SMC/BMC Antenna Reflector

High precision, high efficiency, and high gain

The most important job of using smc/bmcfor the manufacture of antennas is to fully exploit its features and achieve high precision in antenna design from product design and process. Under the condition that the shrinkage ratio of the material and the SMC molding shrinkage rate have been considered in the mold size design, the SMC antenna reflective surface has a smaller shape from the original design paraboloid after molding. That is, the accuracy of the SMC molded antenna is completely guaranteed by the accuracy of the mold. The rms value of the SMC antenna molded integral reflection surface is 0.25 mm, and the rms value of the single-piece reflection surface of the split antenna is less than 0.3 mm, and the rms value of the reflective surface after assembly is less than 0.6 mm.

Corrosion Resistance ofSMCBMC reflector

Conventional antenna materials such as aluminum plates and steel plates are made of metal materials, not as good as SMC which as a non-metal dielectric composite material in terms of acid resistance, alkali, salt, and corrosion resistance. The Pikington laboratory in the United States used infrared to analyze the surface of SMC materials and found that its surface is covered by additives, resin, and very fine calcium acid filler. It has good acid resistance, water resistance and corrosion resistance. The antenna reflection made by this material is solved the disadvantage of the traditional metal material antenna is easy to corrode. In coastal areas, rainy, humid areas and areas with excessive acid rain, the anti-corrosion advantages of SMC molded antennas are particularly prominent. The SMC molded antenna samples were placed in 130 highly corrosive chemical environments at an ambient temperature of 50 ° C. The results showed that the test samples showed little or no change.

Long LifeSMC/BMC Antenna Reflector

The average aluminum plate antenna is as small as 2-3 years in the coastal area, and more often 4-6 years, and it will generally be damaged by salt spray erosion and aging. The most obvious example is the cable TV (CATV) in Taiwan, which was built earlier than the mainland. It is estimated that there are nearly 1000 satellite TV receiving antennas on the island, all built in the mid-1980s, all of which were aluminum plate antennas, until the early 1990s. , that is, has begun to replace. The service life of SMC molded antennas is generally more than 15 years; PROMLIN's prototype SMC molded antennas in 1985 are still working normally, and they are subject to typhoons and heavy rain every year.

Strong Wind Resistance ofSMC/BMC Antenna Reflector

Since the antenna reflection surface is designed during the molding process, multiple longitudinal and circumferential rib structures are designed. According to the structural strength calculation, the SMC antenna can withstand a wind load of 45 m/s, which shows its remarkable structural rigidity and strength.

Special Reflective Layer Technology ofSMC/BMC Antenna Reflector

The reflective surface of the SMC antenna uses a metal aluminum mesh as a reflective layer of electromagnetic waves. The aluminum mesh in the finished antenna is evenly embedded under the surface SMC, which can reflect electromagnetic waves and insulate the atmosphere, and plays a good protective role.

Good consistency, no deformation, easy to transport and install

Because SMC antenna adopts membrane pressure technology under high temperature and high pressure. Its material properties and processing technology determine the unparalleled consistency of SMC antennas with other antennas. This not only ensures the accuracy and high gain of the antenna, but also is very easy to install and debug. SMC, commonly known as "glass reinforced plastic", has the characteristics of no deformation, which eliminates the adverse effects of antenna deformation on the satellite receiving system during transportation.

If you want to know more applications of bmc composite, please contact us.

As a bmc compoundmanufacturer, we will do our best to meet all the needs of customers.

在线联系供应商

Other supplier products

| BMC/SMC Molded Products | What Is SMC Plastic? SMC, BMC thermosetting plastic products are produced by BMC SMCplastic molding process. BMC/SMC Motor Plastic SMC/BMC e... | |

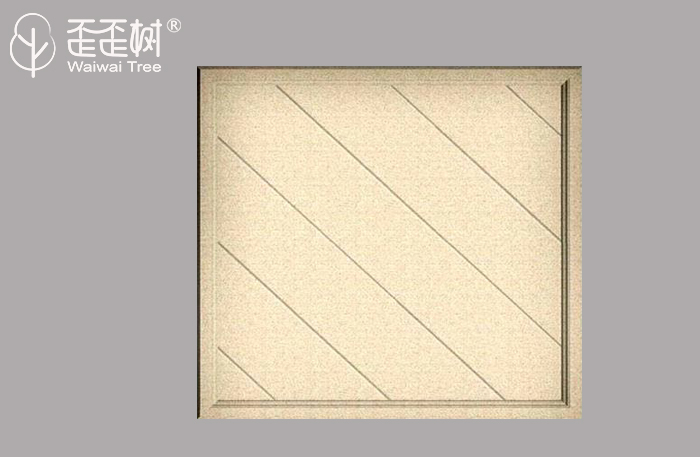

| BMC, SMC, GRP, GFK Ceiling | The BMCcompositeprecision molds produced by Waiwai Tree have the characteristics of low energy consumption; our SMC and BMC moldinghave no waste, a... | |

