Plastic Injection Molding

Plastic Injection Molding

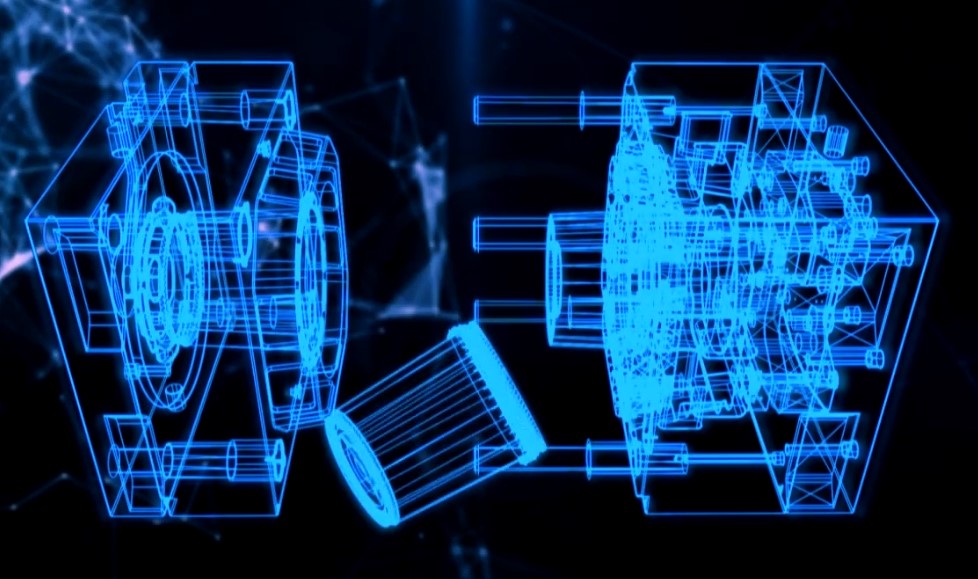

What is plastic small scale injection molding? Plastic Injection molding is a molding method that combines injection and molding. The advantages of plastic injection molding method are fast production speed, high efficiency, operation can be automated, variety of colors, shapes can be from simple to complex, size can be from large to small, and sizes of injection moulding supplies are accurate. The plastic injection moulding product is easy to update, and it can be made into complex shapes. Parts, injection molding/injection moulding is suitable for mass production and plastic molding processing fields such as products with complex shapes.

Plastic Injection Molding Basics

Keyplast plastic injection molding is a molding process that two metal mold halves (called core and cavity) come together and manufacture a formed part by injecting plastic materials into the cavity at a predetermined temperature and pressure, until left to cool and solidified to the shape of the mould.

As a professional injection moulding business in the plastic injection molding field, Keyplast plastic injection molding manufacturer not only provides different types of injection mold toolings such as double shot molding, insert injection molding, overmolding injection molding and materials used in injection moulding with competitive injection molding prices, but offers custom injection molding as well.

Plastic Injection Molding Process

Plastic injection molding is the process of melting plastic particles (thermosetting/thermoplastic polymers) and, once malleable enough, injecting them under pressure into a mold cavity, filling and curing to produce the final plastic injection moulding products.

How Does Plastic Injection Molding Work ?

The molding machine heats the plastic to a liquid state. The nozzle of the plastic injection machine then injects the melted plastic into the mold (injection pressure). The cavity of the mold is filled with plastic fluid and then cool to form a solid plastic molded product.

Plastic Injection Molding Technology

01

Cylinder temperature

The temperature that needs to be controlled during the injection plastic moulding process includes the temperature of the barrel, the temperature of the nozzle and the temperature of the mold, etc.

02

Nozzle temperature

The nozzle temperature is usually slightly lower than the maximum temperature of the barrel during the injection molding processs of plastic mold tooling, this is to prevent the "salivation phenomenon" that may occur in the straight-through nozzle of the molten material.

03

Mold temperature

The mold temperature has a great influence on the internal performance and apparent quality of the plastic mould tooling. The temperature of the mold depends on the crystallinity of the plastic, the size and structure of the product, and the performance requirements.

04

Injection pressure

In the current production of plastic injection moulding for sale, almost all the injection pressure of the injection machine is based on the plunger or the top of the screw to the plastic.

05

Plasticizing pressure (back pressure)

When using a screw injection machine to produce plastic moulds for sale, the pressure on the top of the screw when the screw rotates and retreats is called plasticizing pressure, also known as back pressure. The size of this pressure can be adjusted by the overflow valve in the hydraulic system.

Advantages Of Plastic Custom Injection Moulding

Now the price of china plastic injection machineis reasonable, if you have needs, please contact us.

在线联系供应商

Other supplier products

| Gardening Injection Molding | Keyplast brings every concept into a reality, not only for every client, but also for our own development in all areas, especially in gardening ind... | |

| Market Status Of China's Mold Manufacturing Industry | In recent years, due to the continuous improvement of China's industrialization, China has become a major mold manufacturing country and a major mo... | |

| Two Shot Molding | Two shot molding, also called double shot moulding, dual shot injection molding,multi shot injection molding or 2k injection moulding is one catego... | |

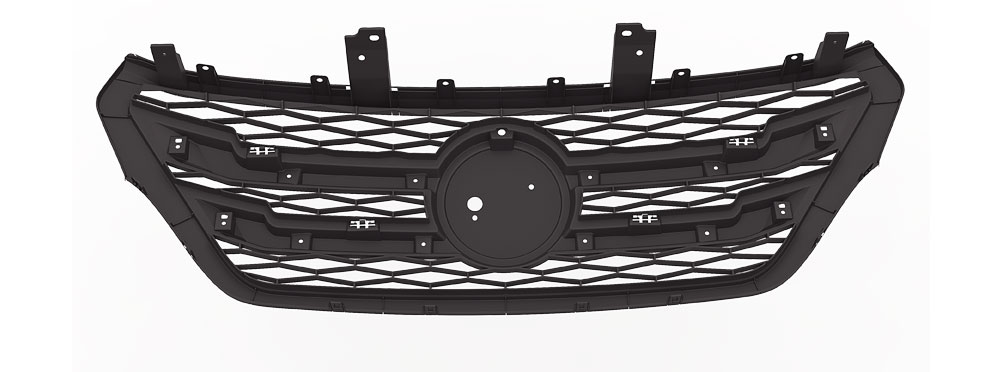

| Automotive Injection Molding | As a professional automotive plastic injection molding companiesKeyplast offers one-stop solutions for automotive industry. Many customers from aut... | |

| What is the Difference Between Overmolding and Insert Molding? | What Is the Difference between Insert Molding and Overmolding Plastic injection molding is one of the most widely used processes for manufacturi... |

Same products

| Two-Shot Injection Molds | 卖方: WIT MOLD LIMITED | Two-Shot Injection Molds Advantages of two-shot injection molding The benefits of Double Inject... | |

| precision injection molding | 卖方: WIT MOLD LIMITED | precision injection molding Precision injection moldingis a method demanding unparalleled accura... | |

| Custom Plastic Molds molding | 卖方: WIT MOLD LIMITED | Custom Plastic Molds molding Plastic Molds molding servicesprovide many extremely versatile part... | |

| Negative Pressure Physiotherapy Tank Molds | 卖方: Zhuozhou Yihua Mould Factory | The negative pressure tank is a disposable consumable for male negative pressure treatment. This ... | |

| PLC Casing Molds | 卖方: Zhuozhou Yihua Mould Factory | The PLC housingbelongs to a kind of rail electrical module. It not only needs to achieve the fit ... |