Electroplating

ElectroplatingServices

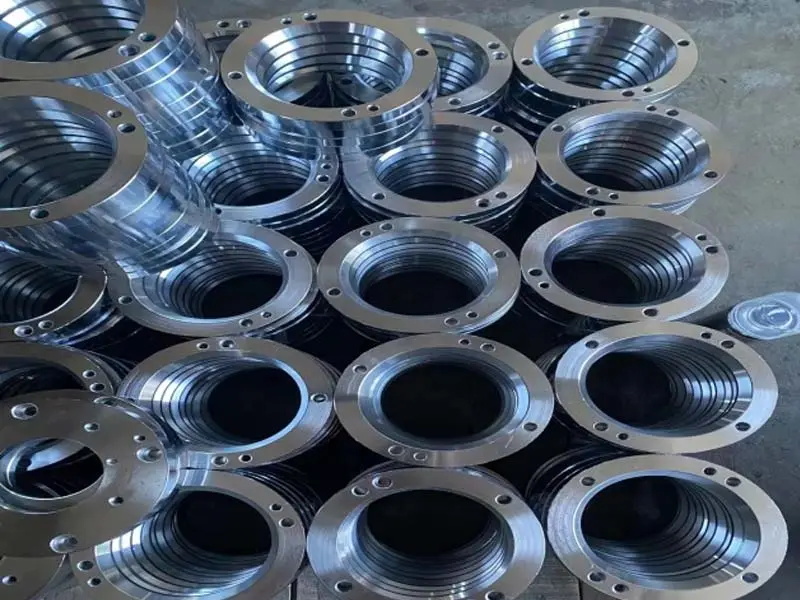

The custom electroplatingprocess is a method of laying a layer of metal on a conductive body using the principle of electrolysis. Plating electroplatingis a surface processing method in which the cations of the pre-plated metal are deposited on the surface of the base metal by electrolysis in a salt solution containing pre-plated metal, with the plated base metal as the cathode, to form a coating.

Electroplating Process Requirements

There should be good bonding between the plating and the base metal, and between the plating and the plating.

The plating should be crystalline, flat and of uniform thickness.

The plating layer should have the specified thickness and as few pores as possible.

The plating should have the required indicators, such as brightness, hardness, conductivity, etc.

The plating time and the temperature of the plating process determine the size of the thickness of the plating.

The ambient temperature is -10℃~60℃;

The input voltage is 220V±22V or 380V±38V;

The maximum working noise of the water treatment equipment should be no more than 80dB(A).

Relative humidity (RH) should be no more than 95%;

Raw water COD content is 100mg/L~150000mg/L.

Electroplating Process

It generally includes three stages: pre-treatment before plating, plating and post-plating treatment.

Complete process: 1, acid immersion → full plate plating

copper → graphic transfer → acid degreasing → secondary counter-current rinsing → micro-etching → secondary → immersion acid → tin plating → secondary counter-current rinsing 2, counter-current rinsing → immersion acid → graphic plating copper → secondary counter-current rinsing → nickel plating → secondary washing → immersion citric acid → gold plating → recycling → 2-3 level pure water washing → drying

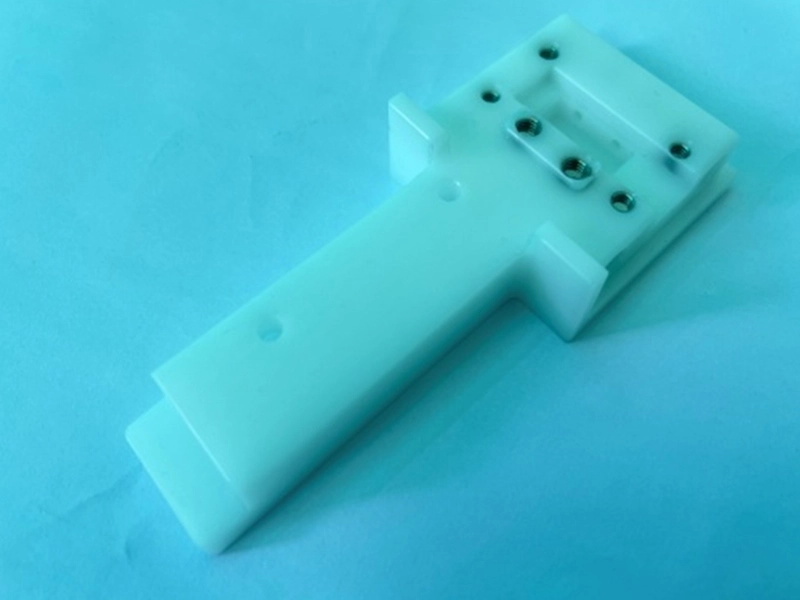

Plastic shell plating process

Chemical degreasing - water washing - dip acetone - water washing - chemical roughing water washing sensitization - water washing - activation - reduction - chemical copper plating - water washing bright sulfate copper plating - water washing - bright sulfate nickel plating - water washing - bright chromium plating - water washing drying for inspection.

