Auxiliaries for Cotton and Its Blends

The cotton and its blends, also known as cotton, is a kind of woven fabric made of cotton yarn, which is one of the most commonly textile fabrics in clothing industry.

Cotton fabric manufacturing including spinning, weaving, knitting, dyeing, printing and finishing. The Spinning and weaving process is putting the textile fiber processed into yarn and fabric dyeing by machine, and finishing to reprocessing cotton fabric products by chemical and physical method of mechanical part. It can improve the performance of fibers and its products and improve its appearance by finishing processing. Therefore, textile agent and auxiliary chemicals is an indispensable part in textile industry. During finishing process, there is a pretreatment of textile fabric. You have to use good cotton chemistry and achieve good performances.

HT fine textile auxiliaries chemicalscan meet your requirements, chemicals used in cotton production such as wax removing agent, sequestering powder CT, water softener, peroxide stabilizer, scouring agent, bio-polishing enzyme, acid releasing agent for textile chemical, scouring enzyme, peroxide killer etc. All of these cotton chemistry products are safe and environmental protection. We are the manufacturer of auxiliaries for cotton and its blends, we can supply best chemical auxiliary agent.

Scouring Agent of Cotton Fabric

[Brief information]

--It is widely used in textile processing. It has good emulsification, dispersion, penetration ability, can remove all kinds of dirt fabric, grease substance, floating color.

[Main composition]

--Variety of mixed surfactant compound.

[General properties]

--Appearance: colorless transparent liquid

--Ionicity: nonionic

--pH: 6 – 7

--Stability: stable to acid, alkali, water and electrolyte.

--Solubility: easily soluble in water

[Properties and fields of application]

--It is mainly used for pretreatment process for removal of sizing agent and oil.

--It has excellent emulsification, dispersion, penetration and dissolution in oil for sizing agent and chemical slurry.

--Greatly improve the quality and efficiency of pretreatment, with low foam and easy cleaning, also save water.

[Application]

Under a variety of conditions, it has outstanding penetration. Suitable for the pretreatment and dyeing of cotton and blended fabric.

--Pretreatment: 1 - 3g/l

--Staining: 1-3g/l

[Packing and storage]

-- Packing: 125 kg/polyethylene drum

-- Storage: 6 months in sealed container at room temperature.

Low Temperature Scouring Agent in Textile HT-DJ133

[Main composition]

-- Surfactant compound.

[General properties]

-- Appearance: colorless to pale liquid

-- Ionicity: nonionic

--pH: 3-5(1% solution)

--Solubility: easily soluble in water

--Stability: stable to acid, alkali and electrolytes

[Properties and fields of application]

--Pretreatment at 80-90 ℃ can achieve traditional oxygen bleaching scouring effect, great energy-saving.

--Suitable for cotton, polyester-cotton fabric, yarn and fiber one-time pretreatment, good effect, less weight loss and good hand feeling.

--Free of AEPO any harmful chemical substances and meet the requirements of environmental protection, reduce COD/BOD.

--Reduce wrinkle of the blended fabric in high-temperature conditions and the tear and bursting strength are not damaged

[Application]

High concentration product can dilute 3 times.

Dipping :(cotton knit, cheese)

Scouring agent: 1-2g/L

NaOH: 2g/L

H2O2: 5 g/L

Hydrogen peroxide activator: 2-3g/L

[Process]

Bath ratio 1:8, with 2-3℃/ min heating to 80-85℃, heat preservation for 60-90 min.

[Packing and storage]

-- Packing: 125 kg/polyethylene drum

-- Storage: Keep it cool and dry,6 months in a sealed container.

