PIPELINE COATING

Internal coating of pipelinesis an economical and practical practical solution to maintain pipeline, which can provide continuous protection for the pipeline and prevent the pipeline from the destructive effects of corrosion. Internal epoxy coating for pipelinesis one of the most reliable anti-corrosion methods used in industry today.

Types of Pipeline Coating

High-Build Epoxy Drinking Water Tank Anticorrosive Paint(FDA)

Polyurea Elastomer Anticorrosive Coating

Internal Drag Reducing Epoxy Anticorrosive Coating

High-build Epoxy Coal Tar Acid and Akali Resistance Paint

Chlorinated Rubber Asphalt Paint

High-build Epoxy Coal Tar Finish

Non-solvent Liquid Epoxy Paint

Solvent-Free Polyurethane Anticorrosive Coating

Coating For Different Pipelines

Process Pipeline

When a new petrochemical plant is built, the processing pipeline is very complicated, with different media and temperatures. Generally, inorganic zinc silicate primer is used as a general anti-corrosion and high-temperature resistant coating. The zinc powder content in the dry film of the inorganic zinc silicate primer is 80%, which can withstand high temperatures of 400°C, and the dry film thickness is 50-75μm. It should not be too thick, otherwise, the coating film will crack due to the cold wall effect of the pipeline. The design of the coating system of the processing pipeline should consider the limitation of working temperature, the difference between insulation and non-insulation, and material/substrate.

Insulation is mainly to prevent energy loss. For the surface of non-insulated pipelines below 120℃, the matching coating system is epoxy/inorganic zinc silicate + epoxy coating paint + aliphatic polyurethane topcoat. Within 120℃, epoxy paint and polyurethane paint can be used. At 120-230℃, acrylic silicone or phenolic epoxy paint can be used. At 200-400°C, inorganic zinc silicate is used. At 400-600℃, organic silicon aluminum paint is the main choice. If the paint on the surface of stainless steel, zinc, or aluminum paint should not be used to avoid galvanic corrosion.

Buried pipeline

The outer wall of the buried pipeline is mainly corroded by the soil. When choosing the anti-corrosion coating, its corrosion characteristics must be considered comprehensively. At present, the corrosion protection of pipelines adopts anti-corrosion coating and cathodic protection. For buried pipelines in petrochemical plants, epoxy asphalt coatings, modified thick-build epoxy coatings, solvent-free phenolic epoxy coatings, polyurethane foam-polyethylene anticorrosive insulation layer are practically used.

Gas pipeline

The internal coating materials for natural gas pipelines mainly include epoxy powder coatings, liquid epoxy coatings, and phenolic epoxy coating. When the epoxy resin coating is cured, the volume shrinkage is small, the thermal expansion coefficient is small, and the temperature and stress resistance is strong. It is suitable for high-pressure gas pipelines.

Sewage pipeline

The outer wall coating system of steel sewage pipes used an epoxy coal tar two-cloth-five-oil FRP system. New types of anti-corrosive coating systems of buried pipelines commonly use epoxy zinc-rich paint as a primer. Epoxy coal tar mortar paint, modified high build epoxy paint, solvent-free epoxy glass flake, and vinyl ester glass flake paint are for the choice of topcoat. The coating system has no pinhole defects, needs no glass cloth, has excellent insulation, anti-microbial corrosion, and good chemical resistance. The coating film can reach the required film thickness with one time layer, with the advantages of a simple construction process, low surface treatment cost, and short construction period. The inner wall of the steel pipe can also be matched with the same coating system.

As one of the most professional zinc rich paint suppliers,we provide china coatings, marine boat paint, oil Pipeline Coating, polyurea pipe coating, polyurethane pipe coating, water pipe coating, gas Pipeline Coating, marine grade paintand etc.

在线联系供应商

Other supplier products

| Asphalt Antifouling Paint (for ships) | Asphalt antifouling coatingis one component, it is formulated with asphalt, solvent, extender pigment and additives. It has excellent water resista... | |

| High-build Epoxy Coal Tar Primer | High build primer surfaceris formulated with special epoxy resin, coal tar pitch paint, antirust pigment, solvents and additives. It has fast dryin... | |

| CHLOROSULFONATED POLYETHYLENE PAINT | Chlorosulfonated polyethyleneis prepared by chlorinating and sulfonating polyethylene from the mixed gas of chlorine and sulfur dioxide, which has ... | |

| High Build Epoxy Glass Flake Anticorrosive Paint | High-build Epoxy china glass flake paintis based on epoxy resin, combined with glass flakes as the main anti-rust pigment, and other anti-rust pigm... | |

| Vinyl Perchloride Putty | Vinyl perchloride putty decorationis made of vinyl perchloride resin, alkyd resin, pigments, extender pigments and organic solvents. It has good pe... |

