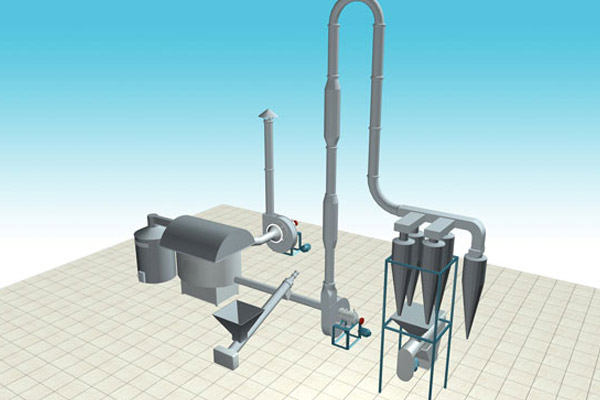

Airflow Flash Dryer(Cassava Drying Machine)

Features of Airflow Flash Dryer(Cassava Drying Machine)

The starch factory at present normally adopt airflow drying (also called flash dryingor flash dryer for cassava flour), the whole process time is completed in an instant, so the internal moisture of the starch granules have been dry before gelatinization, the pasting or degradation phenomenon will not occur. Airflow drying is concurrent flow drying process, namely, the concurrent flow of wet powder material and the heat flow, consists of heat transfer and mass transfer process. When wet starch with the hot air in contact, hot air transfer heat to the surface of the wet starch, again from surface to interior, the process is the heat transfer process; At the same time, the moisture in wet starch diffusion from the material inside to the surface of starch by liquid or gaseous, and the diffusion into the hot air from the starch surface through the gas film, it is a mass transfer process. By the high-temperature air and wet starch balanced heat exchanging in the drying tube, the drying starch become dry powder, and then packing and warehousing after cooling.

Processing Capacity: 100-2000Kgs/hour

Application Scope: Cassava starch and flour drying

Product Introduction: Airflow flash dryer, cassava starch drying machine, cassava flour drying machine for cassava starch and flour processing. So it can be also called cassava flash dryer.

Product Application of Airflow Flash Dryer

Widely used for the drying in starch, modified starch, medicine, food, chemical industry etc particle materials.

Technical Parameters of Airflow Flash Dryer

|

Modelnumber |

Outputyield |

Power |

Voltage |

Finalwatercontent |

Material |

Coverarea |

|

GD-HG-300 |

300kg/hour |

13kw |

380V/50Hz |

≤13% |

Stainlesssteel |

30-40m2 |

|

GD-HG-500 |

500kg/hour |

22kw |

380V/50Hz |

≤13% |

Stainlesssteel |

30-40m2 |

|

GD-HG-1000 |

1000kg/hour |

30kw |

380V/50Hz |

≤13% |

Stainlesssteel |

40-50m2 |

|

GD-HG-2000 |

2tons/hour |

60kw |

380V/50Hz |

≤13% |

Stainlesssteel |

70-80m2 |

在线联系供应商

Other supplier products

| Cassava Centrifugal Sieve | Features of Cassava Centrifugal Sieve The slurry is pumped directly to the center of the conical rotating screen basket. Under centrifugal force, ... | |

| Hydraulic Dewatering Press | Hydraulic Dewatering Press sava processing machine Features of Hydraulic Dewatering Press Processing Capacity: 100-500kgs/hourApplication Scope: C... | |

| Centrifugal Dewatering Machine | Features of Centrifugal Dewatering Machine Processing Capacity: 1-10Tons/hour Application Scope: Cassava or potato starch dewatering Product Int... | |

| Hydraulic Dewatering Press | Features of Hydraulic dewatering press for sale Processing Capacity: 100-500kgs/hour Application Scope: Cassava slurry dewatering Product Introd... | |

| Cassava Stone Cleaning Machine | Features of Cassava Stone Cleaning Machine Used to remove the stones in the material such as rigid particles of impurities, at the same time have a... |

Same products

| 4-Shaft Winder Cast Film Machine | 卖方: Wenzhou Chaoshun Machinery Co., Ltd. | The 1500–2100mm PVC Cast Film Machine (4-Shaft Winder) is a robust solution built for indus... | |

| Standard Washer 12/15/20/25kg | 卖方: Jiangsu Chuandao Intelligent Equipment Co., Ltd. | Kingstar Series washer extractors equipped with the world’s leading washing technology, Ita... | |

| Daily Necessities Molds | 卖方: Zhuozhou Yihua Mould Factory | Daily Plastic Products are the most extensive category of plastic products. Most of the plastic p... | |

| Rebar Coupler Threading Machine | 卖方: Xingtai Yushi Machinery Equipment Co., Ltd | Rebar Coupler Threading Machineis an essential tool for processing reinforced bars, commonly used... | |

| VH HIGH-SPEED GANTRY PROCESSING | 卖方: Ling Yueyang International Trade (Shenzhen) Co., Ltd | ●Powerful cutting capability combined with high precision and performance makes insert and armori... |