Copper-Covered Ceramic Substrate Polishing Slurry

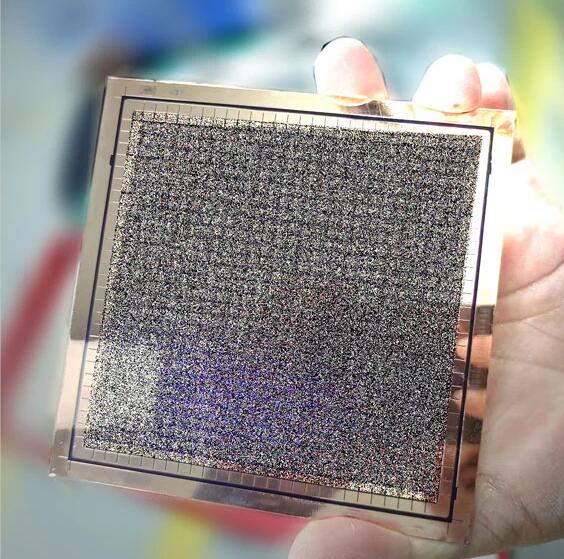

Copper is a good conductor. Resin substrates, metal substrates and ceramic substrates all need to be coated with copper to be used in electrical appliances. Ceramic substrate itself has good high temperature and corrosion resistance characteristics, after copper covered will be widely used in some high power electrical appliances and some high-end electrical appliances. The ceramic substrate coated with copper also needs to be polished to create a good surface.

Our Copper-Covered Ceramic Substrate polishing slurryprovides a mirror-like surface finish with no compromise on removal rate.

ALUMINA POLISHING SLURRY FOR COPPER-COVERED CERAMIC SUBSTRATE FEATURES

Copper-Covered Ceramic Substrate Polishing Slurry is developed for Copper-Covered Ceramic Substrate such as Copper-Clad ceramic substrate and Copper-Coated ceramic substrate.

According to the characteristics of copper material and high requirements of the PCB fabricate, it is a challenge to obtain mirror-like surface finish with no compromise on polishing rate.

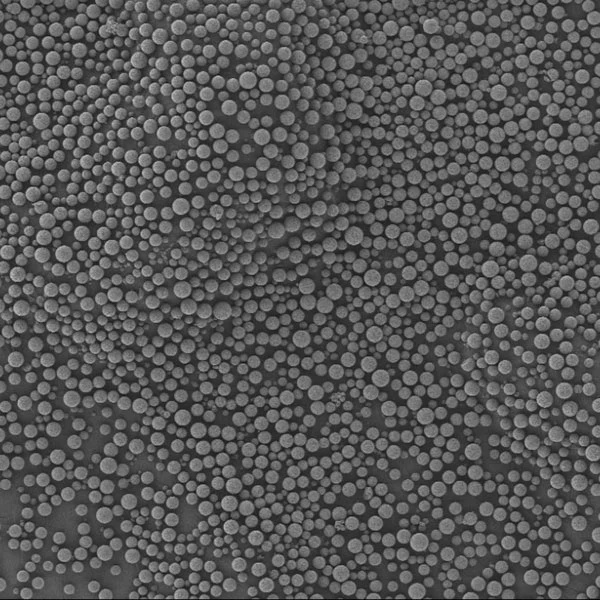

Kona nano alumina water-based polishing slurry for Copper-Covered Ceramic Substrate provides a good surface finish with no compromise on polishing rate.

ALUMINA POLISHING SLURRY FOR COPPER-COVERED CERAMIC SUBSTRATE ADVANTAGES

Alumina Polishing Slurry for Copper-Covered Ceramic Substrate Advantages

Kona offers a range of polishing slurry for Ceramic & Copper-Covered Ceramic Substrates.

Copper is a soft metal (Mohs hardness 3) , and it is a highly reactive metal and it oxidizes very easily. That increases the difficulty of polishing Copper-Covered Ceramic Substrate.

Our Copper-Covered Ceramic Substrate Polishing Slurry designed for Copper-Covered Ceramic Substrate polishing process, it is a water-based nano alumina polishing slurry added a additive special for the characteristic of copper.

Our Copper-Covered Ceramic Substrate Polishing Slurry provides a mirror-like surface finish with no compromise on removal rate.

For more informationabout alumina polishing suspension, please feel free to contact us!