Same products

| Aluminium Garden Ornaments | 卖方: LianJiang Metals Company | Aluminium Garden Ornaments Aluminum garden ornamentsare decorative pieces made of aluminum that ... | |

| 蓝翠鸟 水包砂 | 立体仿石 外墙环保涂料 | 卖方: 中山蓝翠鸟新型环保材料有限公司 | 产品概述 蓝翠鸟水包砂外墙涂料,融合立体仿石质感与环保水性科技,为建筑塑造坚固而美观的外衣。其丰富的石材肌理与色彩,让外墙具备设计感的同时,也拥有出色的耐久与防护性能。 产品优势 ... | |

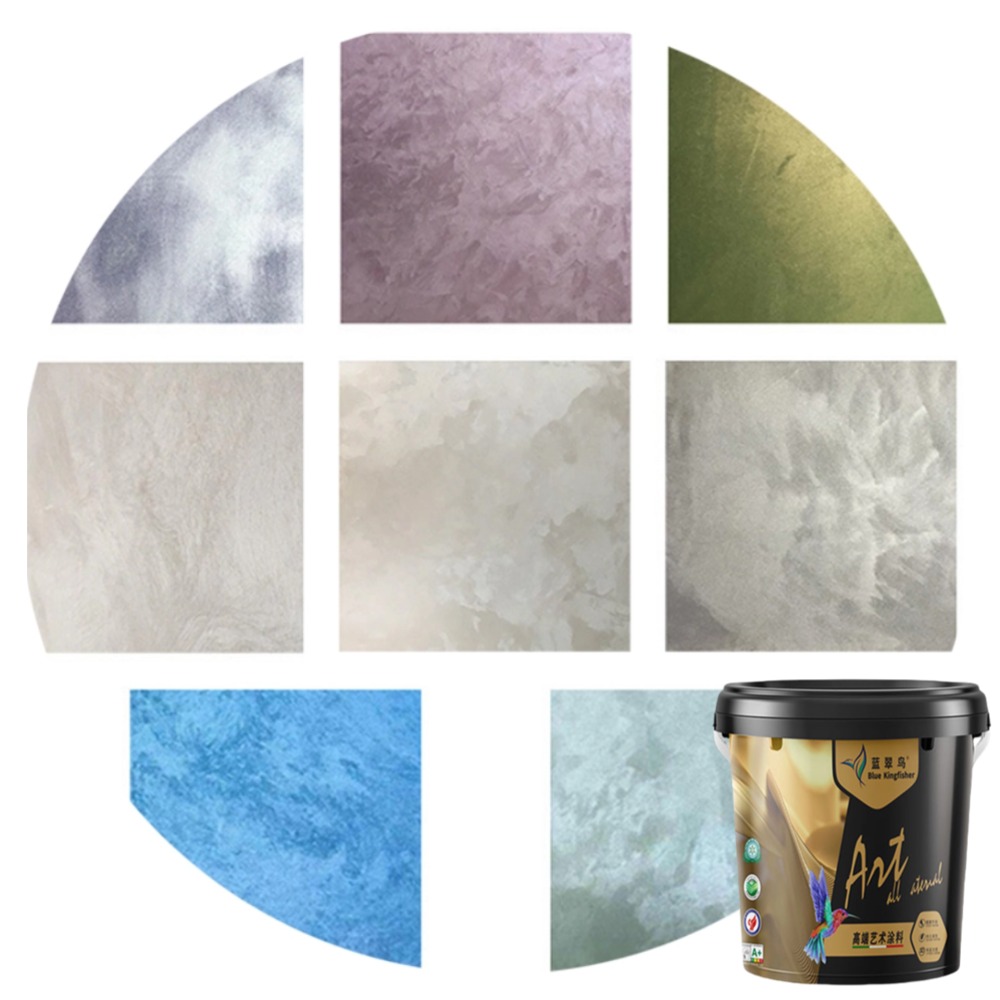

| 蓝翠鸟 设计师系列天鹅绒艺术漆 | 微光质感 背景墙涂料 | 卖方: 中山蓝翠鸟新型环保材料有限公司 | 产品概述 这款天鹅绒艺术漆是提升空间设计感的秘密武器。它特有的柔光微哑质感,能瞬间让墙面告别平淡,带来低调的内敛奢华。非常适合用于打造客厅主题墙、餐厅背景或工作室墙面,无需复杂装饰,仅凭墙... | |