As one of electroplating suppliers, electroplating companies, electroplating manufacturers, we will do our best to meet all the needs of customers.

We are one of the leading china precision machiningcompanies in China, committed to manufacturing the best prototypes and precision parts for a wide range of industries, including Artificial Intelligence, Automation Industry, New energy industry, Transportation industry, Internet Communication, Smart Home, Environmental Protection, Fixture & Tooling.

If you are looking for a reliable precision machining manufacturer, please choose us, and we will be your best partner.

在线联系供应商

Other supplier products

| Nylon Non-standard Parts | Nylon Non-standard Parts Nylon is a tough angular translucent or milky white crystalline resin, as engineering plastics nylon molecular weight is g... | |

| Plastic CNC Machining Parts | Commonly used materials for plastic parts processing: ABS, POM, PC, PEEK, Bakelite, Nylon, etc. Specifically can be used for 3D printing, rapid pro... | |

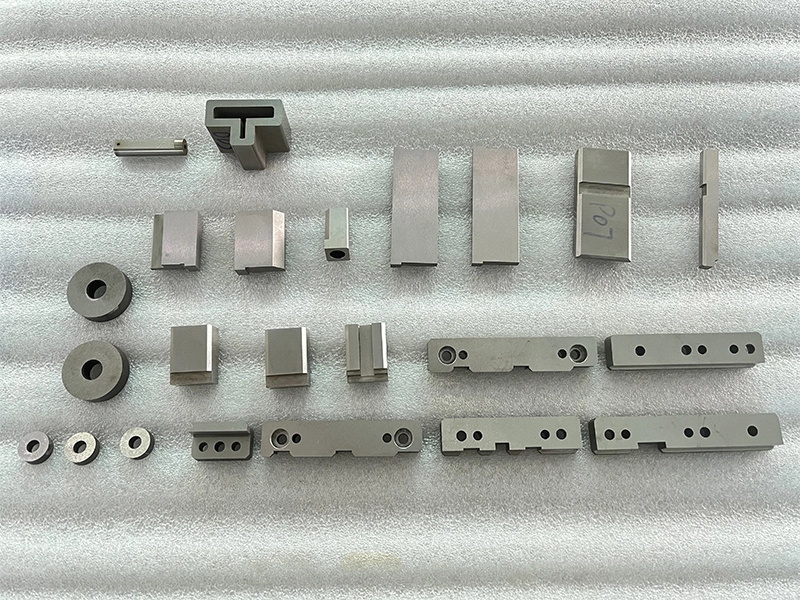

| Non-standard Parts | Standard parts are parts produced in accordance with national standards (GB), industry standards, or foreign standards, mainly for the convenience ... | |

| Copper Precision Spare Parts | Copper Precision Spare Parts T1, T2 copper is mainly used as conductive, heat-conducting and corrosion-resistant components, such as wires, cables,... | |

| PEEK Non-standard Parts | PEEK Non-standard Parts PEEK material is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mec... |

Same products

| Tool Scoot – Heavy-Duty CNC Tool Holder Storage by Uratech | 卖方: Uratech USA Inc | Tool Scoot– Heavy-Duty CNC Tool Holder Storage by Uratech When precision, mobility, and du... | |

| Car Signs Molds | 卖方: Zhuozhou Yihua Mould Factory | Our company has long provided automobile manufacturers with automobile sign moldsand products. Au... | |

| DG-I Gantry Crane Rail Changer | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| 便携式轨道垂直捣固机 | 卖方: 武汉联科瑞际轨道设备有限公司 | ||

| NSiC stalk tube,NBSiC stalk ceramic, advanced NSiC riser tube, nitride bonded silicon riser tube, LPDC machine parts | 卖方: 唐山星斗碳化硅陶瓷有限公司 | 星斗公司的升液管作为低压铸造机上的关键部件,具有较好的耐热冲击性、耐腐蚀性、较传统材料寿命更长,性价比更高,可以很好的满足低压铸造行业要求。 |