在线联系供应商

Other supplier products

| Spherical Silica Powder | Spherical Silicon Oxide Powder Kona has developed spherical micronized silica powderfor high-performance applications, especially for cosmetic fil... | |

| Aluminum Alloy Polishing Slurry | Our alumina polishing slurryand colloidal silica used for aluminum alloy lapping and polishing, provide a fast removal rate and good flatness and f... | |

| Copper Polishing Slurry | According to the characteristics of copper material and high requirements of the 3C fabricate, Kona nano alumina water-based polishing slurry provi... | |

| Polishing Slurry for Alumina Ceramic | Alumina ceramics have high Mohs hardness, strong compressive capacity, high resistivity and good insulation, which are widely used in the manufactu... | |

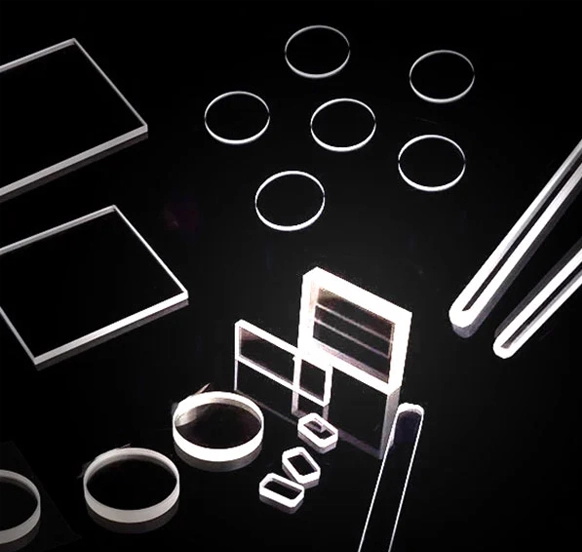

| Glass Polishing Slurry | We are one of the glass polishing powder manufacturersin China. Our goal is to provide our customers with high quality glass polishing powderto mee... |

Same products

| Peptide Technology Cooperation & Transfer | 卖方: PeptiOrigin Biotechnology Co., Ltd. | Peptide Technology Cooperation & Transfer Driving Innovation Through Strategic Partnerships ... | |

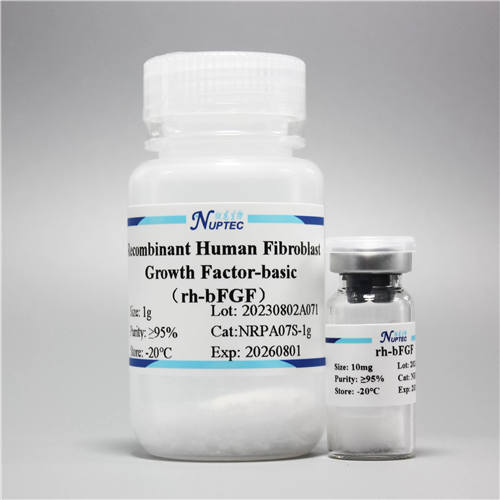

| Recombinant Human Fibroblast Growth Factor-basic | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Physical Appearance:Freeze-dried powder Formulation:5mMPB(pH7.4) before freeze-drying TheorypI:... | |

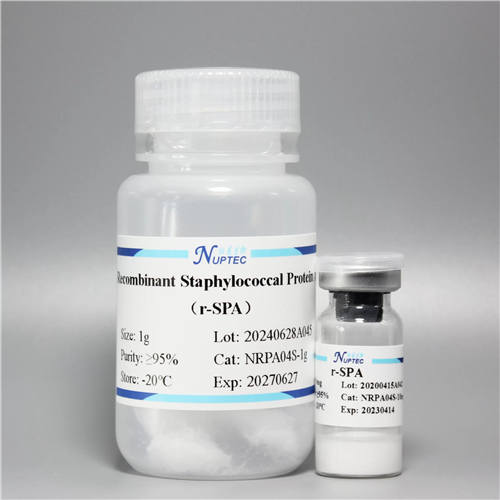

| Recombinant Staphylococcal Protein A | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | TheorypI:5.10 Resources:Escherichia coli(E. coli) Purity:≥95% Storage condition:-20℃ Stora... | |

| NuPerley Core 700 | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | NuPerley Core 700 Matrix:Rigid agarose microsphere Ligand:n-octylamine Particle size, d50:~90 ... | |

| Q NUPharose Fast Flow | 卖方: Hangzhou NeuroPeptide Biological Science and Technology Incorporation, Ltd | Matrix:6% Cross-linked agarose Ligand:Quaternary ammonium salt, -CH2CH(OH)CH2N(CH3)3+ Particle ... |