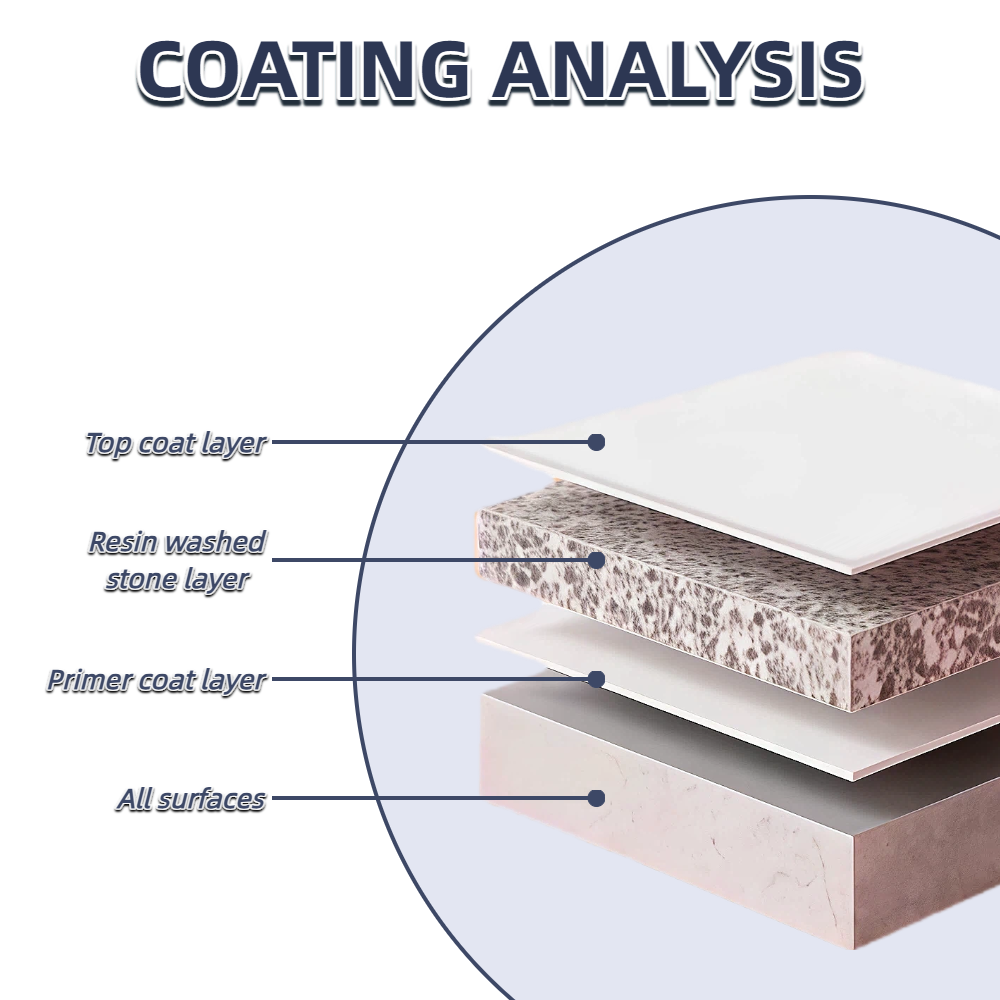

| 蓝翠鸟免水洗树脂水洗石 | 一刮成型 墙面地面皆宜 | 卖方: 中山蓝翠鸟新型环保材料有限公司 | 产品概述 蓝翠鸟免水洗树脂水洗石,是一款革命性的装饰材料,其核心“一刮成型”工艺彻底颠覆了传统水洗石的复杂施工流程。可在墙面或地面快速塑造出坚固、耐磨且富有天然石子肌理... | |

| 铺贴瓷砖更轻松 蓝翠鸟膏品质瓷砖胶 厂家批发 | 卖方: 中山蓝翠鸟新型环保材料有限公司 | 核心性能 名称:瓷砖胶 主要材质:水泥、石英砂、聚合物改性剂等 形态:粉状干混材料(加水搅拌成膏状) 规格:20kg / 袋 优势: 1、粘结力强,能有效防止瓷砖、石材出现空鼓、脱落... |