Silicone Prototyping

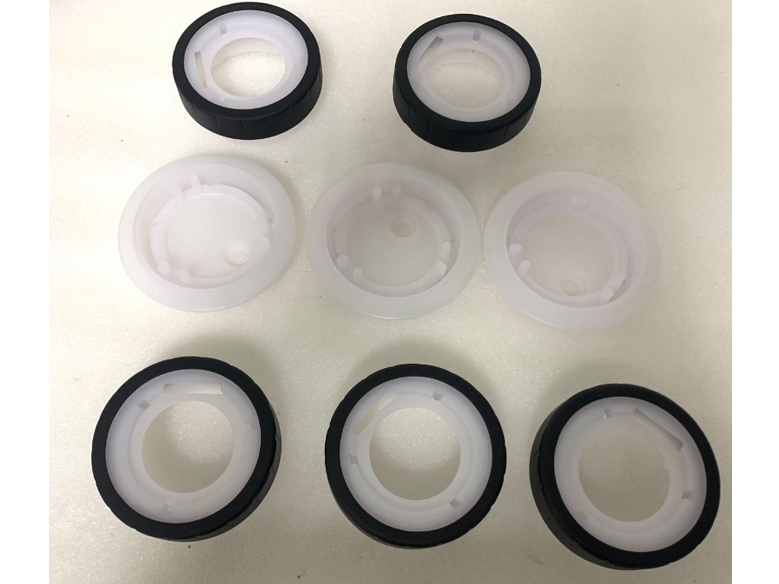

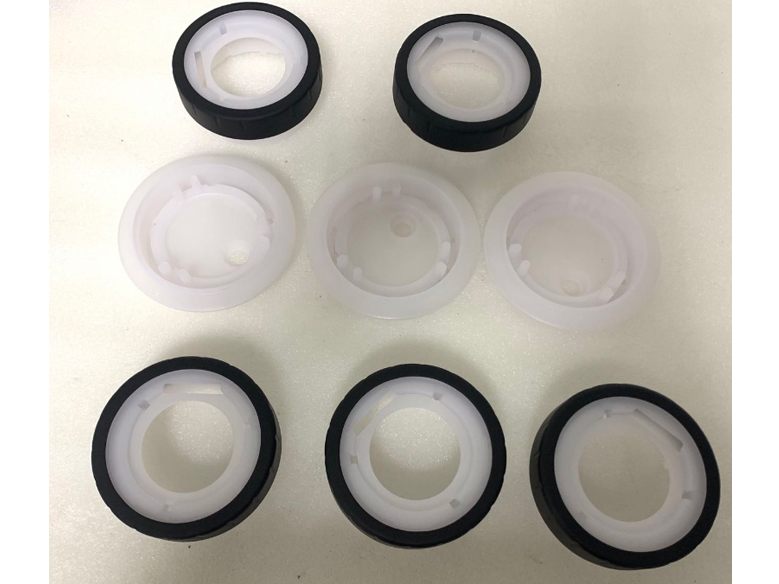

Soft Rubber rapid prototype, Hardness is generally between shore A 30~90 degrees, because soft rubber plastic prototype has flexibility, it is widely used in the rapid prototype industry. The processing method of soft plastic rapid prototype is relatively single, and it can only be processed by vacuum Casting - that is use 3D printing or CNC processing to do a prototype, and then use vacuum casting /silicone mold to copy the prototype, generally a prototype can be copied 15~20 time.

Silicone Prototyping Material Properties

In the general plastic industry, PP, PE and other light gravity, material surface hardness is relatively low plastic known as soft glue. And PS, ABS, AS, hard PVC and other plastics can be called hard glue.

Silicone Rapid Prototyping Material Info

Brief introduction

Soft rubber rapid prototype is mainly processed by the way of silicone compound mold, its advantages are fast time, less cost, good operation, no deformation, no shrinkage, easy to dismantle the mold, the mold surface is smooth, the simulation effect is good, the probability of processing failure is small. 10-20 pieces of the same product can be copied by using a silica gel mold. Generally, a set of silica gel mold can only be done about 10-20 times and can not be used. Reuse can produce deformation and large size error. Soft rubber hand model because of these excellent properties, so its application is very wide, Soft rubber hand model production steps can be divided into three steps, before making silica gel mold, first of all to make a prototype, the prototype can use the more common ABS material, can be made by CNC processing or 3D printing; After the original is ready, began to make silica gel mold, after curing, the silica gel mold is cut, take out the prototype, at this time the silica gel mold is ready; The liquid material is injected into the silica gel mold and dried. The service life of the silica gel mold is about 10-20 times. In the silicone cast prototypes industry, as long as the soft adhesive material is PU 8400.

If you want to know more kinds of rapid prototype silicone parts , please visit our website.

As one of prototyping companies, we will do our best to meet all the needs of customers.

