Game Controller Mold

To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, machining cost and time will be saved and the production efficiency increased. Green Vitality concerns a lot on mold cooling system and production stability. Our aim is to make customer run molds as less as possible for mold repair work, the best condition is free of repair work during mass production.

High-quality Game Controller Mold

To produce a high qualifed Gamepad mold, we need to work hard on mold design and analyze injection, ejection and cooling system, so that the gamepad is without flash, sinkmark, deformation and easy demoulding. These are very important factors when making gamepad mold and injection the parts. Some gamepad mold is textured on the surface, while some are glossy. Green Vitality has rich experience in making both textured molds and polished molds. Except mold building, we also provide injection molding, painting, printing, electroplating, ultrasonic welding, assembly service.

Basic Information for Game Controller Mould

Why Choose Us To Make Your Electronic Molds And Molding Parts?

Green Vitality offers a turnkey plastic molding solution from concept ideas to actual products. We make 3d printing, mold design, mold making, parts injection, surface treatment, and post-molding operation services.

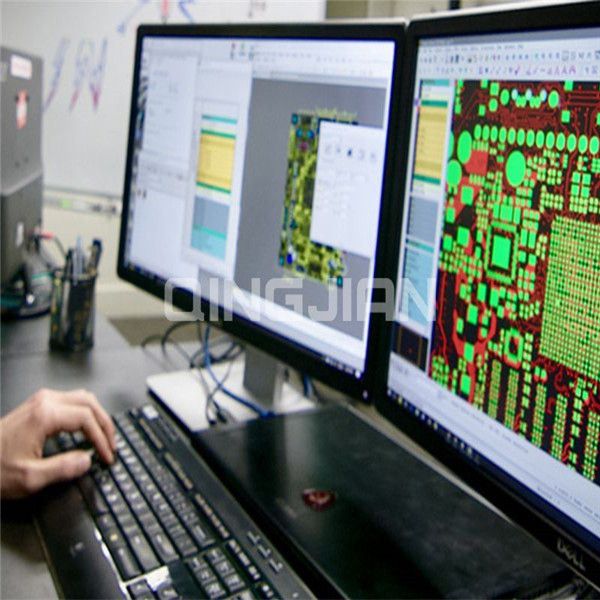

State of art mold processing and parts testing equipment.

Professional engineers, technicians, workers, sales, and after-sales teams.

ISO9001:2015 quality control system and modern Japanese management

24hours a day, 7days a week, two shifts working to meet your output demands.

25years experience in plastic injection mold and molding field.

Our motto is Quality is First, Customer is Frist.

Green Vitality Industry is a professional plastic injection factoryin various industries since 1993. We provide controller molds, video game controller mold, injection molds for sale, injection mouldingand etc. Want to know more, contact us.

在线联系供应商

Other supplier products

| Game Controller Mold | To increase the production efficiency, we need optimize the mold cooling system to shorten the cycle time. As a result, machining cost and time wil... | |

| Medical Plastic Injection Mold | Provide complete solutions from product design/mold manufacturing/injection mass production. Provide professional medical consumables and medica... | |

| Filter and Flow Limiting Apparatus | The family mold is used to produce injection parts for liquid filtration and flow monitoring and control systems. These accessories are custom... | |

| Car Light Mould | The car light mould plays a vital role in illuminating vehicles, serving as the eyes of cars. It encompasses all the lighting systems employed in a... | |

| Fan Mold | If the weight of each fan blade is not balanced, large vibration, high noise, and large wear of the rotating shaft will occur during high-speed rot... |

Same products

| PCB Assembly Service | 卖方: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB Assembly Service Product Description We have 5 SMT (Surface Mount Technology) production li... | |

| PCB design | 卖方: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB design Product Description We can provide various types of PCB board designand production, ... | |

| PHILIPS LED Strip HLS288 | 卖方: BMT LIGHTING | PHILIPS LED Strip HLS288 Plus 11.5W 4000K 30M IP20 Product date: Model Name:PHILIPS LED StripH... | |

| PHILIPS OEM LED Street Light | 卖方: BMT LIGHTING | PHILIPS OEM LED Street Light BMT-BST10D Heat Sink Outdoor Ip65 Waterproof 50w 120w 180w 240w Led ... | |

| PHILIPS Ultinon LED | 卖方: BMT LIGHTING | PHILIPS Ultinon LED Headlight bulb S25 12V 5W 11499ULWX2 BA15s Product description PHILIPS Ult... |