramic intalox saddleis divided into two different types of products according to their properties, one is o... | |

| ACTIVATED MOLECULAR SIEVE POWDER | Activated Molecular Sieve Powder Activated Molecular SievePowder is dehydrated synthetic powder molecular sieve. With the character of high disp... | |

| CASCADE RING PACKING | Cascade ringwas developed by MASS TRANSFER Inc. In the 1970s, improved from Pall Ring. The advantage of the Cascade ring is Large flux, low-pressur... | |

| Metal Pall Ring | Stainless steel pall ringsare an advancement on the Raschig Ring, with similar cylindrical dimensions but with two rows of punched out holes, with ... |

Same products

| Peptide Technology Cooperation & Transfer | 卖方: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

| Recombinant Human Fibroblast Growth Factor-basic | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

| Recombinant Staphylococcal Protein A | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |