Robotphoenix Wafer Handling Robot

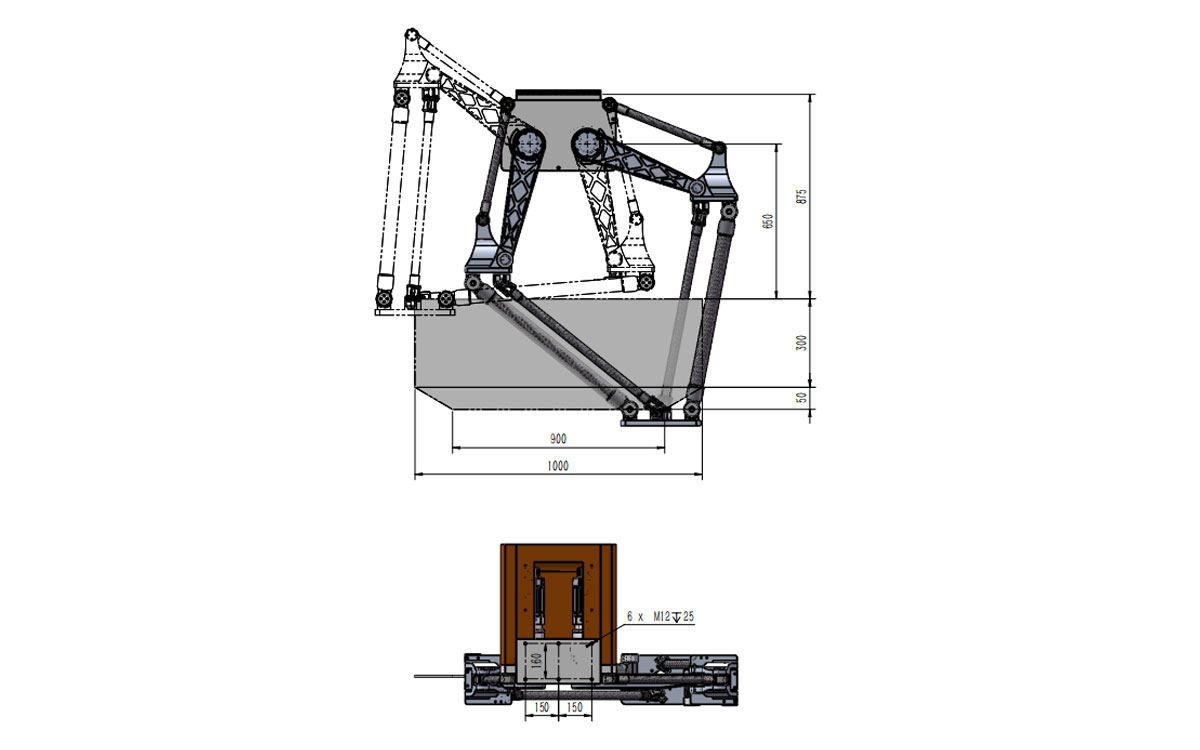

Based on the pioneering technology of intelligent high-speed parallel delta robot, Robotphoenix invented new 4-DOF parallel semiconductor wafer handling robots of single-platform and dual-platform, which broke through the bottleneck to realize a larger swing angle and higher output speed in multi-closed-loop parallel mechanism. The dual-platform robot angle can reach at least ±180°, and under 0.1kg payload, the fastest travel beat of running in the standard doorframe-shaped trajectory can reach 0.28s. Maximum acceleration is 15g.

Wafer Handling Robot Types

Lobster200Z300S-T0X5-C Wafer Robot

One-armed robot; arm length 200mm;

Payload 0.5kg;

Repositioning accuracy ±0.1mm. Its cleanliness reaches class 100, suitable for atmospheric applications.

Lobster185Z340D-T2X0-C Wafer Robot

Two-armed robot; arm length 185mm;

Payload 2kg;

Repositioning accuracy ±0.1mm. Its cleanliness reaches class 100, suitable for atmospheric applications.

Lobster200Z300S-T0X5-V Wafer Robot

One-armed robot; arm length 200mm;

Payload 0.5kg;

Repositioning accuracy ±0.1mm. Its cleanliness reaches ISO Class1, suitable in a vacuum environment.

Wafer Handling Robot for Specific Environmental Demands

Atmospheric wafer handling robots

Lobster200Z300S-TOX5-C one-armed wafer handling robot and Lobster185Z340D-T2XO-C two-armed wafer transfer robot are suitable for atmospheric applications.

Vacuum-compatible wafer handling robot

Lobster200Z300S-TOX5-V one-armed wafer handling robot fits in a vacuum environment.

Features of Wafer Handling Robot

The automated wafer handling automationrobot self-developed by Robotphoenix achieves a repositioning accuracy of 3μm, which reaches higher accuracy compared to other similar products of approximately 20μm. The Lobster series wafer handling robots are a type of industrial robots for sale that include single-armed, double-armed, and vacuumed models, and can be used in various semiconductor wafer handling scenarios.

Wafer Handling Robot Video Library

Industry Applications of Wafer Handling Systems

Wafer robots find essential roles in various industries:

Semiconductor Manufacturing: Ensuring flawless wafer transfers, and optimizing yields.

Electronics Assembly: Enabling precision in microelectronic device creation.

Photovoltaic Production: Enhancing solar panel quality and consistency.

Optoelectronics: Enabling precise handling for advanced optics.

Biotechnology and Medical Devices: Aiding in delicate component fabrication.

MEMS (Micro-Electro-Mechanical Systems): Precision handling for small-scale devices.

Advanced Packaging: Accurate placement in multi-die packages.

Research and Development: Supporting material and process experimentation.

These applications highlight the wafer robot's impact across industries, fostering efficiency and innovation.

Why Choose Semiconductor Wafer Handling RobotsFrom Robotphoenix?

Founded in 2012, Robotphoenix is a national high-tech robotic machinery enterprise integrating R&D and manufacturing of industrial robots, development of control systems and vision systems, intelligent manufacturing solutions, and equipment provision. Robotphoenix has passed various management system certifications and holds more than 200 national patents, obtaining self-support exports and import rights. We have developed and completed over 900 application cases in industries such as automobiles, 3C electronics, food, daily chemicals, healthcare, logistics, and new energy, and have been awarded honorary titles such as national-level specialized, refined, and innovative 'Small Giant' Enterprise; and Provincial Manufacturing Single Champion Enterprise.

Silicon Wafer Handling - Top Of Semiconductor Wafer Handling Robots

Lobster-series automated wafer handlingrobot consists of the robot body and end effector (optional), with excellent structural rigidity, equipped with a high-performance RP-Lobster series controller system, achieving smooth and fast handling process by highly manipulative servo motor and control software. It has extremely high accuracy, flexibility, and safety, with a repositioning accuracy of no more than ±0.1mm., which can be used for precise transportation and transmission of processed components.

在线联系供应商

Other supplier products

| BAT1000B-S60 Heavy Load Delta Robot | BAT1100B-E60 delta robot is a 2-axis parallel robot with a rated payload of 60kg, which has the characteristics of high speed and precision, small ... | |

| Mantis1000-A7 6-Axis Robot | Mantis series 1000-A7 robot six axishas a rated payload of 7kg. The robot has six axis and it is developed for complex applications with multiple d... | |

| 2-Axis Delta Robot from Robotphoenix | BAT-B parallel delta robot is also called two axis robot armor delta robot 2-axis. It is a small high-speed industrial robot widely used in graspin... | |

| 6-Axis Collaborative Robot | Robotphoenix- Leading 6 Axis Robot Manufacturer The self-developed Mantis series six-axis robot is designed for complex applications which require... | |

| Robotphoenix 3-Axis Robot | The classic high-speed parallel Bat-C delta robot is a sort of three axis robot, and its configuration is characterized by translational motion alo... |

Same products

| MTUB43-90511B-12A20 Mini USB Female Connector | 卖方: MTCONN ELECTRONICS CO.,LTD | This model is a Mini USB R/A T/H DIP female connectorthat complied with RoHS certificate. It adop... | |

| Radar RD03 | 卖方: Xi'an Interwiser Electronic Technology Co., Ltd | The RD03 low-altitude surveillance radaris a Ku-band phased array radar that adopts an all-solid-... | |