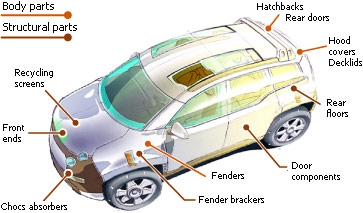

| SMC Automotive Molding, Car Mould | SMC AutomotiveMolding, Car Mould Cars, buses, trucks, transport and special vehicles • Weight: Parts made from sheet molding compound (... | |

| BMC, SMC, GRP, GFK Wall Panel | BMCcompositewall panel is a new generation of high performance building partition board made of a variety of building materials instead of traditio... | |

| SMC Cable Braket | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The material of the column and the pin is also made by... |

Same products

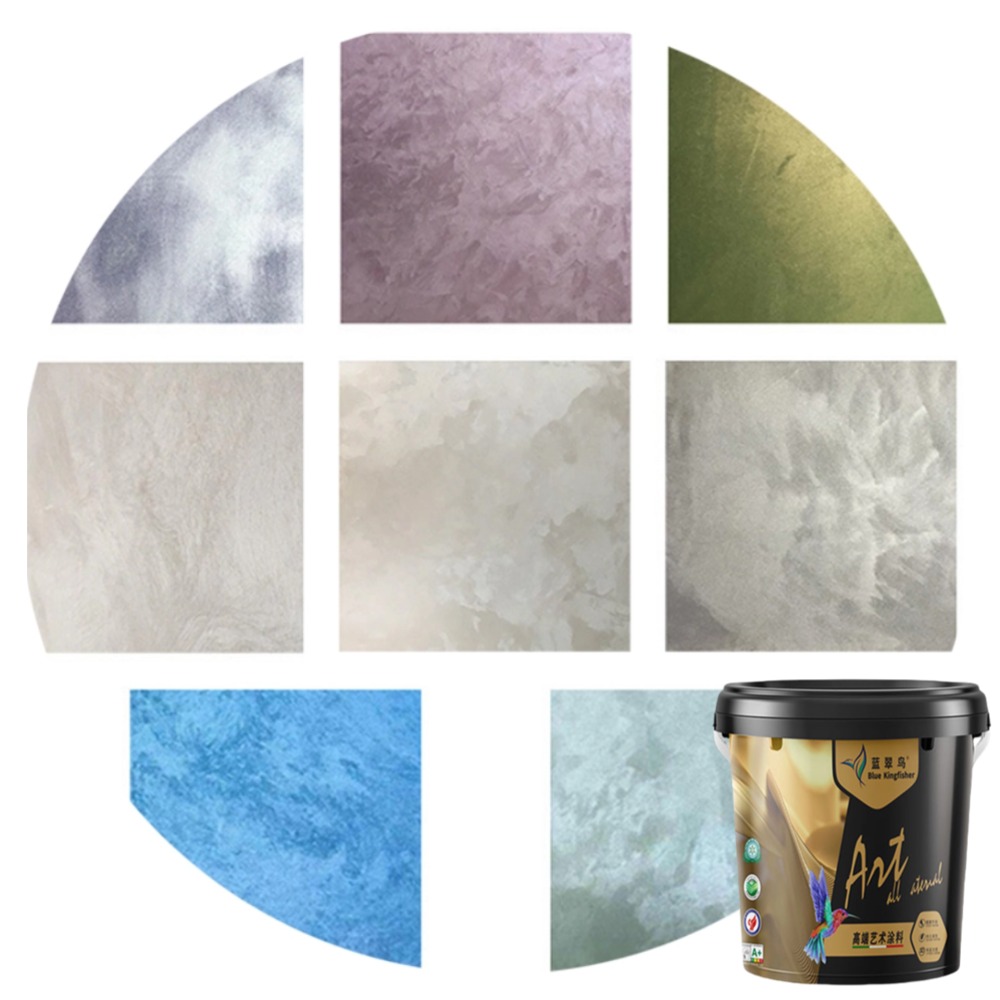

| 威尼斯灰泥——制造商直供精品民宿与小型商业空间,温暖质感,经济实惠,库存充足 | 卖方: 中山蓝翠鸟新型环保材料有限公司 | 产品概述 蓝翠鸟威尼斯灰泥是精品民宿与小型商业空间的高性价比艺术墙面材料,以经济型天然矿物原料、环保水性树脂为基料,质感温暖柔和、施工便捷、性价比高,适配精品民宿客房墙面、小型咖啡馆主题墙面、... | |

