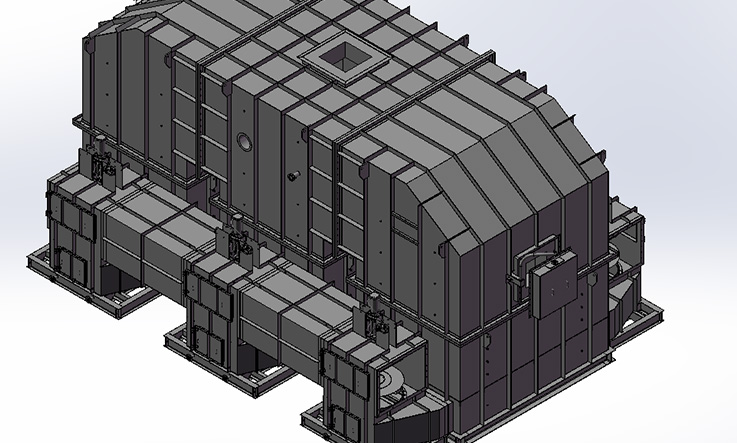

Metal Heat Transfer Thermal Oxidation Device(TNV)

Metal heat transfer thermal oxidation device(TNV) is used to purify industrial waste gases containing high concentrations of organic pollutants, The system is characterized by a very high utilization rate of heat in system. Combined with a downstream heat recovery system, the unit is inexpensive to operate and requires only a small amount of external fuel heating.

HOW DOES THE TNV TECHNOLOGY WORK

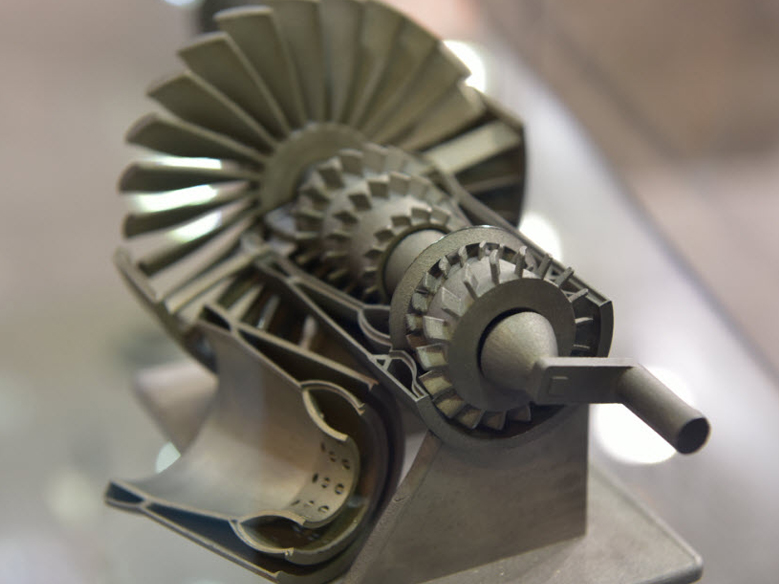

After a heat transfer, the exhaust gas is directly burned by the combustion machine, combined with the heat released by the oxidation and decomposition of the solvent itself, which makes the furnace reach 750~800℃, and stays for 1~2 seconds, and the final destruction efficiency can reach 99.8%.

