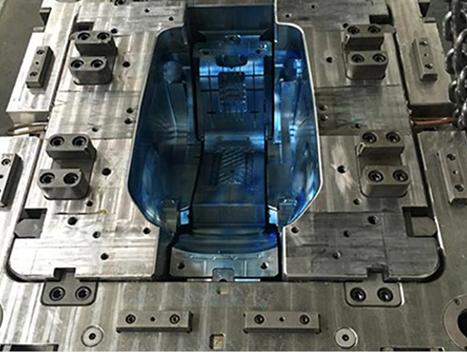

Keyboard Mould

Mainly electronic molds we make are electronic housing mold, electronic components mold, electronic dashboard cover mold, computer keyboard mold, computer mouse mold, bluetooth ear plastic mold, power bank enclosure mold, air purifier mold, plug plastic mold, gamepad mold etc.

The electronic plastic injection molding process is cost-effective and ideal for mass production runs and applications that require consistency and tight tolerances. Computer keyboard plastic inejction mold belongs to precision mold, Green Vitality has a team of professional and experienced engineer team to make high accuracy keyboard plastic mold for you.

High-quality Injection mold for Keyboard Mould

To produce a high-quality computer keyboard plastic injection mold, we need to work hard on mold design and analyze injection, ejection, and cooling systems, so that the keyboard is without flash, sink mark, deformation, and easy demolding. These are very important factors when making key cap moldand plastic parts. Our aim is once the injection parameter is set by our customers, the mass production will be continuously good, and no need to repair.

Design & Key Points For Computer Keyboard Mold

Computer keyboard steel:

Commonly used steel choices: 45#, 40Cr, P20, 2738, 2316, 718, 718H, NAK80, S136, 2316, 2738etc. Generally, 718 and NAK80 materials are used for computer keyboard molds, so that the surface of the product can achieve a certain smoothness, and the mold life is relatively long. If you want the mold quality to be more guaranteed, you can choose S136. We will advise customers to determine the mold steel according to the features of the product and customer requirements!

The key points of the computer keyboard mold:

The key point of computer keyboard mold injection molding is the selection of the gate, and its selection must ensure that the plastic filling pressure in the mold cavity is consistent and the pouring distance is the same. At the same time, we must know whether the temperature difference in different parts of the mold will affect the degree of melting of the plastic.

Green Vitality Industry is a professional plastic injection manufacturerin various industries since 1993. We provide keyboard key mold, keycap mould, custom plastic injection mold, plastic injectionand etc. Want to know more, contact us.

在线联系供应商

Other supplier products

| Keyboard Mould | Mainly electronic molds we make are electronic housing mold, electronic components mold, electronic dashboard cover mold, computer keyboard mold, c... | |

| Mouse Mold | One computer mouse usually includes these plastic parts: a bottom shell, an upper cover, a middle cover, a wheel, a base of wheel, a frame which co... | |

| Home Appliance Mould | Home Appliance Mould GV Mold has rich experience in home appliance mold(such as television, refrigerators, fans, washing machines, air conditi... | |

| Plastic Food Container Mould | Plastic meal boxes mainly used for packing foods, so it need to be heat resistant and non-toxic,and could meet the requirements of environmental pr... | |

| Auto Part Mold | Auto Part Mold With the vigorous development of the automotive industry, plastic auto part moldis also developing rapidly. 90% of auto parts are p... |

Same products

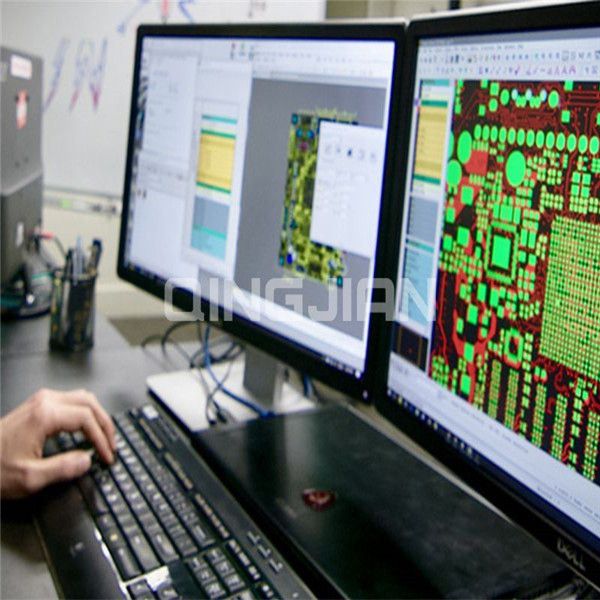

| PCB Assembly Service | 卖方: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB Assembly Service Product Description We have 5 SMT (Surface Mount Technology) production li... | |

| PCB design | 卖方: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB design Product Description We can provide various types of PCB board designand production, ... | |

| PHILIPS LED Strip HLS288 | 卖方: BMT LIGHTING | PHILIPS LED Strip HLS288 Plus 11.5W 4000K 30M IP20 Product date: Model Name:PHILIPS LED StripH... | |

| PHILIPS OEM LED Street Light | 卖方: BMT LIGHTING | PHILIPS OEM LED Street Light BMT-BST10D Heat Sink Outdoor Ip65 Waterproof 50w 120w 180w 240w Led ... | |

| PHILIPS Ultinon LED | 卖方: BMT LIGHTING | PHILIPS Ultinon LED Headlight bulb S25 12V 5W 11499ULWX2 BA15s Product description PHILIPS Ult... |