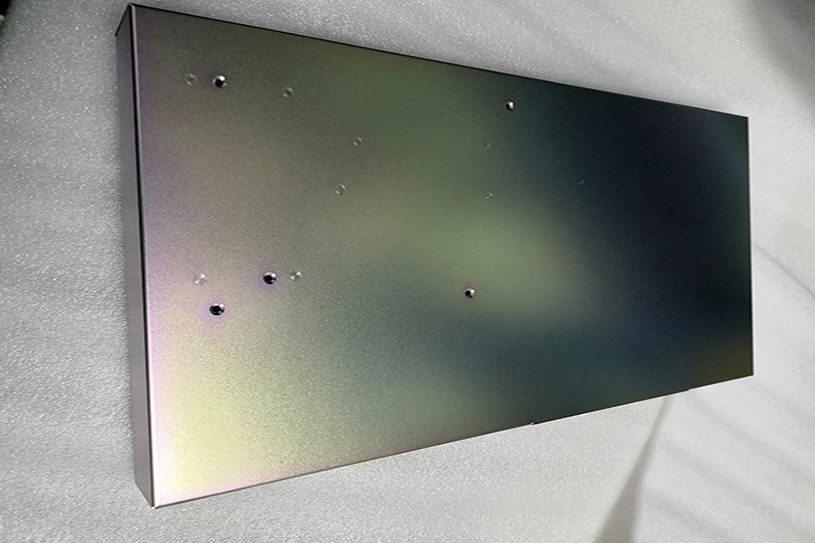

Stamping Computer Enclosures

Surface treatment:

in the photo we not show the surface treatment but we could offer the powder coating and anodizing and silk print and color plating and laser logo and so on.

Process:

stamping

Material:

Powder coating,Painting,hot dip galvanized(Mild Steel)Brush finish,powder coating,electro polish,mirro(stainless steel)Powder coating,anodize,brush(aluminum).

We offer customized service depend on your require.

Tolerance:0.1mm

We also offer process like: blanking – bending – welding –riveting and so on.

Packaging Details

custom oem sheet metal electric tele exchange enclosure

Our Advantages:

1. Quick Response and quickly action,your inquiry will be replied in 24 hours

2. Competitive Price directly from in housing plant.

3. High quality due to first-hand control in factory.(control each step)

4. OEM/ODM:custom fabrication according to your drawings or samples.

5. Flexibility:small orders are acceptable for quick delivery and help you reduce the stock cost.

Computer enclosure or pc enclosure is our main product. We also provide waterproof outdoor computer enclosure and industrial computer monitor enclosuresfor you.

As aprofessional sheet metal products manufacturer, we provide metal fabrication service china,china welding fabrication, cheap server rack cabinetand etc. Want to know more? Please contact us.

在线联系供应商

Other supplier products

| Custom Aluminum Parts | As a professional CNC metal parts manufacturer, HSJ is specialized in billet aluminum parts and custom aluminum component manufacturing. Material ... | |

| SHEET METAL STAMPING | Sheet metal stamping (also known as metal pressing and forming) is the process of placing flat sheet metal in either blank or coil form into a stam... | |

| Electroplated & Anodized Enclosure | As a professsional stainless steel fabrication factory, Shenzhen HSJ Metal Fabrication Co., Ltd. has rich experience in providing professional shee... | |

| CNC Custom Aluminum Parts | Custom Aluminum CNCParts Material: aluminum Process: Cnc machine-wire drawing-reveting-anodizing-silk printing Color: steel color(we offe... | |

| Sheet Metal Cabinets | Sheet metal has the characteristics of light weight, high strength, electrical conductivity (can be used for electromagnetic shielding), low cost, ... |

Same products

| ARM Cortex-A53 控制器支持 Linux Ubuntu,具有 4DI 到脉冲计数/数据控制,适用于智能工厂 | 卖方: 钡铼技术 | ARMxy BL340 系列是基于 Allwinner T507-H 处理器的工业 ARM 控制器,配备四核 ARM Cortex-A53 CPU,最高可达 1.4GHz。它具有 8/16GB ... | |

| ARM 2*Cortex-A53 电脑带2DI+2DO 支持Ubuntu储能 | 卖方: 钡铼技术 | ARMxy BL340 系列是基于 Allwinner T507-H 处理器的工业 ARM 控制器,配备四核 ARM Cortex-A53 CPU,最高可达 1.4GHz。它具有 8/16GB ... | |

| T507-H 处理器控制器 8GB eMMC 1GB DDR4 + 4RS485 支持 Linux 用于边缘计算 | 卖方: 钡铼技术 | ARMxy BL340 系列是基于 Allwinner T507-H 处理器的工业 ARM 控制器,配备四核 ARM Cortex-A53 CPU,最高可达 1.4GHz。它具有 8/16GB ... | |

| ARM 计算机 8GB eMMC 1GB DDR4+16GPIO 支持工业物联网的 Docker。 | 卖方: 钡铼技术 | ARMxy BL340 系列是基于 Allwinner T507-H 处理器的工业 ARM 控制器,配备四核 ARM Cortex-A53 CPU,最高可达 1.4GHz。它具有 8/16GB ... | |

| 1.4GHz 计算机配备 4*PGIO,支持 Ubuntu 用于储能 ARM 计算机。 | 卖方: 钡铼技术 | ARMxy BL340 系列是基于 Allwinner T507-H 处理器的工业 ARM 控制器,配备四核 ARM Cortex-A53 CPU,最高可达 1.4GHz。它具有 8/16GB ... |