Dynamic Image Analysis

Dynamic ImageParticle Analysis

Most particle size measurement techniquesare based on the assumption of spherical shaped particles. This hypothesis leads to significant errors in the analysis if the particles are flake or rod-shaped. Especially for such highly form-anisotropic particles, automated imaging provides an excellent alternative for the determination of tailor-made size specifications.

Automated imaging methods for the determination of the particle size distribution of a material offers a fundamental advantage over alternative methods such as static light scattering, sedimentation or sieving: Each particle is photographed individually! This results in several important advantages for the determination of the particle size distribution:

Realistic proportional values also at the edges of the size distribution, i. e. detection of oversized particles or fine particles

Visual assessment of the dispersing state of a sample (dispersing quality, presence of agglomerates)

Calculation of meaningful size parameters, e. g. geodetic length or Feret diameter for fibres, depending on the application

Selection of the appropriate distribution type (volume, number) depending on the particular task

In addition, the individual photography of the particles gives the opportunity to make statistical calculations on the particle shape, which in practice enables further differentiation of materials. For example, form anisotropy, the deviation of the particles from the ideal sphere, often plays a decisive role for their application and further processing – for example, the conveyance or compaction of powders, the influence on the rheology in dispersions or, in addition to the particle size distribution, the roughness of the particle surface plays an important role for the success of shaping or polishing.

The necessity for tailor-made particle size and shape parameters, combined with ever-increasing PC processing power, ensures that automated imaging methods are becoming increasingly more relevant to a market which is 95% non-spherical..

BeVision D2

Particle size and particle shape:

Dry: 30µm to 10000µm

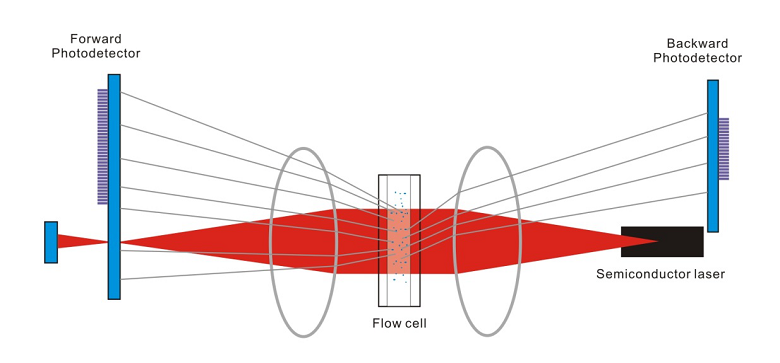

Bettersizer S3 Plus

2 to 3500μm(Image System)

BeVision M1

Particle size and particle shape:

1 to 10,000µm

If you want to know more types of particle size instrument, please contact us.

At Bettersize, our mission is to provide best-in-class laser particle sizingand characterization instruments, comprehensive solutions and exceptional customer services. We are dedicated to assist scientists, researchers and engineers around the world to understand material properties, facilitate research, improve production efficiency and beyond.

在线联系供应商

Other supplier products

| Dynamic Image Analysis | Most particle size measurement techniquesare based on the assumption of spherical shaped particles. This hypothesis leads to significant errors in ... | |

| Bettersizer ST | Laser Particle Size Analyzer, Laser Granulometry Bettersizer ST laser scattering particle size distribution analyzerincludes the patented Dual Lens... | |

| Powder Characterization | Powder characterizationincludes flow measurements, morphology, particle size distribution, density and chemical composition. Bettersize PowderPro S... | |

| HFlow 1 | Metal Powder Flowability Tester HFlow-1 tests the flowability of metal powder by measuring whether the sample can flow through the 2.5mm standard f... | |

| Laser Diffraction | Particle size measurement using static light scattering (Particle size determination by laser diffraction) The particle size distribution as a para... |

Same products

| UV Detector | 卖方: 淮安市鑫盛制药设备有限公司 | The ultraviolet-visible dual-wavelength detector features high sensitivity and a wide linear rang... | |

| Fabric ici pilling and snagging box | 卖方: 标准集团 | Fabric ici pilling and snagging boxis composed of the same speed motor drive, and to maintain the... | |

| Martindale Abrasion And Pilling Tester | 卖方: 标准集团 | To determine the abrasion and pilling resistance of all kinds of textile structures. Samples are ... | |

| Circular Locus Pilling Tester | 卖方: 标准集团 | Testing Standards: GB/T 4802.1. JIG 040-1990 Product Information: The Circular Locus Pilling... | |

| Bean Bag Snag Tester | 卖方: 标准集团 | Bean Bag Snag Tester, to determine the snagging and picking resistance of knitted and woven fabri... |