Wooden Carbide Brazing

JKZcan provide you a complete induction heating machine chinaexperience service. Our service staff will give customers a full response immediately,We can provide induction heating machine, industrial induction heating system, induction heating device, induction heating equipmentand so on,and meet the customer's various needs for equipment.

In the wooden cutters making process, it is necessary to combine the cutter head and the cutter body. Most of the time, induction brazing machine manufacturerswill use brazing to achieve the purpose of combination. As a mature induction brazing equipmentmanufacturer in China, JKZ has already independently developed a small solid-state high-frequency induction heating equipment (CX series) that is designed specifically for the tool induction heating brazing. The coils of this high frequency induction heater are designed according to the cutter hard alloy segments dimension. With the help of soldering material (usually copper, silver material which has a lower melting point than the hard alloy), our equipment can perfectly combine the segment and the cutter body together. With a power range from 7.5KW to 30KW, JKZ's CX series high-frequency induction heating equipment is very suitable for the brazing of various workpieces of different sizes. Capable of making power adjustment from 20% to 100%, it is the perfect choice to complete wooden tool welding. According to customer needs and actual conditions, CX series equipment has a very high-cost performance, and the rated power is enough to easily deal with most wood cutters brazing and repairing.This induction brazing applicationis very wide, and the induction brazing machine pricenow is relatively cheap.

在线联系供应商

Other supplier products

| Spring Heating | Coil springs or leaf springs are made by thermal deformation of steel profiles. Because of the characteristics of spring steel, there are certain r... | |

| High Frequency Induction Heating Machine | The working frequency of CX series ultra high frequency induction heating machinecovers 50KHZ ~ 120KHZ. You can find the existence of this high fre... | |

| SWP-HT 30KHz-60KHz Medium Frequency Induction Heating Machine | SWP series are JKZ's newly designed and manufactured induction heating power supplies. The HT version of SWP series equipment uses IGBT as the c... | |

| High Frequency Induction Heating Machine | The working frequency of CX series high frequency induction heating machine modulecovers 50KHZ ~ 120KHZ. You can find the existence of this high-fr... | |

| Induction Shrink Fitting | JKZcan provide you a complete induction heating machine chinaexperience service. Our service staff will give customers a full response immediately,... |

Same products

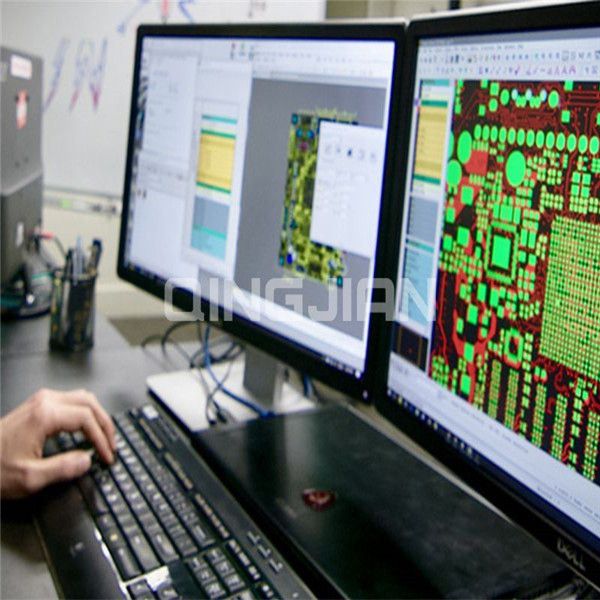

| PCB Assembly Service | 卖方: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB Assembly Service Product Description We have 5 SMT (Surface Mount Technology) production li... | |

| PCB design | 卖方: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB design Product Description We can provide various types of PCB board designand production, ... | |

| PHILIPS LED Strip HLS288 | 卖方: BMT LIGHTING | PHILIPS LED Strip HLS288 Plus 11.5W 4000K 30M IP20 Product date: Model Name:PHILIPS LED StripH... | |

| PHILIPS OEM LED Street Light | 卖方: BMT LIGHTING | PHILIPS OEM LED Street Light BMT-BST10D Heat Sink Outdoor Ip65 Waterproof 50w 120w 180w 240w Led ... | |

| PHILIPS Ultinon LED | 卖方: BMT LIGHTING | PHILIPS Ultinon LED Headlight bulb S25 12V 5W 11499ULWX2 BA15s Product description PHILIPS Ult... |