Cassava Chips Machine 2019

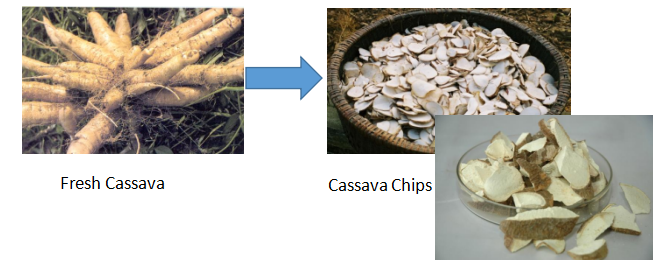

Cassava Chips Processing Description and Flowchart:

Cassava chips are one kind of chips or slices made from fresh cassava roots, as snacks or animal feed popular in many countries of West Africa and the Caribbean.

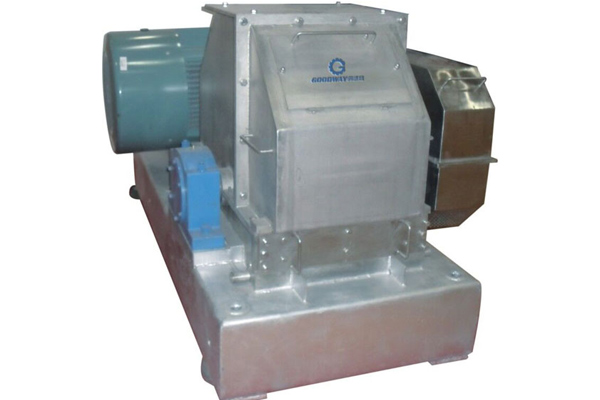

Goodway has 27 years of combined experience in the tapioca chips making machine and cassava chips processing machine.

Multiple distinct operations are required in cassava chips processing: washing, peeling, slicing, chips drying and packaging.

We provide below a brief description of the main steps of the cassava chips production process.

Cleaning and Washing Cassava Roots

Wash the fresh cassava roots in clean water to remove the surface mud and sand. It's the first step of cassava chips process and very important for the quality of final cassava chips.

Peeling Cassava Roots

Peel the washed cassava roots to remove the outer brown skin and inner thick cream layer. The water source should be checked regularly to ensure it is not dirty or contaminated.

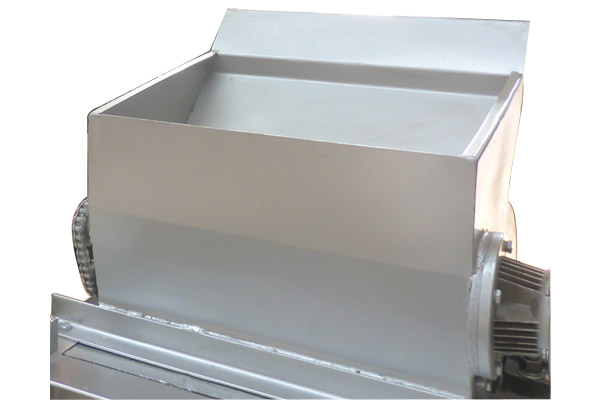

Cutting Cassava Roots into Wet Cassava Chips

Cut the peeled cassava roots into chips by the high speed rotating circular cutter blade, then cut the chips into strips by the cross cutter blade.

Drying Wet Cassava Chips into Dried Cassava Chips

Dry the wet cassava chips into dried cassava chips with low moisture content by the principle of heat transfer exchange.

在线联系供应商

Other supplier products

| Cassava Grinding Machine | Goodway is the manufacturer and supplier of cassava processing machine, focus on providing the whole range of equipment for the cassava processing ... | |

| Cassava Drying Machine | Features of Cassava Drying Machine Processing Capacity: 100-2000Kgs/hourApplication Scope: Cassava starch and flour dryingProduct Introduction: Air... | |

| Cassava Rasper Machine | Features of Cassava Rasper Machine Cassava Crusher - Cassava Rasper Machine Processing Capacity: 15-35Tons/hour Application Scope: Crushing the ... | |

| Cassava Chips Machine | Cassava Chips Processing Description and Flowchart: Cassava chips are one kind of chips or slices made from fresh cassava roots, as snacks or anim... | |

| Cassava & Potato Processing Line | As a professional and reliable manufacturer and supplier, Goodway focus on designing and providing turnkey solutions of cassava & potato proces... |

Same products

| 4-Shaft Winder Cast Film Machine | 卖方: Wenzhou Chaoshun Machinery Co., Ltd. | The 1500–2100mm PVC Cast Film Machine (4-Shaft Winder) is a robust solution built for indus... | |

| Standard Washer 12/15/20/25kg | 卖方: Jiangsu Chuandao Intelligent Equipment Co., Ltd. | Kingstar Series washer extractors equipped with the world’s leading washing technology, Ita... | |

| Daily Necessities Molds | 卖方: Zhuozhou Yihua Mould Factory | Daily Plastic Products are the most extensive category of plastic products. Most of the plastic p... | |

| Rebar Coupler Threading Machine | 卖方: Xingtai Yushi Machinery Equipment Co., Ltd | Rebar Coupler Threading Machineis an essential tool for processing reinforced bars, commonly used... | |

| VH HIGH-SPEED GANTRY PROCESSING | 卖方: Ling Yueyang International Trade (Shenzhen) Co., Ltd | ●Powerful cutting capability combined with high precision and performance makes insert and armori... |