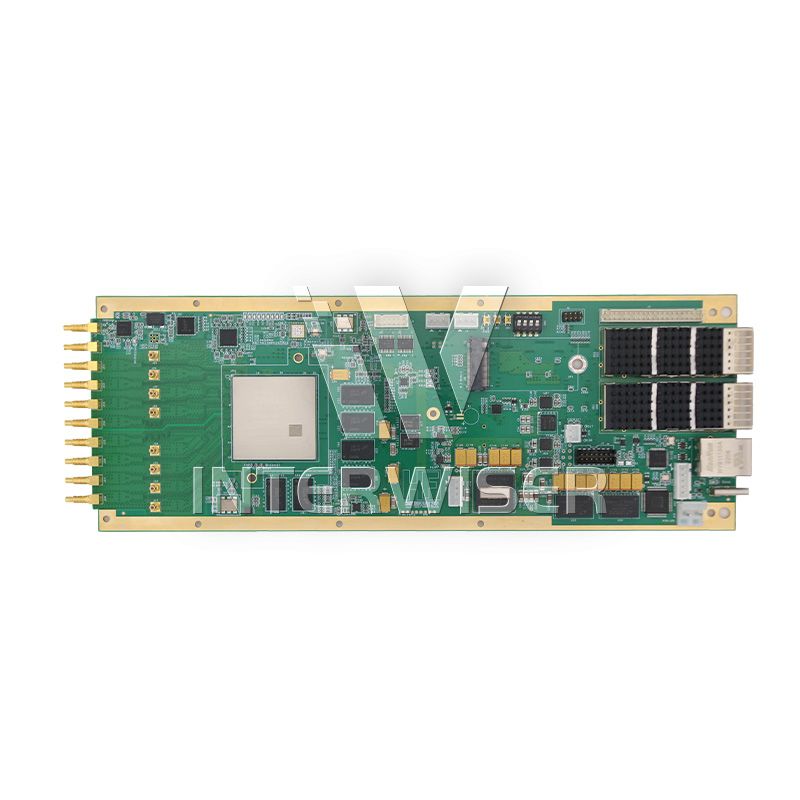

| IWRFSOC8X8 Xilinx RFSoC 3U 4-Channel/ DC-4GHz | 卖方: Xi'an Interwiser Electronic Technology Co., Ltd | InterWiser IWRFSOC8x8 3U algorithm evaluation modular systemdesigned for integration into deploye... | |

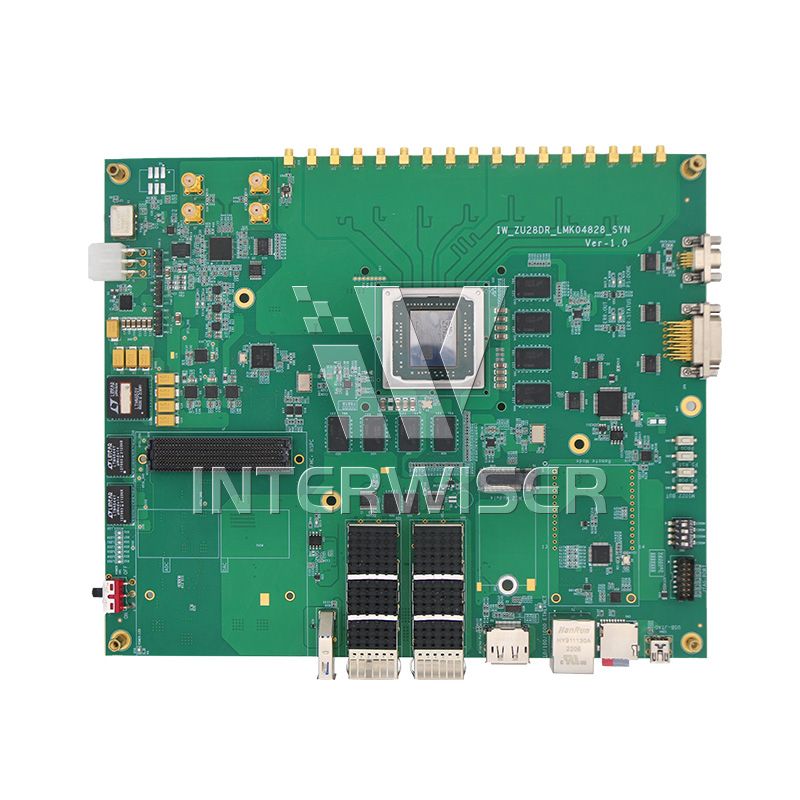

| IW-RFSOC-48DR-SYN Mixed Signal Processing Card | 卖方: Xi'an Interwiser Electronic Technology Co., Ltd | IW-RFSOC-48DR-SYN digital-analog mixed signal processing card, using Xilinx ZYNQ UltraScale + RFS... | |

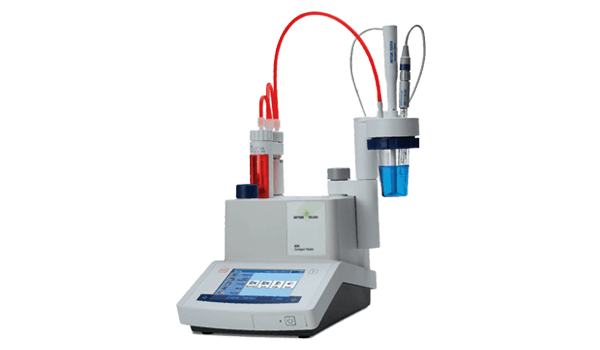

| all kinds of Analytical Instruments | 卖方: O&K GROUP LIMITED | Okwishing供应各类分析仪器。 Okwishing()是一个跨境电商平台,致力于为全球消费者提供有效、优质的分析仪器产品。 基于中国分析仪器产业链供应能力,我们汇集了多样化的分析仪器类别... |