3 DIFFERENCES BETWEEN ANODIZING AND ELECTROPLATING

Electroplating uses the electroplating aluminummaterial as the cathode, which is the same as the electroplated metal as the anode. The electrolyte is a solution containing metal ions for electroplating, and an affirm current is input between the anode and the cathode. The plating material and the material to be plated are two different materials. For example, beryllium copper plate with nickel, beryllium copper is the substrate, and nickel is the plating layer.

Anodization uses chemical or electrochemical treatment to produce a thin film layer on the surface. The processed material acts as an anode, and when electricity is applied in a specific electrolyte, a thin film will be formed on the surface. If the aluminum alloy is oxidized, an aluminum oxide film will be formed on the surface of the workpiece. Alumina is chemically stable, will not be oxidated or corroded by acid, and can be dyed into various colours.

The objects processed by the electroplating method are mainly metal or non-metal. The most commonly used plating metals are nickel, chromium, tin, copper, silver, and gold. Often referred to as nickel plating, chrome plating, gold plating, etc.

Anodizing is a method of metal surface treatment. Most metal materials (such as stainless steel, zinc alloy, aluminum alloy, magnesium alloy, copper alloy, titanium alloy) can be anodizing in a suitable electrolyte.

Electroplating uses the electroplating material as the cathode. Anodizing uses the material to process as the anode.

Electroplating is due to the charge effect, the metal anode ions move to the cathode, where the electrons deposit on the material to the plating. At the same time, the metal in the anode dissolves, constantly replenishing the metal ions in the electrolyte.

Anodizing is the use of easy-to-oxidize aluminum alloys to control the formation of oxide layers through electrochemical methods. Prevent further oxidation of aluminum and increase the mechanical properties of the surface.

Anodizing technology is currently the broadest and most successful technology. Anodized aluminum alloy can improve surface hardness and wear resistance.

There are a lot of micropores in the thin oxide film, which can absorb various lubricating oils and is suitable for manufacturing engine cylinders or other wear-resistant parts. The film has a strong adsorption capacity and can be dyed into various beautiful colors. Non-ferrous metals or their alloys can be anodized. This method is widely used in mechanical parts, aircraft and automobile parts, precision instruments and radio equipment, daily necessities, and architectural decoration.

As a professional aluminium die casting parts manufacturer, EMP Techhas high-quality casting parts for sale. Welcome to contact us if needed.

在线联系供应商

Other supplier products

| WATER PUMP HOUSING | Overview of Water Pump Housing There is a multiple cooling circulation pipe connected to the radiator in the front of the automobile, which constit... | |

| GAS CAR PARTS | Aluminum die castings can be used in wiper systems, engine systems, filter systems, air conditioning systems, precision compressor parts, shock abs... | |

| ENGINE OIL PAN | Engine Oil Pan The oil panis an important part of automobile engine and an indispensable part of engine lubrication system.By sealing the lowe... | |

| PUMP & VALVE PARTS | EMP Techis a global, full-service manufacturer of china aluminum die castingproducts. With more than 20 years' experience in research & develop... | |

| CNC MACHINING | EMP Techis a global, full-service aluminum die casting manufacturer china. With more than 20 years' experience in research & development, manuf... |

Same products

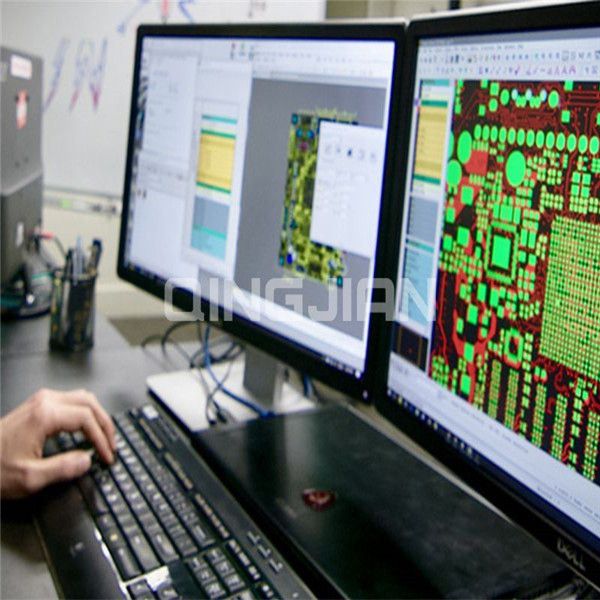

| PCB Assembly Service | 卖方: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB Assembly Service Product Description We have 5 SMT (Surface Mount Technology) production li... | |

| PCB design | 卖方: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB design Product Description We can provide various types of PCB board designand production, ... | |

| PHILIPS LED Strip HLS288 | 卖方: BMT LIGHTING | PHILIPS LED Strip HLS288 Plus 11.5W 4000K 30M IP20 Product date: Model Name:PHILIPS LED StripH... | |

| PHILIPS OEM LED Street Light | 卖方: BMT LIGHTING | PHILIPS OEM LED Street Light BMT-BST10D Heat Sink Outdoor Ip65 Waterproof 50w 120w 180w 240w Led ... | |

| PHILIPS Ultinon LED | 卖方: BMT LIGHTING | PHILIPS Ultinon LED Headlight bulb S25 12V 5W 11499ULWX2 BA15s Product description PHILIPS Ult... |