TNV Air Flow Range & Efficiency

Applicable flow rates from 2,000 to 55,000 Nm³/h

Heat utilization of 76% within the system

Heat recovery systems for air, water, oil, steam, and for absorption chillers

Low maintenance

Long service life

Easy operation

TNV Design Features

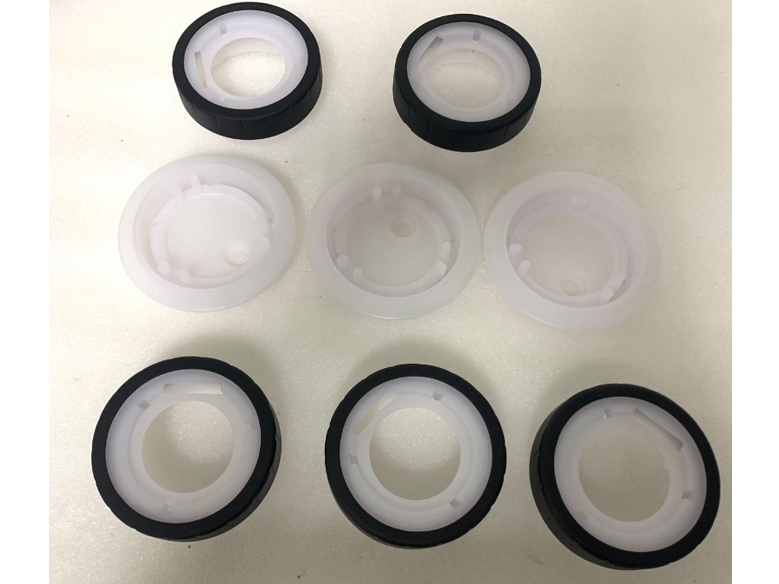

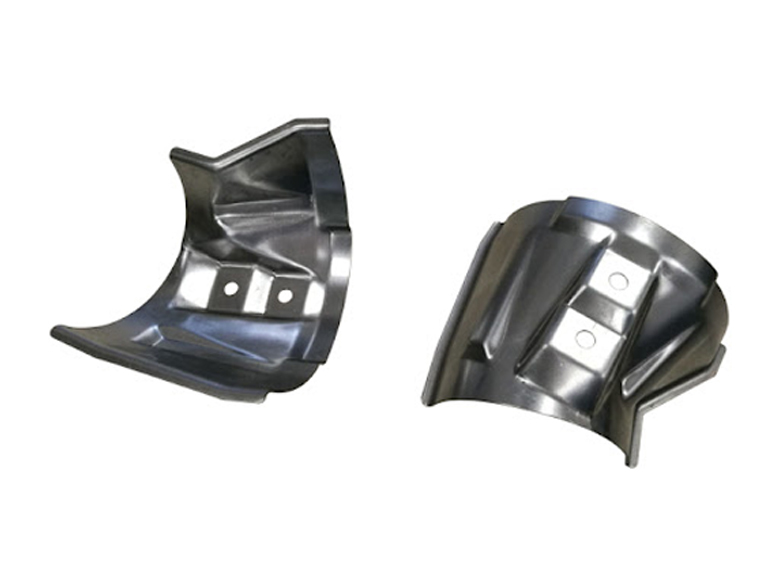

Preheating device: The metal direct fired thermal oxidizer(dfto) needs to be heated to above 700 degrees to start the oxidation reaction. The system requires a large amount of heat. The use of a preheating heat exchanger, along with the heat from the high-temperature exhaust gas exiting the oxidizer, can significantly reduce fuel consumption.

Automatic temperature control: The temperature for carrying out the oxidation reaction can be set as required, and the output of the burner is automatically adjusted by PLC to maintain the temperature according to the temperature inside the metal heat transfer thermal oxidation device (TNV).

As one of offset printing press manufacturers, we can offer sorts of offset printing press machinefor sale, if you have needs, please contact us.

在线联系供应商

Other supplier products

| Metal Coating Machine | Fully automatic metal coating is the essential process for anti-rust and brightness effect before and after printing for metal sheets made of tinpl... | |

| Metal Printing & Coating Machines And System Automation Solution | RUIYUAN has been a designer and manufacturer of metal printing and coating equipment for over 20 years. we committed to Manufacture Top World Class... | |

| Automatic Pile Turner Machine | Automatic Pile Turner Machine Our pile turner machineare mainly for metal printing and coating. The working platform is plate type or drum type, e... | |

| Regenerative Thermal Oxidizer (RTO) | Regenerative Thermal Oxidizer (RTO) produced by RUIYUAN uses ceramic media to recover upwards of 97% of the available energy and is widely consider... | |

| Metal Heat Transfer Thermal Oxidation Device(TNV) | Metal heat transfer thermal oxidation device(TNV) is used to purify industrial waste gases containing high concentrations of organic pollutants, Th... |

Same products

| Vacuum Casting Plastic | 卖方: Industry Proto-mold Limited | Vacuum casting process: free mold opening, low production cost, forming speed, high processing ac... | |

| Titanium 3D Printing Service | 卖方: Industry Proto-mold Limited | Titanium 3d printing servicefor Titanium alloy parts has very high strength, precise dimensions, ... | |

| Stamped Sheet Metal Parts | 卖方: Industry Proto-mold Limited | Stamped Sheet MetalParts Proto-mold purchased advanced large laser cutting machine 3 sets, Amada... | |

| Stainless Steel Printing | 卖方: Industry Proto-mold Limited | For parts with complex structure, stainless steel 3d printing servicecan realize integral printin... | |

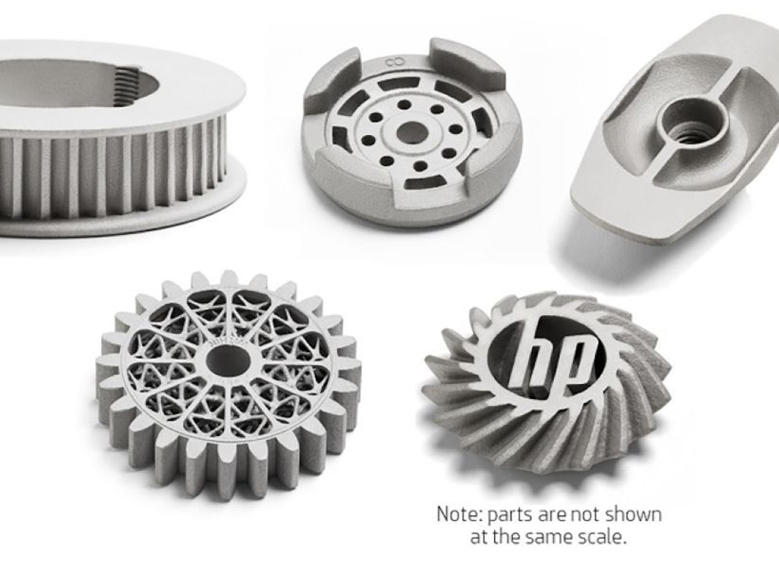

| SLS Nylon Printing | 卖方: Industry Proto-mold Limited | 3D printed nylon parts can be used for product verification or directly used as functional produc... |