China Sheet Metal Fabrication

Custom sheet metal fabrication services is a comprehensive cold working process for precision custom sheet metal fabrication company to produce sheet metal (usually less than 6mm thickness), including shearing, punching/cutting/compounding, folding, welding, riveting, splicing, forming.

Types of China Sheet Metal Fabrication Service

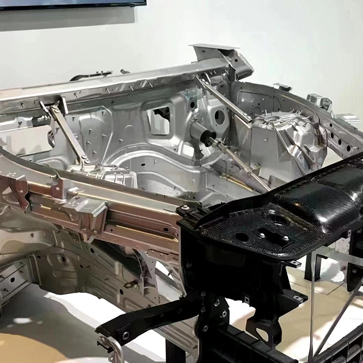

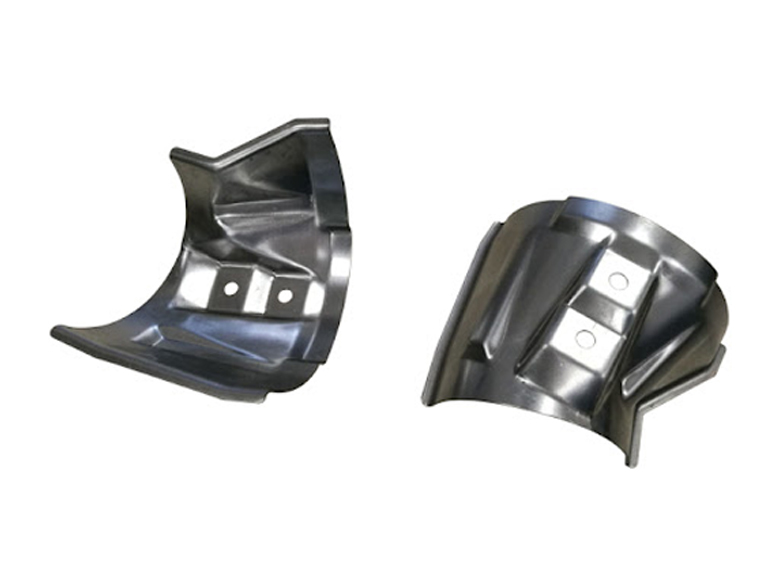

Automobile Sheet Metal Parts

Our automotive sheet metalwork service provides high-quality, state-of-the-art parts to a wide variety of automotive customers. With the ability to produce parts of virtually any size and to the highest standards, it is no wonder that automotive sheet metal fabrication industry leaders have relied on Advanced Metal Forming Stamping and Automotive Part Forming for over 20 years.

Stamped Sheet Metal Parts

Sheet metal parts have the characteristics of lightweight, high strength, electric conductivity, low sheet metal fabrication cost, good mass production performance, etc., and sheet metal forming stamping has been widely used in electronic appliances, communications, automobile industry, medical equipment, and other fields.

Precise Sheet Metal Fabrication China Benefits

Most sheet metal parts consist of multiple bends and cuts. Precise sheet metal fabrication service utilizes a variety of different techniques, including custom sheet metal bending, custom metal plate cutting, and sheet metal fabrication welding. Automated sheet metal fabrication service is used in a wide variety of industries. In automotive sheet metal components manufacturing, sheet metal parts are used to create car frames, bumpers and grills; in the construction industry they are used to build fences; in landscaping they can be utilized to create decorative gates or arbors.

With precise control over each aspect of the prototype service manufacturing process, sheet metal fabrication company can be able to deliver superior results. Precision and accuracy are key to successful fabrication metal sheet . Without them, your project will be a disaster. A good design is needed in order to achieve the desired effect.

Precise sheet metal fabrication service is a versatile and customizable method of creating products. The low cost sheet of metal fabrication material makes it ideal for use in mass production, and its durability makes it perfect for long-lasting solutions.

The wide range of applications for sheet metal fabrication is one of the most important benefits. Sheet metal parts can be used to create anything from simple household goods such as light fixtures and bird feeders to complex machinery like airplanes and rockets. Additionally, sheet metal parts can be formed into parts with shapes that are not possible using other methods such as molding or casting; this gives precision sheet metal fabrication manufacturers more freedom when designing their products!

Automated Sheet Metal Fabrication China Material

Precise and automated sheet metal fabrication service is a manufacturing process that has been used for many years to create parts from raw materials. The process involves precision sheet metal cutting, bending and joining flat pieces of metal. There are many different types of metal available in sheet metal forming process including aluminum, steel and other metals. There are titanium sheet metal fabrication, copper sheet metal fabrication and steel sheet metal fabrication.

They range from aluminum, mild steel and stainless steel to copper, brass and bronze alloys. Some metals are more common than others depending on the job at hand. For instance, steel is probably the most commonly used material for sheet metal fabrication because it can be cut easily with a saw or plasma cutter and welded together easily by various methods. If you want to fabricate something out of titanium you will need to look into special machines designed for this purpose because it is much harder than other metals to cut or weld with regular tools like torches and welding equipment.

