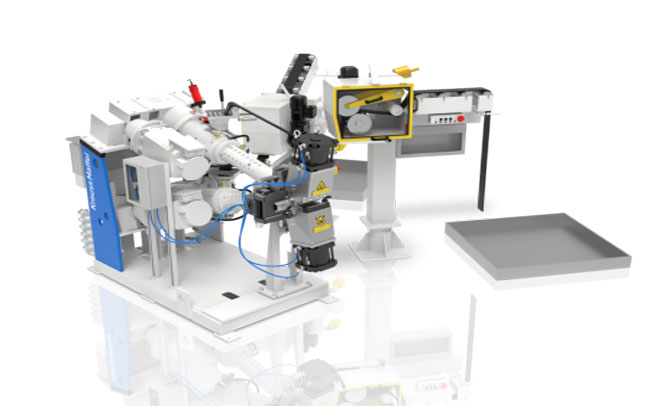

PLASTIC AUXILIARY MACHINERY

Plastic Auxiliary Machinery By Soxi: Always The Right Choice

Are you in the market for a new injection molding machine but just not sure how or where to start?

It is more complicated than ever before with what seems to be an endless variety of types and brands of plastic auxiliary machine to choose from; hydraulic, electric, hybrid, high or low clamp tonnage, general purpose screws, or something tailored to the type of plastic part and material for your project.

What Is Plastic Auxiliary Machinery?

If you’re reading this, chances are you already know a thing or two about plastic injection molding. There are many reasons why the process of injection molding is very popular in the field of plastic production—the most common reason is that it is the best means of producing enormous and identical quantities of plastic machinery parts. There are many different types of molding machines in plastic machine factory, depending on what you are creating and how the plastic auxiliary machine affects the product. Plastic auxiliary equipment are classified mainly by the type of driving system they use: hydraulic, electric, and hybrid.

What Is The Difference Between Thermoforming And Injection Molding?

The differences and similarities between thermoforming and injection molding are a question we get a lot. Someone comes to us with a project, trying to understand the two processes. Both are popular manufacturing processes for producing plastic parts. While thermoforming is generally used for large designs and smaller production runs, injection molding tends to be used for small intricate parts and large production runs. Here are some brief descriptions of the two processes.

Tooling

In the tooling phase of thermoforming a single 3D form is created out of aluminum, wood, polyurethane, or a 3D printer. In injection molding, a double-sided 3D mold is made from aluminum, steel, or beryllium-copper alloy. There is an advantage in timing and plastic machinery price with thermoforming since prototype samples can be made from CNC cut wood tooling. Tooling costs for large product tooling are substantially less with thermoforming.

Materials

Thermoforming can use a variety of different materials to create flat sheets that get molded into the product. There are options for a different finish, color, and thickness of the product. Injection-molded products use thermoplastic pellets, that are available in a wide variety of materials and colors as well.

Production

In thermoforming, a flat sheet of plastic is heated to a pliable temperature, then molded to the tool's shape using suction from a vacuum or both suction and pressure. In injection molding, plastic pellets are heated to a liquid state and injected into the mold.

What Is Moulding And Types Of Moulding?

Plastic molding is a type of plastic forming, Plastic molding is a process in which plastic materials are formed by means of a mold or mouth model under pressure (usually heated).It is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object. There are several types of molding which include compression, injection, liquid, blow, and transfer molding. SOXI provides three types of molding auxiliary equipment for plastics processing, IMM injection molding machine, and reaction process machinery, and plastic extrusion machine.

Other supplier products

|

|

MASTERBATCH MIXER |

The horizontal masterbatch mixeris a horizontal paddle, the blade is made of thick stainless steel, and the distance from the barrel wall is accura... |

|

|

SOXI PLASTIC MOLDING MACHINE MANUFACTURERS |

Are you in the market for a new plastic moulding machine but just not sure how or where to start? Soxi can be your competitive plastic molding mach... |

|

|

PLASTIC MATERIAL MIXER MACHINE |

Soxi is one of the safe and reliable plastic mixer machine manufacturers. Pastic mixer machine is used for the precision proportioning of multi-typ... |

|

|

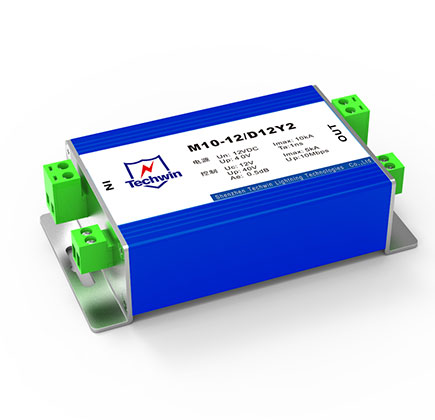

MOLD TEMPERATURE MACHINE CONTROLLER BY SOXI: ALWAYS THE RIGHT CHOICE |

Mold temperature machine, MTC, mold heater, In a broad sense, called mold temperature controller, oil/water mold heaters. Mold temp controller cont... |

|

|

EXTRUSION TECHNOLOGY (EXT) |

Soxi is synonymous with reliable and sustainable extrusion technology solutions worldwide. Areas of application include venting and compounding in ... |

供应产品

Same products