FOOD STEAMER STAINLESS STEEL BELT PRODUCTION LINE

FOOD STEAMER STAINLESS STEEL BELT PRODUCTION LINE

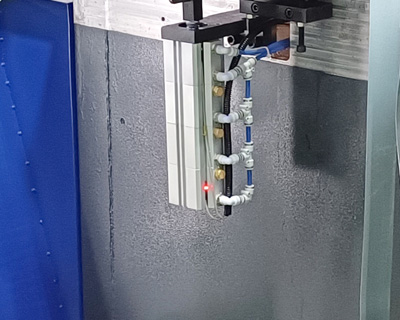

This equipment is specially customized for the steamer industry, and realizes the automatic production of welding and forming of stainless steel strips for steamer. The equipment adopts advanced laser continuous welding technology, and the overall operation is simple. Using touch screen to control the technical parameters of the equipment, it can automatically complete multiple processes such as feeding, cutting, welding, crimping, unloading, etc. The width of the steel strip can be adjusted freely without changing the mold. The equipment can achieve seamless welding and achieve the best material saving effect.

THE PARAMETER OF FOOD STEAMER STAINLESS STEEL BELT PRODUCTION LINE

|

Rated total power |

Input voltage |

Enter the frequency |

Product diameter |

Product thickness |

Product width |

Dimensions |

|

25KW |

3*380V |

50HZ |

120~600mm |

<0.7mm |

25~118mm |

2800*1700*2100mm |

The Application Of Food Steamer Stainless Steel Belt Production Line

The equipment is suitable for the production of steamer stainless steel strip welding and forming, and the equipment adopts laser welding. Suitable for producing stainless steel rings of various widths, thicknesses and diameters. Automatic crimping process by conveyor belt after welding. For laser seamless welding, various production problems such as weak welds, uneven welds, unsightly welds, and waste of materials are solved.

The Advantages Of Food Steamer Stainless Steel Belt Production Line

The device is highly efficient. Using high-precision servo motor feeding and high-speed start-up clamping and pushing device, it can achieve precise cutting and welding of steel strips. High quality. The equipment is highly energy-saving, and has the function of automatic shutdown after no material and material jam. The surface of the welded product is smooth and beautiful without burrs, and the desoldering rate is less than 0.1%.

Other Notes Of Food Steamer Stainless Steel Belt Production Line

Food Steamer stainless steel belt production line Main Characteristics

1

Arbitrary adjustment, the equipment is controlled by the program, and the welding size can be adjusted arbitrarily.

2

The operation is simple and fully numerically controlled, and every worker can operate the equipment after learning.

3

High energy saving, the equipment has the alarm system of no material and material jam, and the function of automatic shutdown.

4

High-quality, laser continuous welding makes the welds meet the highest requirements.

5

High efficiency, high-precision servo system is used to start various processing steps at high speed.

6

Low cost, the equipment combines multiple processes to complete, which completely solves the labor problem.

Now the price of stainless steel argon welding machineis reasonable, if you have needs, please contact us.

As one of laser welding machine manufacturers, we will do our best to meet all the needs of customers.

在线联系供应商

Other supplier products

| AUTOMATION EQUIPMENT FOR AUTO PARTS INDUSTRY | For the auto parts industry, we have independently developed welding equipment such as brake shoe seam welding machine, fillet welding machine, plu... | |

| DOUBLE RIB BRAKE SHOE ANGLE WELDING MACHINE | DOUBLE RIB BRAKE SHOE ANGLE WELDING MACHINE It is suitable for the positioning and welding of the welding seam at the outer corner formed by the d... | |

| PAPER DRUM STAINLESS STEEL BELT LASER WELDER | PAPER DRUM STAINLESS STEEL BELT LASER WELDER The equipment is mainly aimed at the stainless steel of the paper drum, which is made of galvanized m... | |

| DUST COVER WELDING MACHINE | DUST COVER WELDING MACHINE The Dust Cover Welding Machine is a machine designed to make covers for welding machines. The machine uses a welding pr... | |

| FOOD STEAMER STAINLESS STEEL BELT PRODUCTION LINE | This equipment is specially customized for the steamer industry, and realizes the automatic production of welding and forming of stainless steel st... |

Same products

| PCB Assembly Service | 卖方: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB Assembly Service Product Description We have 5 SMT (Surface Mount Technology) production li... | |

| PCB design | 卖方: Shenzhen Qingjian Electronic Technology Co., Ltd | PCB design Product Description We can provide various types of PCB board designand production, ... | |

| PHILIPS LED Strip HLS288 | 卖方: BMT LIGHTING | PHILIPS LED Strip HLS288 Plus 11.5W 4000K 30M IP20 Product date: Model Name:PHILIPS LED StripH... | |

| PHILIPS OEM LED Street Light | 卖方: BMT LIGHTING | PHILIPS OEM LED Street Light BMT-BST10D Heat Sink Outdoor Ip65 Waterproof 50w 120w 180w 240w Led ... | |

| PHILIPS Ultinon LED | 卖方: BMT LIGHTING | PHILIPS Ultinon LED Headlight bulb S25 12V 5W 11499ULWX2 BA15s Product description PHILIPS Ult... |