Some metals are stronger than others as well as being more expensive so they may not always be worth using if there is another option available such as galvanized steel which combines iron with zinc making it cheaper but still strong enough for most jobs requiring strength like fencing panels or vehicle parts such as bumpers mounts etc... Other materials include zinc which usually comes in sheets pre-coated with lacquer or enamel paint so they do not rust easily .

China Sheet Metal Fabrication Process

Sheet metal fabrication service is the intricate process where various pieces of sheet metal are bent, cut and welded together to create a product. The most common type of sheet metal fabrication includes the steps of cutting, forming and welding.

Sheet cutting service

After you've determined what piece of sheet metal you need, it is time to cut it. Sheet cutting service is done with a saw or punch.

Laser metal forming

The forming process is a critical part of the sheet metal fabrication process. It consists of bending sheet metal into a desired shape using a variety of tools, including hammers, dies and presses.

One common example is when you're going to cut out a piece of sheet metal with a saw blade. You have to clamp your material down so it doesn't move around while you're cutting through it. If you don't clamp it down properly then there's going to be too much movement in your material and this can result in an inaccurate cut or even worse: having to start over from scratch.

Welding sheet metal fabrication

Welding sheet metal fabrication is the process of joining metal by melting it. When you weld one piece to another, they become one solid piece. Welding is often used in construction projects or manufacturing.

In welding, you use a welder and electricity to heat up the bare metal until it melts and flows together. You can weld many different types of metals, including steel and aluminum. This type of welding is called “stick welding” because you have to keep a stick of heated material moving over the pieces being joined as they're being melted together by an arc between them generated by an electric current passing through the wire from your welder through an electrode holder connected to your workpiece

Finishing

Finishing is the final step of the fabrication process, and it's an important one. Because the product has been built up from raw materials, you want to make sure that it looks good. Finishing can include painting and powder coating. It could also include plating or polishing. Finally, adding decorative elements like logos or labels are also considered finishing touches.

As a product prototype maker, we will do our best to meet all the needs of customers.

Other supplier products

|

|

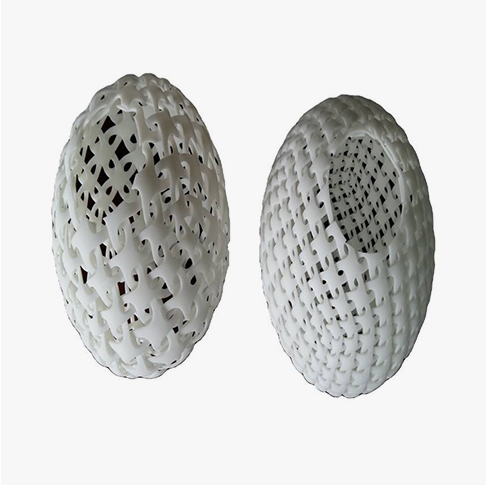

SLA Plastic 3D Printing |

SLA printingis focused on the surface of a light cured material, which is solidified from point to line and line to surface. SLA printing of SLA 3d... |