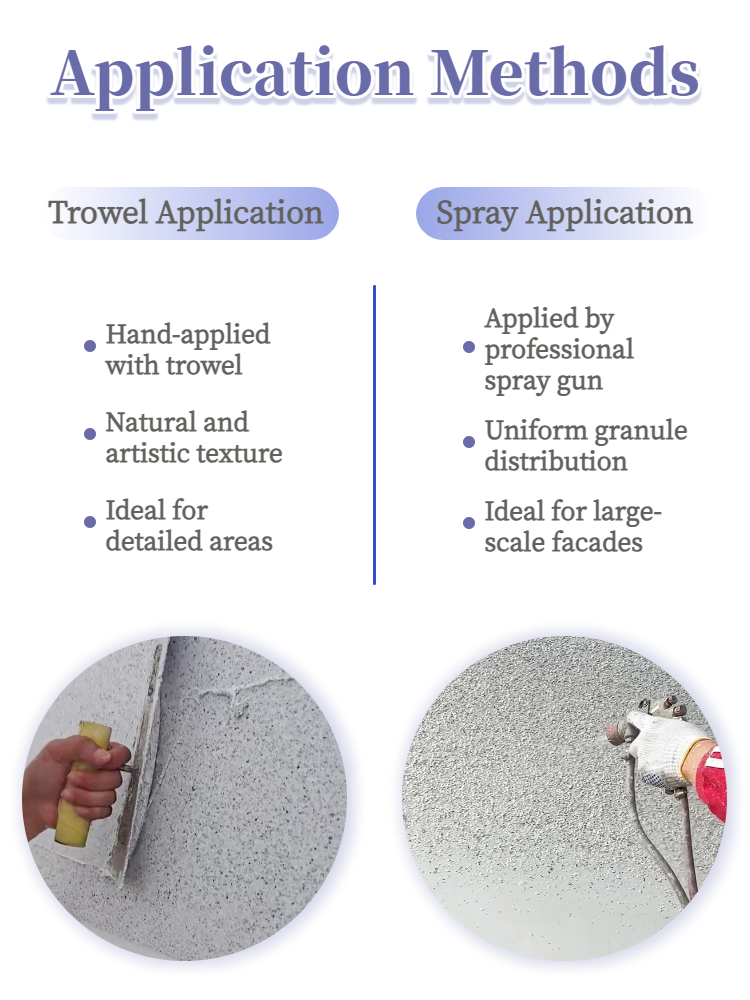

| 蓝翠鸟 水包砂 | 立体仿石 外墙环保涂料 | 卖方: 中山蓝翠鸟新型环保材料有限公司 | 产品概述 蓝翠鸟水包砂外墙涂料,融合立体仿石质感与环保水性科技,为建筑塑造坚固而美观的外衣。其丰富的石材肌理与色彩,让外墙具备设计感的同时,也拥有出色的耐久与防护性能。 产品优势 ... | |

| 蓝翠鸟 设计师系列天鹅绒艺术漆 | 微光质感 背景墙涂料 | 卖方: 中山蓝翠鸟新型环保材料有限公司 | 产品概述 这款天鹅绒艺术漆是提升空间设计感的秘密武器。它特有的柔光微哑质感,能瞬间让墙面告别平淡,带来低调的内敛奢华。非常适合用于打造客厅主题墙、餐厅背景或工作室墙面,无需复杂装饰,仅凭墙... | |

| 蓝翠鸟免水洗树脂水洗石 | 一刮成型 墙面地面皆宜 | 卖方: 中山蓝翠鸟新型环保材料有限公司 | 产品概述 蓝翠鸟免水洗树脂水洗石,是一款革命性的装饰材料,其核心“一刮成型”工艺彻底颠覆了传统水洗石的复杂施工流程。可在墙面或地面快速塑造出坚固、耐磨且富有天然石子肌理... | |

| 铺贴瓷砖更轻松 蓝翠鸟膏品质瓷砖胶 厂家批发 | 卖方: 中山蓝翠鸟新型环保材料有限公司 | 核心性能 名称:瓷砖胶 主要材质:水泥、石英砂、聚合物改性剂等 形态:粉状干混材料(加水搅拌成膏状) 规格:20kg / 袋 优势: 1、粘结力强,能有效防止瓷砖、石材出现空鼓、脱落... |