Other supplier products

|

|

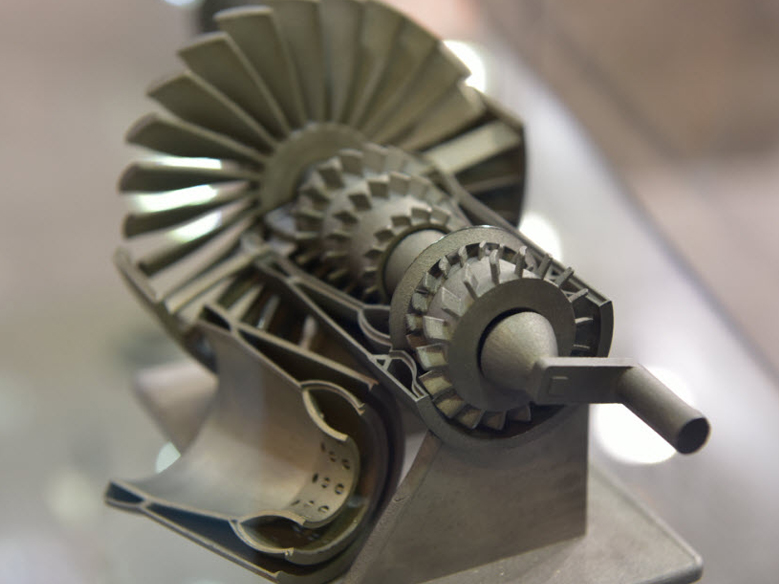

SLA Plastic 3D Printing |

SLA printingis focused on the surface of a light cured material, which is solidified from point to line and line to surface. SLA printing of SLA 3d... |

|

|

Vacuum Casting Plastic |

Vacuum casting process: free mold opening, low production cost, forming speed, high processing accuracy, support small batch customization and othe... |

|

|

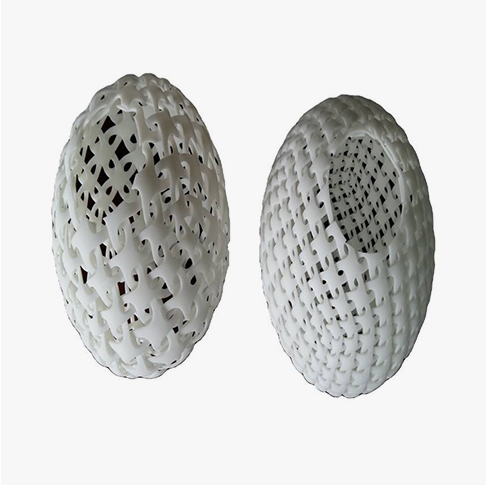

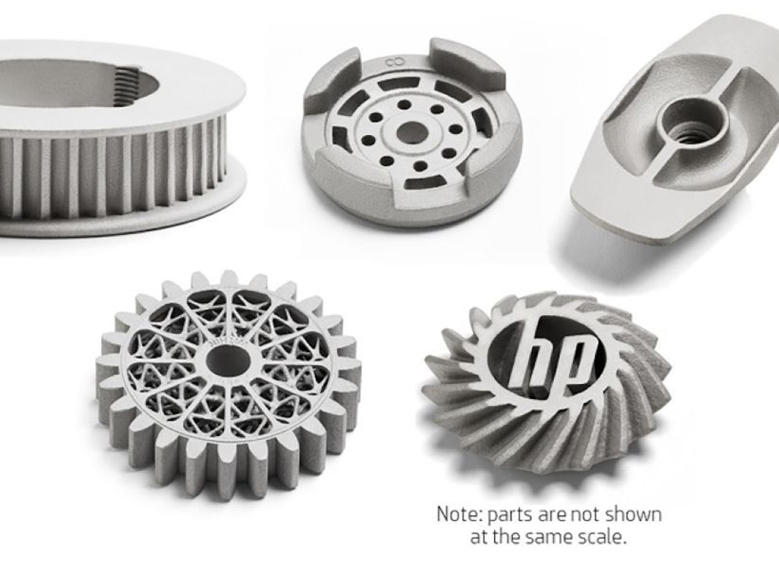

SLS Nylon Printing |

3D printed nylon parts can be used for product verification or directly used as functional products. The product is 3d prototype printing with ligh... |

|

|

Vacuum Casting Plastic |

High vacuum die casting process: free mold opening, low production cost, forming speed, high processing accuracy, support small batch customization... |

|

|

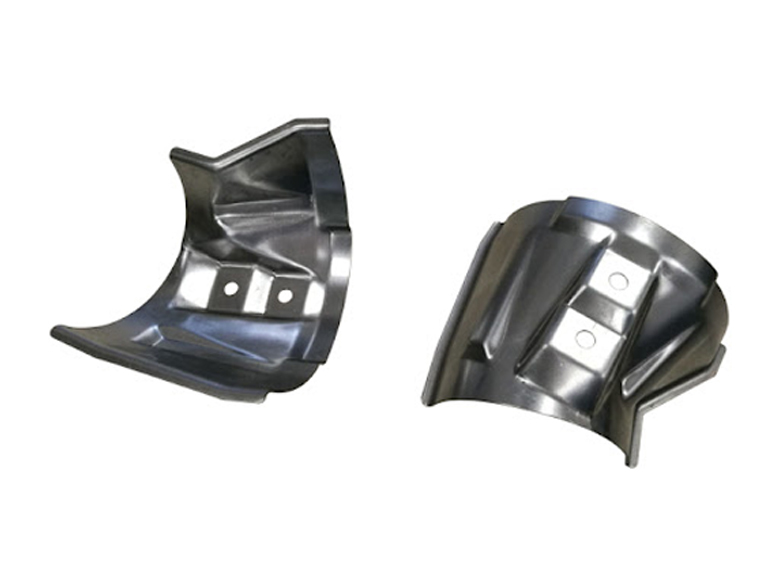

China Sheet Metal Fabrication |

China custom sheet metal fabrication servicesis a comprehensive cold working process for custom sheet metal fabricationcompany to produce sheet met... |

供应产品

Same products