|

|

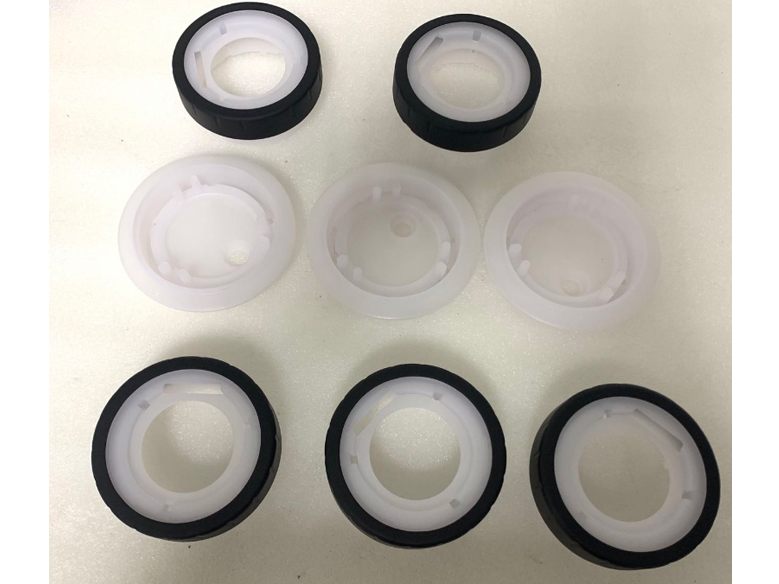

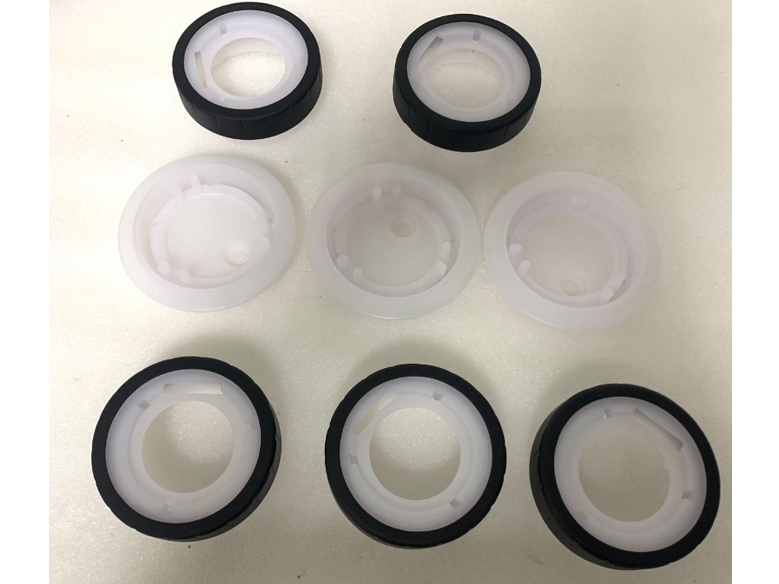

Silicone Prototyping |

Soft Rubber rapid prototype, Hardness is generally between shore A 30~90 degrees, because soft rubber plastic prototype has flexibility, it is wide... |

|

|

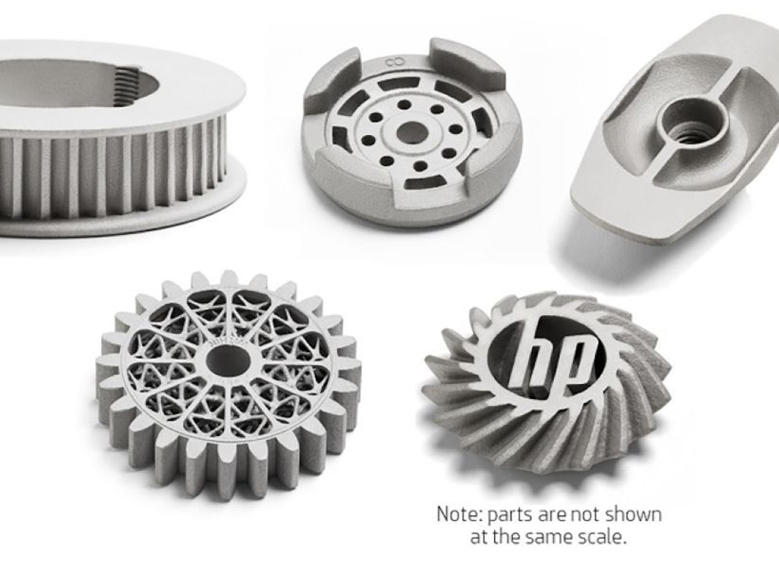

Stainless Steel Printing |

For parts with complex structure, stainless steel 3d printing servicecan realize integral printing forming, avoiding mass increase and potential qu... |

|

|

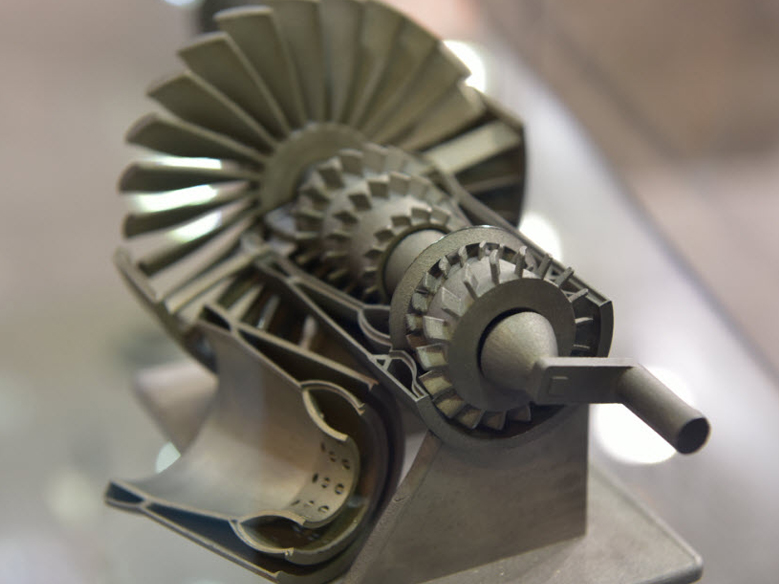

Titanium 3D Printing Service |

Titanium 3d printing servicefor Titanium alloy parts has very high strength, precise dimensions, and their mechanical properties are better than th... |

|

|

Vacuum Casting Plastic |

High vacuum die casting process: free mold opening, low production cost, forming speed, high processing accuracy, support small batch customization... |

供应产品

Same products