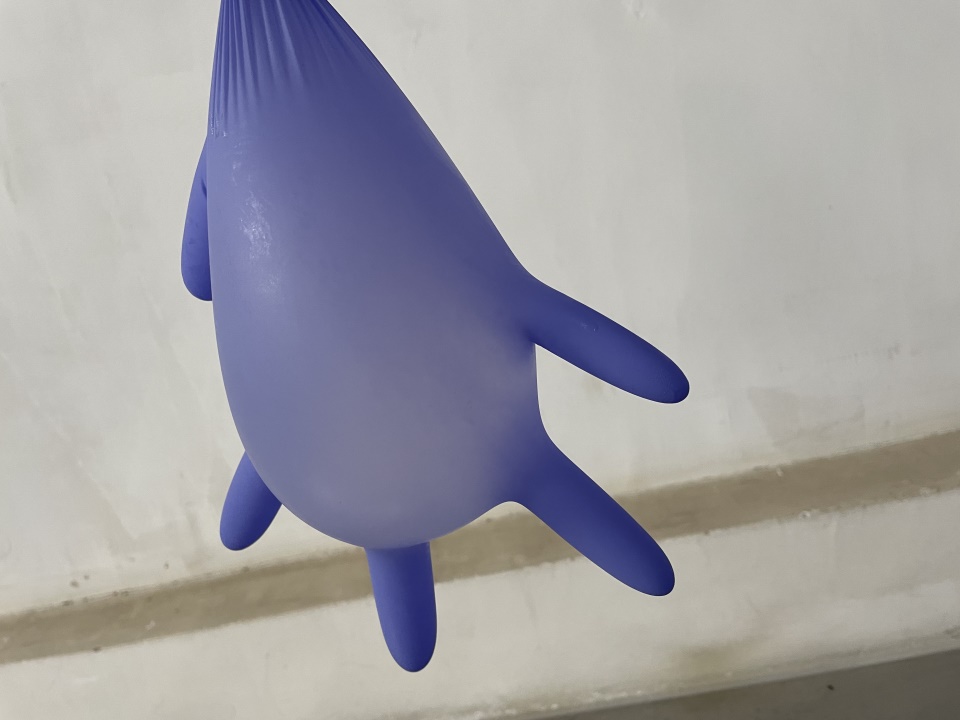

Glove inspection service quality QC on-site inspection

Inspectionshelp to minimize the risk of non conformity and ensure they meet customer and industry standards. This serves to protect your business interests, help manage your risk and ensure quality products are manufactured and delivered to their final destination according to your specifications.

As an independent third-party, HQC inspection services to foreign manufacturers, retailers, traders, groups, small and medium-sized businesses, governments and other buyers of materials and products from China.

1.Quality evaluation on pre-production samples.

The evaluation is based on the inspection of all or more than half of the samples batch. Based on our specification file, drawings, layouts, and Quality Benchmark, we inspect the goods, record results and can conduct a functional check. Any discrepancy with standards that we pick up is listed and solutions to improve the defective non-compliant samples are talked over.

2.Initial production inspection.

Our inspector arranges a visit in order to inspect the means of production, raw material inventory, and input components as well as go through technical aspects of the product itself.

3.During production inspection.

This is often an impromptu visit to the factory during production. The aim is to identify non conformity is any and the quantity affected at an early stage. Following to the DuPro inspection, solutions are implemented depending on the situation. This type of inspection also involves a published report.

4.Pre-shipment inspection.

The inspection just prior to shipment allows us to verify that the packaging, final product, and marking comply with the requirements. This inspection consists of a random selection of a certain percentage of the balance. Our inspector is also present during the packing to verify the products condition prior to shipping. Final inspection report follow these inspections.

Quotes from our inspectors :

"In order to ensure a certain quality level, everything should be defined clearly before the order."

"A final inspection or pre shipment inspection is mostly relevant if risks of defects and non conformity are low."

" When dealing for a first time with a supplier, better do an inline inspection rather than discovering non conformity just before shipment".

"We're in China, it's a different mindset, and quality standards are not the same as of other countries."

在线联系供应商

Other supplier products

| Pre-shipment food inspection service for Chinese third-party products | During production inspection is ideal for shipments of substantial quantities; Product lines with continuous production; Strict requirements for on... | |

| Wooden massage stick Products- Third Party Inspection 100% Quality Control | The in-process quality check is designed to provide early warning of quality or other problems arising during production and which may delay shipme... | |

| Accessories quality control China quality inspection service | PRODUCT QUALITY CONTROL SERVICES, include:Product inspection;Loading supervision;Full inspection;Product audit;Process audit;Damage investigation... | |

| Pre-shipment glasses inspection service for Chinese third-party products | The in-process quality check is designed to provide early warning of quality or other problems arising during production and which may delay shipme... | |

| Bamboo cutting board Products- Third Party Inspection 100% Quality Control | In order to ensure good quality and prompt delivery for big orders or long-term orders, we send our inspectors to the factory to track the whole pr... |