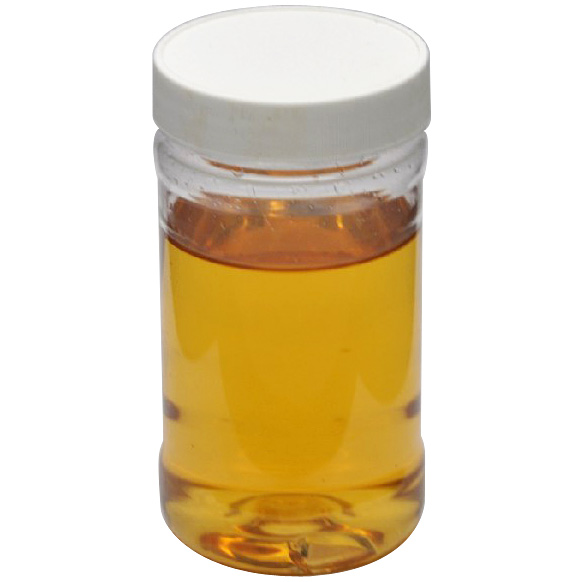

Wax Removing Agent 1012B

Wax removing agent, also call wax cleaning agent, when cotton textiles appear wax spot, will appear water repellent and dye repellent, then result in a variety of problems and irreparable defect, seriously affect the quality of printing products, wax removing agent an emulsification remove textile especially on T/C wax spot, wax line effectively, for the next working procedure provides a clean, fresh and homogeneous semi-product.

[Main composition]

A variety of powerful emulsifier compound with content

[General properties]

Appearance: undertint to colorless thick liquid

Ionicity: Nonionic

pH value: 5 ~ 7.5

Solubility: soluble in water

[Product features]

Wax removing agent 1012B is a variety of brute force emulsifier, can emulsification remove textile especially on T/C wax spot, wax line effectively, for the next working procedure provides a clean, fresh and homogeneous semi-product.

Wax removing agent 1012B is simple to use and can avoid complicated and high consumption problem of traditional re-work process.

Wax removing agent 1012B is not resistant to strong base.

Good quality with low price.

[Application]

Pad dyeing: 20-25 g/l

Padding - drying

Specific dosage and conditions should be according to the weight of the wax spot, etc.

[Packaging and storage]

125 kg/polyethylene drum, at room temperature quality guarantee period 1 year.

[Notes]

The data contained in this literature are based on our current knowledge and experience. It is imperative that it be tested to determine, to your satisfaction, whether it is suitable for your intended use and application. We shall not take any responsibility in any situation for improper use.

[Sample supply]

If you need samples for testing, please feel free to contact us, we will recommend suitable products according to your requirement.

[Order MOQ]

Normally, order MOQ is 3 tons per model and we can offer lowest price with more quantity.

[Shipment]

We can support LCL shipment and FCL shipment, for LCL shipment, we will pack the goods with wool pallet to save the products during transportation.

[Quotation]

According to your order quantity, we can supply FOB, CIF, EXW price.

在线联系供应商

Other supplier products

| Quaternized Amino Silicone Oil JA | Quaternary silicone oil is the special textile softener which developed by organic silicone modified technology. modified traditional amino silic... | |

| Sulfur Dye Fixing Agent HT-LG26 | [Brief information ] Sulfur dyefixing agent is a formaldehyde-free fixing agent, mainly used in post-treatment of vulcanized dye fabrics and obvio... | |

| Antisatic Agent KD | This product is suitable for polyester, polyamide, such as polyvinyl chloride staple fibre spun synthetic fiber spinning static elimination, with e... | |

| Fixing Agent for Acid Dyes SP | [Fixing Agent for Acid Dyes General Information] Fixing agent for acid dyes will be deposited on the surface of the fiber, plugging the pores of a... | |

| Wet Rubbing Fastness Improver Agent 809 | Original wet rubbing fastness improveragent is poor deep dyeing for direct, reactive, indigo blue and sulfur dyestuffs, especially for dark black, ... |

Same products

| TPU Compound Fabric/TPU Compound Film | 卖方: Shanghai MSD International Trade Co., Ltd | Polyurethanes used as insulator effectively improve the energy efficiency of buildings, transport... | |

| Shirley Moisture Permeability Tester | 卖方: Standard International Group (HK) Limited | Introduction Shirley moisture permeability tester is used to detect water vapor permeability o... | |

| Digital Pneumatic Stiffness Tester/Stiffness Tester Pneumatic | 卖方: Standard International Group (HK) Limited | A plunger of 25.4 mm (1 in) diameter pushes the fabric through a 38 mm (1.5 in) diameter orific... | |

| Bundesmann Rain Tester | 卖方: Standard International Group (HK) Limited | Introduction The device is a practical test method for rainfall, applicable to clothing prod... | |

| Spray Rating Tester | 卖方: Standard International Group (HK) Limited | Standards: ISO 4920. BS EN 24920. BS 3702. GB/T 4745. AATCC 22. M&S P23. NEXT 23 Applicatio... |